Bx1200 Geogrid Specification

Bx1200 Geogrid Specification Related Searches

Biaxial Plastic Geogrid Geogrid Grass Pp Biaxial Geogrid Tx-5 Geogrid Multi Plastics Extrusion Polypropylene Biaxial Geogrid Bx1200 Geogrid Specification Biaxial Integral Geogrid Biaxial Geogrid Bx1200 Geogrid GravelHot Searches

Fiberglass Scaffolding For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale Geogrid Fabric For Sale Gas Powered Core Aerator For Sale Revolution 4 Propeller For Sale Alabaster Carving Stone For Sale Geogrid For Sale Near Me Tensar Geogrid For Sale Geogrid For Sale Ex Display Log Cabins For Sale Photoelectric Cells For Sale Athletic Lockers For Sale Cubicle Partitions For Sale Stearman Propeller For Sale Palram Greenhouses For Sale Gumbo Bowls For Sale Suzuki Propellers For Sale Freight Crates For Sale Outhouse Sheds For SaleBx1200 Geogrid Specification Supplier & Manufacturer from China

Okorder.com is a professional Bx1200 Geogrid Specification supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Bx1200 Geogrid Specification firm in China.Hot Products

FAQ

- The dam is protection of geomembrane or gabion.

- The protective effect is good, and the soil erosion is prevented

- Yes, geogrids can be used in landfill liners. They are often used as part of a composite liner system to enhance the stability and performance of landfill liners. Geogrids provide reinforcement and improve the tensile strength of the liner, helping to prevent soil erosion and enhance the overall integrity of the landfill liner system.

- Where the geogrid is the cheapest! Plastic fiber polyester fiberglass geogrid there?

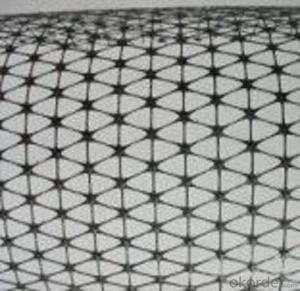

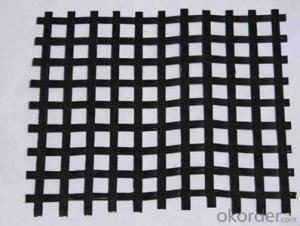

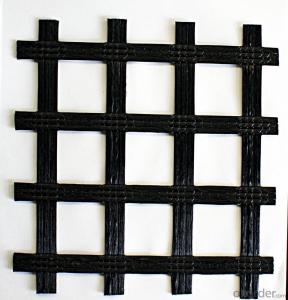

- The geogrid grille is made of polypropylene, PVC polymer and thermoplastic or molded by two-dimensional grid or a certain height of the three-dimensional mesh screen, when used as a civil engineering, called geogrid.

- Some cost considerations for using geogrids in construction projects include the initial purchase cost of the geogrid material, the installation cost, and the potential long-term cost savings due to increased stability and durability of the construction. Additionally, the cost of maintenance and repairs may be reduced as geogrids can help prevent soil movement and erosion.

- Yes, there are specific requirements for geogrid installation in road construction. These requirements include properly preparing the subgrade, ensuring proper tensioning and alignment of the geogrid, using appropriate anchoring and connection methods, and conducting regular inspections to ensure the geogrid remains in place and functions effectively. Additionally, the geogrid should be installed according to the manufacturer's recommendations and in compliance with industry standards and specifications.

- Geogrids have excellent long-term durability characteristics. They are typically made from high-strength materials such as polyester or polypropylene, which are resistant to degradation caused by UV exposure, chemical exposure, and biological factors. Geogrids also have high tensile strength, allowing them to withstand heavy loads and maintain their structural integrity over time. Additionally, they have low creep and deformation rates, meaning they can maintain their original shape and performance for an extended period. Overall, geogrids have proven to be highly durable and reliable for various applications in civil engineering and construction.

- Geogrids prevent lateral spreading of soil by providing reinforcement and stabilization to the soil layers. They are made of high-strength materials and are placed within the soil, creating a network of interconnected elements. This network enhances the soil's shear strength and restricts its movement, preventing lateral spreading. Additionally, geogrids distribute the applied loads more evenly, reducing the stress on the soil and minimizing the potential for soil movement.

- The factors that affect the cost-effectiveness of geogrids include the quality and strength of the geogrid material, the size and complexity of the project, the type of soil being reinforced, the installation method, and the long-term performance and durability of the geogrid. Additionally, factors such as transportation and logistics costs, project timeline, and the availability of alternative solutions can also influence the overall cost-effectiveness of geogrids.