Carbon Steel Welding Wires Electrodes Carbon

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

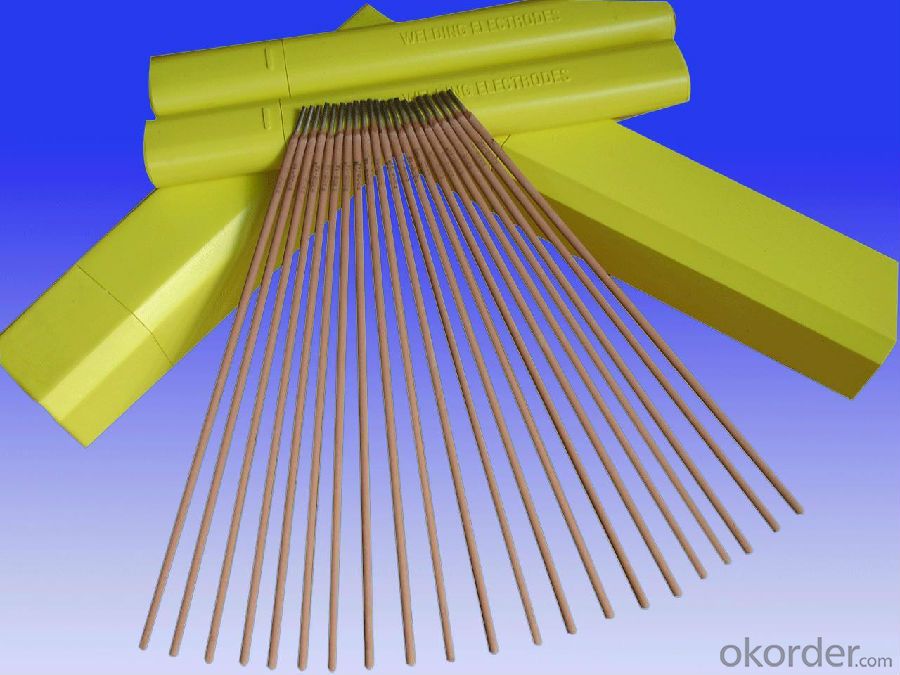

Structure of Carbon Steel Welding Wire Electrodes

1) Specially for Vertical-down welding

2) Perfect welding performance.

3)Operating current: 2.5MM:30-50,32.MM:70-100,4.0MM:90-140, 5.0MM: 150-200

4)Diameter:2.5mm-5.0mm

5)Material:Carbon Steel

6)Length:300-400mm

7)Delivery Time: 15-30 days after receiving L/C or pre-paid

Main Feature of Carbon Steel Welding Wire Electorde

Detail Package:All products will be standard export package, will be wooden boxes or bundled by steel strips, or as per customer's requirement

steel wire is a high cellulose potassium type welding rod for mild steel.

It is suitable for vertical -down welding and lap welding for sheet structures.

Such as smoke pipes, wind pipes ,oil tanks of teansformer, outside cover of vehicles.

FAQ

Why should you choose us?

Chose happens because of quality, then price, we can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents),

Quick goods delivery, our factories locate near the seaport, which is very convenient for transportation.

Datas Information of Carbon Steel Welding Wire Electorde

Chemical Composition of Deposited Metal(%)

| C | Mn | Si | S | p | Ni | Cr | Mo | V |

| ≤0.2 | ≤1.2 | ≤1.0 | ≤0.035 | ≤0.040 | ≤0.3 | ≤0.2 | ≤0.3 | less than 0.08 |

Pictures:

- Q:What are the tensile strength and yield strength of stainless steel wire?

- The tensile strength and yield strength of stainless steel wire can vary depending on the specific grade or alloy of stainless steel being used. Generally, stainless steel wire has a high tensile strength, typically ranging from 500 to 2000 megapascals (MPa), or 72,500 to 290,000 pounds per square inch (psi). This high tensile strength allows stainless steel wire to withstand significant pulling or stretching forces without breaking. On the other hand, the yield strength of stainless steel wire refers to the point at which it begins to deform permanently when subjected to a specific amount of stress. This is usually lower than its ultimate tensile strength. The yield strength of stainless steel wire can range from 200 to 1500 MPa (29,000 to 217,500 psi). It's important to note that the tensile strength and yield strength of stainless steel wire can be further influenced by factors such as the manufacturing process, heat treatment, and the specific alloy composition. Therefore, it is essential to refer to the technical specifications or consult with manufacturers or suppliers to obtain accurate and specific information regarding the tensile and yield strength of a particular stainless steel wire.

- Q:Fracture analysis of stainless steel screw

- Stainless steel screws used in the quality of raw materials, stainless steel screws, wire quality is not good. There are a lot of impurities, impurities, leading to stainless steel screw hardness is not enough.

- Q:Can stainless steel wire be used for springs in the manufacturing industry?

- Yes, stainless steel wire can be used for springs in the manufacturing industry. Stainless steel is a strong and durable material with excellent corrosion resistance, making it an ideal choice for springs that need to withstand heavy loads or operate in harsh environments. Its high tensile strength ensures that the springs can retain their shape and provide the necessary elasticity for various applications. Additionally, stainless steel springs are often preferred due to their resistance to rust and staining, making them suitable for use in industries such as automotive, aerospace, and medical, where reliability and longevity are crucial.

