Carbon Welding Electrode /Titanium Welding

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Carbon Welding Electrode /Titanium Welding

Quick Information for Carbon Welding Electrode:

Class: ER1100

AWS: A5.10

Conforms to Certification: AWS A5.10 ASME SFA A5.10

Weld Process: Tig (GTAW)

Specifiaction of Carbon Welding Electrode:

AWS Chemical Composition Requirements | |

Cu = 0.05 – 0.20 | Al = 99.0 min |

Mn = 0.05 max | Si + Fe = 0.95 max |

Zn = 0.10 max | Be = 0.0003 max |

Other = 0.05 each – 0.15 total | |

Available Sizes:

Upon Request, call for more information

Characteristics of Carbon Welding Electrode:

Type ER1100 can be used to weld base materials types 1060, 1070, 1080, and 3003.

Welding Filler Wire

Heat Exchangers

Food Handling Equipment

Rivets

Main Features of Carbon Welding Eletrode:

The proper choice of aluminum filler metal mainly depends on the base metal properties to be achieved and welding technique. Post weld cracking, corrosion resistance and behavior under elevated temperature also need to be taken into consideration. Cracking usually can be minimized by choosing a filler metal alloy of higher alloy content then the base metal.

Deposited Chemical Composition % (Typical)

Deposited chemistry is influenced by many factors so no typical analysis can be reported.

Deposited All Weld Metal Properties %

As-Welded

Deposited all weld metal properties are influenced by many factors such as weld process used, so no typical weld metal properties can be reported.

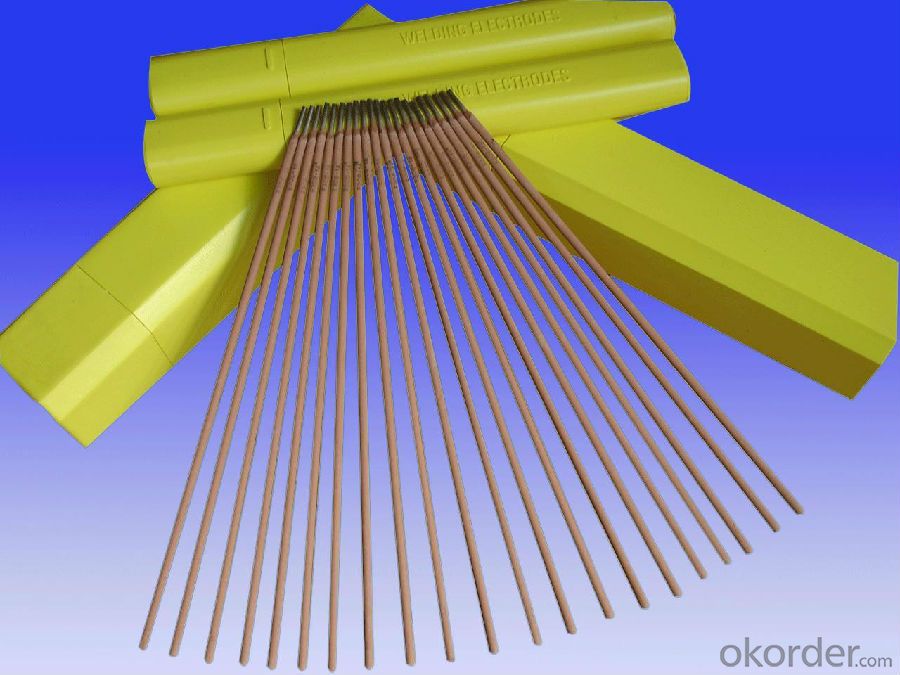

Pictures:

- Q:Is stainless steel wire suitable for architectural applications?

- Yes, stainless steel wire is highly suitable for architectural applications. It is known for its exceptional strength, durability, and corrosion resistance, making it ideal for use in architectural structures, such as handrails, balustrades, facades, and decorative elements. Additionally, stainless steel wire offers a sleek and modern aesthetic, enhancing the overall appearance of architectural designs.

