All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

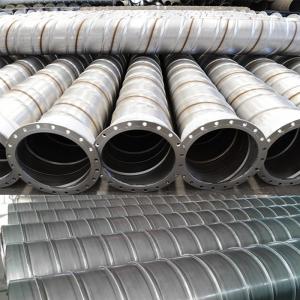

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

Can a welded steel pipe be used for stadium construction?

Yes, a welded steel pipe can be used for stadium construction. Welded steel pipes are commonly used in construction projects, including stadiums, due to their strength, durability, and ability to withstand heavy loads. They provide structural support and can be used for various applications such as framing, piling, and underground utility systems.

Can welded steel pipe be used for furniture manufacturing?

Yes, welded steel pipe can be used for furniture manufacturing. It is a durable and strong material that can be shaped and manipulated to create various furniture designs. Welded steel pipes are commonly used in the construction of furniture frames, legs, and supports, providing stability and longevity to the finished product.

Can welded steel pipes be used for transporting liquids?

Yes, welded steel pipes can be used for transporting liquids. Welded steel pipes are commonly used in various industries such as oil and gas, water treatment, and chemical processing for transporting liquids safely and efficiently. The welding process ensures the pipes are strong, durable, and leak-proof, making them suitable for liquid transportation applications.

Can welded steel pipes be used for conveying sewage in a corrosive environment?

Yes, welded steel pipes can be used for conveying sewage in a corrosive environment. However, it is important to select the appropriate type of steel and apply protective coatings or linings to prevent corrosion and ensure the longevity and durability of the pipes. Regular maintenance and inspections are also necessary to identify and address any corrosion issues.

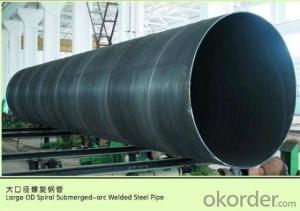

What is the difference between ERW (Electric Resistance Welded) and SAW (Submerged Arc Welded) steel pipes?

ERW (Electric Resistance Welded) steel pipes are manufactured by passing a high-frequency current through the metal, which causes the edges to heat and fuse together. This welding process results in a strong and smooth joint. On the other hand, SAW (Submerged Arc Welded) steel pipes involve a welding process where an arc is submerged under a layer of granular flux. This creates a protective environment and produces a high-quality weld with excellent penetration and deposition rates. In summary, ERW pipes are made by fusing the edges using electric resistance, while SAW pipes use an arc submerged in flux for welding.

Wholesale Welded Steel Pipe from supplier in Czech Republic

We are a Welded Steel Pipe supplier serving the Czech Republic, mainly engaged in the sale, quotation, and technical support services of various Welded Steel Pipe products in the Czech Republic region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Welded Steel Pipe procurement services in the Czech Republic. Not only do we have a wide range of Welded Steel Pipe products, but after years of market development in the Czech Republic, we can also provide valuable experience for your projects.