- Q:Stainless steel wire drawing plate, matte stainless steel is the same

- Oil is brushed stainless steel cold rolling (2B/BA surface), by grinding unit (steel coil) after processing the metal surface, due to the use of rolling oil cooling in the grinding process, commonly known as oil scrub, by abrasive belt surface NO.3/NO.4 (usually short hair lines) and HL (drawing filament hairline). After the polishing unit (plate grinding machine), the rear surface usually has a 8K surface (mirror panel), such as surface coating, etching and other treatment, will be different surfaces and patterns, to meet the needs of different users. These are surface treatment of cold-rolled finished products for obtaining different stainless steel surfaces. Any dirt will be attached to the surface of Wat, stainless steel products after processing any surface is no exception. If not easy to adhere to dirt, usually surface coating treatment (such as anti fingerprint processing, etc.), easy to clean.

- Q:What are the different wire gauges available for stainless steel wire?

- Different applications and requirements can be met with a variety of sizes for stainless steel wire gauges. The most commonly used wire gauges for stainless steel wire are usually measured in American Wire Gauge (AWG) or Standard Wire Gauge (SWG). In the United States, AWG is the most widely used measurement system, where the gauge number increases as the wire diameter decreases. AWG stainless steel wire gauges typically range from 10 to 38, with 10 being the thickest and 38 being the thinnest. These gauges find common use in electrical wiring, jewelry making, and industrial applications. On the other hand, SWG is a British measurement system also utilized in some parts of the world, including the United Kingdom. In SWG, as the gauge number increases, the wire diameter also increases. SWG stainless steel wire gauges range from 1 to 46, with 1 being the thickest and 46 being the thinnest. These gauges are commonly employed in various applications such as fencing, mesh manufacturing, and cable production. It is important to note that the specific stainless steel wire gauges available may vary depending on the supplier or manufacturer. To ensure the appropriate gauge selection for your specific needs, it is advisable to consult with the supplier or refer to standardized wire gauge charts.

- Q:What are the different wire forming techniques used for stainless steel wire?

- There are several wire forming techniques used for stainless steel wire, including drawing, rolling, and bending. Drawing involves pulling the wire through a die to reduce its diameter and increase its length. Rolling involves passing the wire between two or more rotating rollers to shape it into a desired form. Bending is used to create specific angles or curves in the wire by applying pressure or heat. These techniques allow for the creation of various stainless steel wire products for different applications.

- Q:Is stainless steel wire suitable for jewelry findings?

- Indeed, jewelry findings can be made using stainless steel wire. Stainless steel wire is an incredibly robust and enduring material, capable of resisting tarnish, corrosion, and rust. Its exceptional strength and stability render it perfect for a wide range of jewelry findings, including clasps, jump rings, ear wires, and chain links. Moreover, individuals with metal allergies or sensitive skin will find stainless steel wire to be hypoallergenic. Furthermore, its polished and sleek appearance imparts a contemporary and refined aesthetic to jewelry designs.

- Q:What are the different surface finishes available for stainless steel wire?

- Stainless steel wire offers a range of surface finishes, each with its own purpose and visual appeal. Here are some of the most popular options: 1. The standard finish for stainless steel wire is the bright finish, also referred to as a mill finish. It boasts a smooth and shiny appearance, making it suitable for general applications where aesthetics aren't a top priority. 2. Another option is the matte finish, which has a non-reflective and dull look. Achieved by brushing the wire surface, this finish is ideal for architectural and decorative purposes where minimizing glare and reflection is essential. 3. The mirror finish, as its name implies, produces a highly reflective surface akin to a mirror. This glossy appearance is achieved by polishing the wire with fine abrasives, making it a popular choice for high-end applications like jewelry or automotive parts. 4. Stainless steel wire can also be coated with different materials to enhance its performance or appearance. For instance, a polymer coating can improve corrosion resistance or provide electrical insulation. Other coatings, such as PTFE or nylon, can reduce friction or introduce specific colors. 5. Passivation, a chemical process, is used to eliminate surface contaminants and enhance the corrosion resistance of stainless steel wire. This passivated finish is commonly employed in applications exposed to harsh environments or corrosive substances. It's important to note that the availability of these surface finishes may vary depending on the specific grade and thickness of the stainless steel wire. Therefore, it is advisable to consult a supplier or manufacturer to ensure the desired finish is available for your specific application.

- Q:Does stainless steel wire have any health benefits?

- No direct health benefits are associated with stainless steel wire. The main advantage of stainless steel lies in its durability, strength, and resistance to corrosion, making it highly sought after in industries like construction, automotive, and manufacturing. Although stainless steel wire can be utilized in medical devices such as surgical instruments and orthopedic implants, its health benefits stem from the functionality and performance of these devices, rather than the wire itself. When used in isolation, stainless steel wire does not possess any inherent properties that promote health or well-being.

- Q:Which is better, such as stainless steel wire drawing board and rose gold drawing board, such as moisture-proof effect, abrasion resistance and so on?

- Stainless steel surface is like filamentous texture, this is only a stainless steel processing technology. The surface is Matt, and carefully look at the above there is a trace of texture, but can not touch it.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Steel Welding Wires Electrodes Carbon

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords