All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

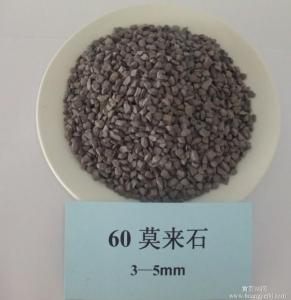

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

Explain the role of binders and additives in the formulation of refractory castables.

Binders and additives play a crucial role in the formulation of refractory castables. Binders are substances that help hold the refractory particles together, providing strength and stability to the castable. They act as a bonding agent, ensuring that the refractory material maintains its shape and structure during application and drying. Common binders include clay, cement, and various organic or inorganic polymers.

Additives, on the other hand, enhance the properties and performance of refractory castables. They can improve the workability and flowability of the castable, making it easier to handle and apply. Additives also contribute to the overall strength, density, and thermal conductivity of the refractory material. They may enhance the resistance to thermal shock, corrosion, or abrasion, depending on the specific additives used.

Overall, binders and additives are essential components in the formulation of refractory castables as they determine the mechanical, thermal, and chemical properties of the material. Their proper selection and incorporation are vital to ensure the castable's ability to withstand high temperatures and harsh operating conditions in various industrial applications.

Discuss the role of bauxite in the production of refractory bricks.

Bauxite plays a crucial role in the production of refractory bricks as it is the primary source of aluminum oxide, which is a key component in their composition. Aluminum oxide provides the necessary heat resistance, strength, and chemical stability required for refractory bricks to withstand high temperatures and harsh environments. Bauxite is typically processed and refined to extract aluminum oxide, which is then combined with other materials such as clay, silica, and other additives to form refractory bricks. Its abundance and favorable properties make bauxite an essential raw material in the production of refractory bricks.

What are the properties of chrome ore-based refractory materials?

Chrome ore-based refractory materials have several key properties. Firstly, they exhibit excellent heat resistance, making them capable of withstanding high temperatures without significant deformation or degradation. Secondly, they have good corrosion resistance, which means they can resist the corrosive effects of various chemicals and gases. Thirdly, these materials have high mechanical strength, allowing them to withstand mechanical stress and maintain their structural integrity. Additionally, chrome ore-based refractories possess high thermal conductivity, enabling efficient heat transfer. Finally, they have low thermal expansion, meaning they exhibit minimal dimensional changes when exposed to heat. These properties make chrome ore-based refractory materials ideal for use in various industrial applications, such as the lining of furnaces, kilns, and other high-temperature processing equipment.

How do refractory raw materials resist oxidation?

Refractory raw materials resist oxidation due to their high melting points and chemical composition. The materials are designed to have stable structures that can withstand high temperatures without undergoing significant chemical reactions with oxygen. Additionally, they may contain additives or coatings that provide a protective layer, preventing direct contact between the material and oxygen. This combination of factors allows refractory raw materials to maintain their integrity and resist oxidation even in harsh environments.

Wholesale Raw Materials For Refractory from supplier in Bengal

Our sales team is available to provide you with detailed information on our product range, pricing, and delivery options. We can also provide technical support and assist you in selecting the most suitable raw materials for your refractory products. Whether you need assistance with product selection, troubleshooting, or optimizing your production process, our team is here to help.

As an affiliate of CNBM, we have access to a vast network of resources and expertise. This allows us to stay at the forefront of the industry and ensure that we offer the latest and highest quality raw materials for refractory applications. We are dedicated to continuous improvement and innovation, and we constantly evaluate and update our product range to meet the evolving needs of our customers.

At our company, customer satisfaction is our top priority. We strive to build long-term partnerships with our clients by delivering exceptional products and services. We understand that each project is unique, and we work closely with our clients to provide tailored solutions that meet their specific requirements. Our team is responsive, reliable, and committed to meeting deadlines and exceeding expectations.

Contact us today to discuss your raw materials needs for refractory products in Bengal. We look forward to working with you and contributing to the success of your projects.

As an affiliate of CNBM, we have access to a vast network of resources and expertise. This allows us to stay at the forefront of the industry and ensure that we offer the latest and highest quality raw materials for refractory applications. We are dedicated to continuous improvement and innovation, and we constantly evaluate and update our product range to meet the evolving needs of our customers.

At our company, customer satisfaction is our top priority. We strive to build long-term partnerships with our clients by delivering exceptional products and services. We understand that each project is unique, and we work closely with our clients to provide tailored solutions that meet their specific requirements. Our team is responsive, reliable, and committed to meeting deadlines and exceeding expectations.

Contact us today to discuss your raw materials needs for refractory products in Bengal. We look forward to working with you and contributing to the success of your projects.

Hot Search

- Monolithic Refractories in Afghanistan

- Ceramic Fiber Products in Jordan

- Refractory Bricks in Dominican

- Raw Materials For Refractory in Finland

- Ceramic Fiber Products in Namibia

- Monolithic Refractories in India

- Monolithic Refractories in Kazakhstan

- Raw Materials For Refractory in Switzerland

- Refractory Bricks in Moldova

- Raw Materials For Refractory in Libya