- Q:What are the different types of stainless steel wire ropes for rigging?

- For rigging purposes, there exists a variety of stainless steel wire ropes. These ropes differ in their construction, strength, and resistance to corrosion. Here are some of the most commonly used types: 1. 1x19 Construction: This wire rope is formed by twisting together 19 individual strands, creating a singular strand. It offers high tensile strength and minimal stretch, making it perfect for applications that necessitate a rigid and inflexible wire rope. 2. 7x7 Construction: Composed of 7 strands, each consisting of 7 wires twisted together, this wire rope provides good flexibility. It is commonly employed for light-duty applications like marine rigging or control cables. 3. 7x19 Construction: Similar to the 7x7 construction, this wire rope also consists of 7 strands. However, each strand is made up of 19 wires twisted together. It offers improved flexibility compared to the 7x7 construction and is commonly used for general-purpose rigging, such as in winches or hoists. 4. 6x19 Construction: This wire rope comprises 6 strands, with each strand composed of 19 wires twisted together. It provides a favorable combination of flexibility and strength, making it suitable for a wide range of applications, including cranes, elevators, and suspension bridges. 5. 6x36 Construction: Made up of 6 strands, with each strand consisting of 36 wires twisted together, this wire rope offers high flexibility. Additionally, it has a greater resistance to bending fatigue, making it ideal for applications that require repeated bending or flexing, such as cable-laid slings or winch lines. 6. 6x37 Construction: Similar to the 6x36 construction, this wire rope also has 6 strands. However, each strand is made up of 37 wires twisted together. It provides even greater flexibility and is commonly used in applications that necessitate heavy-duty lifting, towing, or mining. It is crucial to consider the specific requirements of your rigging application and seek professional advice to determine the most suitable type of stainless steel wire rope to utilize.

- Q:Can stainless steel wire be used in high-temperature applications?

- Yes, stainless steel wire can be used in high-temperature applications. Stainless steel is known for its excellent heat resistance and can withstand elevated temperatures without losing its strength or corrosion resistance. It is commonly used in industries such as aerospace, automotive, and manufacturing where high temperatures are encountered.

- Q:What is drawing stainless steel, with ordinary light stainless steel what is the difference?

- Stainless steel, corrosion resistance of stainless steel with increased carbon content decreased, therefore, the carbon content of most stainless steel are relatively low, the maximum of no more than 1.2%, some steel Wc (carbon) or even less than 0.03% (such as 00Cr12). The main alloying element in stainless steel is Cr (chromium), which is corrosion resistant only when the Cr content reaches a certain value. Therefore, stainless steel in general Cr (chromium) content of at least 10.5%. Stainless steel also contains Ni, Ti, Mn, N, Nb, Mo, Si, Cu and other elements.

- Q:What are the common uses of stainless steel wire in the aerospace industry?

- Stainless steel wire is commonly used in the aerospace industry for a variety of applications. It is primarily used for structural purposes, such as reinforcing aircraft frames, manufacturing support structures, and forming cables for suspension systems. Additionally, stainless steel wire is used in the fabrication of engine components, electrical wiring, and fuel line systems due to its high strength, corrosion resistance, and excellent heat resistance properties.

- Q:What are the main characteristics of stainless steel wire?

- Stainless steel wire is known for its unique set of characteristics that make it a popular choice in various industries. Firstly, stainless steel wire is highly resistant to corrosion. This is due to the presence of chromium in its composition, which forms a protective oxide layer on the surface of the wire, preventing it from rusting or tarnishing. This attribute makes stainless steel wire suitable for outdoor applications or in environments where it may be exposed to moisture or corrosive substances. Secondly, stainless steel wire is known for its strength and durability. It has a high tensile strength, meaning it can withstand heavy loads and resist deformation. This makes it suitable for applications that require a strong and reliable material, such as in construction, automotive, or aerospace industries. Another important characteristic of stainless steel wire is its versatility. It can be easily fabricated into various shapes and forms, allowing for a wide range of applications. Whether it is woven into mesh for filtration purposes, used as a reinforcement in concrete, or formed into springs for mechanical components, stainless steel wire can be adapted to meet specific requirements. Furthermore, stainless steel wire has excellent heat resistance. It can withstand high temperatures without losing its strength or becoming brittle. This property makes it suitable for applications that involve exposure to heat, such as in the manufacturing of cooking utensils, heat exchangers, or industrial ovens. Lastly, stainless steel wire is known for its aesthetic appeal. It has a smooth and reflective surface that gives it a polished and professional look. This makes it a popular choice for architectural applications, decorative purposes, or even in the jewelry industry. Overall, the main characteristics of stainless steel wire include corrosion resistance, strength, versatility, heat resistance, and aesthetic appeal. These properties make it a reliable and sought-after material in various industries where durability, performance, and appearance are essential.

- Q:What are the different types of stainless steel wire sleeves?

- There are several different types of stainless steel wire sleeves available, each designed to serve specific purposes and applications. 1. Standard Stainless Steel Wire Sleeves: These sleeves are made from corrosion-resistant stainless steel and are commonly used for general-purpose wire protection. They provide excellent abrasion resistance and can withstand high temperatures, making them suitable for various industries such as automotive, aerospace, and electronics. 2. Mesh Stainless Steel Wire Sleeves: These sleeves are constructed with a woven mesh design that allows for flexibility and breathability. They are commonly used in applications where wire protection is required while also allowing for ventilation or fluid flow. Mesh sleeves are often used in industries such as HVAC, industrial machinery, and marine. 3. Heavy-Duty Stainless Steel Wire Sleeves: These sleeves are specifically designed to provide maximum protection for wires and cables in rugged and demanding environments. They are made from thicker stainless steel materials and offer superior resistance to impact, abrasion, and extreme temperatures. Heavy-duty sleeves are commonly used in industries such as mining, construction, and oil and gas. 4. Coated Stainless Steel Wire Sleeves: These sleeves have a protective coating applied over the stainless steel material, providing additional resistance to chemicals, moisture, and UV radiation. The coating can be made of materials such as PVC, Teflon, or silicone, depending on the specific application requirements. Coated sleeves are often used in industries such as automotive, telecommunications, and electrical. 5. Expandable Stainless Steel Wire Sleeves: These sleeves are designed with an expandable structure that allows for easy installation and removal without the need for disassembling the wires or cables. They provide a flexible and adjustable solution for wire protection in applications where frequent maintenance or changes are required. Expandable sleeves are commonly used in industries such as robotics, automation, and telecommunications. Overall, the different types of stainless steel wire sleeves offer a range of options to meet specific wire protection needs, ensuring durability, corrosion resistance, and functionality in various industries and applications.

- Q:What is the minimum diameter of stainless steel wire? Do you have a price smaller than 10 microns? Where can I sell it?

- Industrial grade stainless steel wire can only reach 0.05mm, if you want to reach 10 microns, I'm afraid you have to find a special custom manufacturers. Good luck!

- Q:Can stainless steel wire be used for springs in the oil and gas industry?

- Yes, stainless steel wire can be used for springs in the oil and gas industry. Stainless steel is known for its excellent corrosion resistance, mechanical properties, and high tensile strength, making it a suitable material for demanding environments such as the oil and gas industry. Stainless steel springs can withstand high temperatures, pressure, and exposure to various chemicals and corrosive substances commonly found in this industry. Additionally, stainless steel's durability and longevity make it a reliable choice for springs that require long service life and minimal maintenance.

- Q:Can stainless steel wire be used for jewelry findings?

- Yes, stainless steel wire can be used for jewelry findings. Stainless steel is a durable and corrosion-resistant material commonly used in jewelry making. It is often used for making findings such as clasps, jump rings, and ear wires due to its strength and stability.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Welding Electrode /Titanium Welding

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords