All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

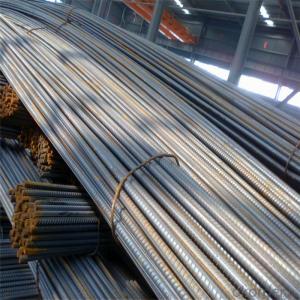

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the advantages of using high-strength steel in the construction of buildings and infrastructure?

There are several advantages of using high-strength steel in the construction of buildings and infrastructure. Firstly, high-strength steel allows for the creation of lighter structures, which reduces material and transportation costs. Additionally, it provides enhanced structural performance, offering greater resistance to forces such as earthquakes, wind, and impacts. High-strength steel also allows for longer spans and larger column-free spaces, providing flexibility in architectural design. Furthermore, its durability and resistance to corrosion results in a longer lifespan for the structures, reducing maintenance and replacement costs. Overall, high-strength steel offers economic, structural, and aesthetic benefits, making it a preferred choice for construction projects.

How is steel employed in the automotive industry to enhance safety and crash performance?

Steel is employed in the automotive industry to enhance safety and crash performance by providing strength and durability. It is used in various components, such as the vehicle's frame, body panels, and safety cages, to absorb and distribute impact forces during a crash. This helps to protect the passengers by minimizing the deformation of the vehicle's structure and reducing the likelihood of injury.

What is precipitation hardening, and how is it achieved in steel?

Precipitation hardening is a heat treatment process used to enhance the strength and hardness of certain alloys, including steel. It involves the formation of fine particles or precipitates within the metal's microstructure, which hinder the dislocation movement and increase the material's strength.

In steel, precipitation hardening is achieved through a specific sequence of heating and cooling steps. Firstly, the steel is heated to a high temperature, typically above its critical temperature, to dissolve any existing precipitates. Then, it is rapidly cooled, or quenched, to room temperature to trap the dissolved alloying elements in a supersaturated solid solution. Afterward, the steel is subjected to a low-temperature aging treatment, usually around 400-600°C, to allow the formation of finely dispersed precipitates.

During the aging process, these precipitates grow and strengthen the steel by hindering the movement of dislocations, which are responsible for plastic deformation. The size, distribution, and composition of the precipitates, as well as the duration of the aging treatment, play crucial roles in determining the final properties of the steel, such as its strength, hardness, and toughness. Precipitation hardening is a widely used technique to improve the mechanical performance of steel in various industries, including aerospace, automotive, and tool manufacturing.

Wholesale Special Steel from supplier in Ecuador

Thank you for considering us as your leading supplier of Special Steel products in Ecuador. As a subsidiary of CNBM, we have the resources and expertise to provide comprehensive procurement services tailored to your specific needs.

Our extensive range of Special Steel products, including stainless steel, alloy steel, and tool steel, sets us apart from the competition. We have a diverse inventory to meet your requirements and offer valuable insights and knowledge from our years of experience in the Ecuadorian market.

We are committed to providing exceptional customer service and ensuring that your Special Steel needs are met efficiently. Our dedicated team of professionals is available to assist you at every step of the procurement process, from initial inquiry to final delivery. We strive to establish long-term partnerships with our clients, offering competitive prices, reliable products, and technical support to ensure your satisfaction.

By choosing us as your trusted Special Steel supplier in Ecuador, you will benefit from our extensive inventory, industry expertise, and exceptional service. We look forward to serving you and contributing to the success of your projects.

Our extensive range of Special Steel products, including stainless steel, alloy steel, and tool steel, sets us apart from the competition. We have a diverse inventory to meet your requirements and offer valuable insights and knowledge from our years of experience in the Ecuadorian market.

We are committed to providing exceptional customer service and ensuring that your Special Steel needs are met efficiently. Our dedicated team of professionals is available to assist you at every step of the procurement process, from initial inquiry to final delivery. We strive to establish long-term partnerships with our clients, offering competitive prices, reliable products, and technical support to ensure your satisfaction.

By choosing us as your trusted Special Steel supplier in Ecuador, you will benefit from our extensive inventory, industry expertise, and exceptional service. We look forward to serving you and contributing to the success of your projects.