Stainless Steel Wire Basket

Stainless Steel Wire Basket Related Searches

Best Paint For Stainless Steel Blanket Insulation For Steel Buildings Primer For Galvanized Steel Foam Filter For Stainless Steel H S Code For Stainless Steel Surface Grinding Wheels For Stainless Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For BbqHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Steel Mesh Panels For SaleStainless Steel Wire Basket Supplier & Manufacturer from China

Okorder.com is a professional Stainless Steel Wire Basket supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Stainless Steel Wire Basket firm in China.Hot Products

FAQ

- The different types of stainless steel wire ropes commonly used in sports equipment include 1x19, 7x7, and 7x19 constructions. These wire ropes vary in terms of their flexibility, strength, and resistance to corrosion, making them suitable for different applications in sports equipment such as cables for gym equipment, suspension systems for aerial sports, and safety harnesses for climbing.

- There are various types of stainless steel wire springs used in the automotive industry, including compression springs, extension springs, torsion springs, and coil springs. These springs are essential components in automotive applications, providing stability, support, and flexibility for various mechanical systems such as suspension, brakes, engines, and seats.

- Stainless steel wire is commonly used in the chemical industry for various applications such as filtration, separation, and reinforcement due to its excellent corrosion resistance, high temperature resistance, and strength. It is often utilized for manufacturing chemical tanks, pipelines, and storage containers, as well as for constructing filters, screens, and sieves to remove impurities or separate different substances. Additionally, stainless steel wire can be employed as reinforcing material in concrete structures, ensuring durability and longevity in chemical processing facilities.

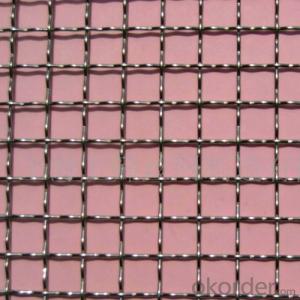

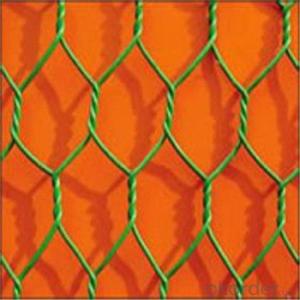

- Stainless steel wire screens are commonly used for pest control due to their durability, flexibility, and ability to withstand harsh environmental conditions. These screens are designed to prevent the entry of pests, such as insects and rodents, into buildings or specific areas. The screens are often installed on doors, windows, vents, and other openings to create a physical barrier that pests cannot penetrate. This helps to keep pests out while allowing proper ventilation and natural light to enter, ensuring a comfortable living or working environment. Stainless steel wire screens have extremely small mesh openings, which make it difficult for pests to squeeze through. The fine mesh also prevents the entry of smaller insects like mosquitoes, flies, and gnats, which are not only annoying but can also pose health risks. Moreover, stainless steel is resistant to corrosion, rust, and damage caused by weather or UV exposure. This makes the screens long-lasting, even in outdoor or high-moisture areas. They are also easy to clean and maintain, which contributes to their effectiveness in pest control. Additionally, stainless steel wire screens are environmentally friendly compared to other pest control methods that involve chemicals or pesticides. By physically blocking pests from entering, these screens minimize the need for using harmful chemicals, ultimately promoting a safer and healthier environment for humans and pets. Overall, stainless steel wire screens are a reliable and sustainable solution for pest control as they offer a robust barrier against pests without compromising on the functionality or aesthetics of the space they are installed in.

- There are several types of stainless steel wire used in conveyor belts, including 304 stainless steel, 316 stainless steel, and 430 stainless steel. These different types of stainless steel offer varying levels of corrosion resistance, strength, and heat resistance, allowing conveyor belts to be customized for specific applications and environments.

- Yes, stainless steel wire can be used for strengthening concrete. Stainless steel wire is highly resistant to corrosion, making it a suitable material for reinforcing concrete structures that are exposed to harsh environments or corrosive substances. Its high tensile strength allows it to effectively resist the forces that act on the concrete, helping to prevent cracks and increase the overall durability of the structure. Stainless steel wire can be used in various forms, such as bars, mesh, or fibers, depending on the specific requirements of the project.

- There are several different types of stainless steel wire rope terminations, including swaged fittings, hand-crimped fittings, mechanical fittings, and wire rope clips. Swaged fittings involve compressing the wire rope using a hydraulic press to create a permanent termination. Hand-crimped fittings involve manually crimping the wire rope using a crimping tool. Mechanical fittings use a combination of mechanical devices, such as screws or bolts, to secure the wire rope. Wire rope clips involve using a U-bolt and saddle to clamp the wire rope together.

- No, stainless steel wire cannot be used for wire rope lubrication. Stainless steel wire is a type of wire that is known for its corrosion resistance and durability, and it is commonly used in various applications such as construction, automotive, and electrical industries. Wire rope lubrication, on the other hand, refers to the process of applying lubricants to wire ropes to reduce friction, prevent wear and tear, and enhance the overall performance and lifespan of the rope. Lubrication is crucial for wire ropes, especially those used in heavy-duty applications such as cranes, elevators, and suspension bridges. For wire rope lubrication, specialized lubricants are used that are specifically designed to withstand the high loads and pressures that wire ropes experience during operation. These lubricants are typically oil-based or grease-based and are formulated to provide excellent adhesion and penetration into the wire rope strands. Using stainless steel wire for wire rope lubrication would not provide the necessary lubrication properties required for optimal performance and protection of the wire rope. It is essential to use appropriate lubricants that are specifically designed for wire rope applications to ensure proper lubrication and maintenance of the rope.