PP Biaxial Geogrid with High Tensile Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specification---PP Biaxial Geogrid

Introduction:

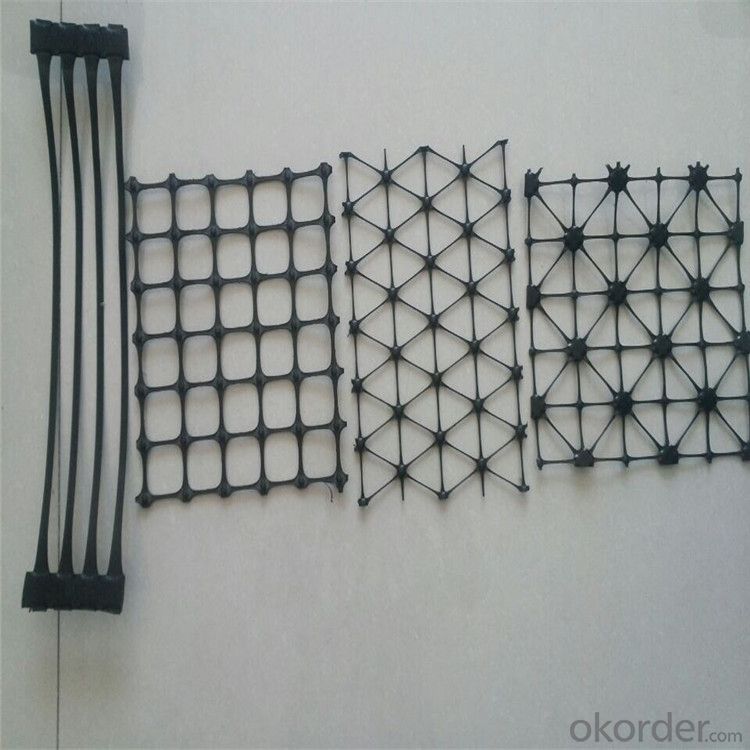

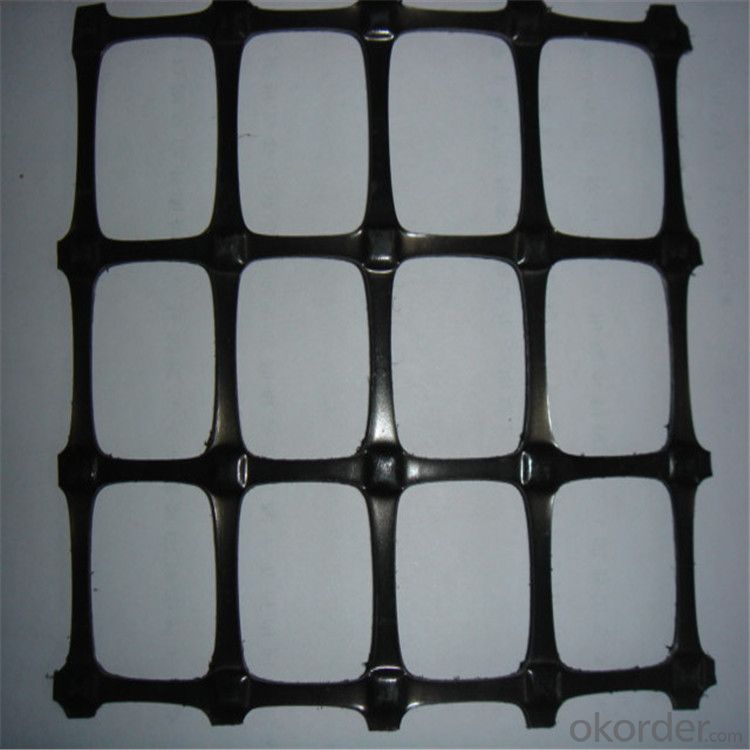

Biaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern, and finally stretched in longitudinal and transverse directions.

Features:

1. With high tensile strength in longitudinal and transverse directions

2.This structure can provide an chain system of more effective force bearing and spreading for the soil.

Application:

Mainly applied in highway, railway, slope protecting projects etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ;

reducing project cost and maintenance cost.

Properties of PP Biaxial Geogrid (Test Method: ASTM D 6637)

Item Spec | TGSG 15-15 | TGSG 20-20 | TGSG 25-25 | TGSG 30-30 | TGSG 35-35 | TGSG 40-40 | TGSG 45-45 | TGSG 50-50 | ||

Tensile Strength ≧(Kn/m) | MD | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | |

TD | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | ||

Nominal Elongation ≦(%) | MD | 15 | ||||||||

TD | 13 | |||||||||

Tensile Strength at 2% Strain ≧(Kn/m) | MD | 5 | 7 | 9 | 10.5 | 12 | 14 | 16 | 17.5 | |

TD | 5 | 7 | 9 | 10.5 | 12 | 14 | 16 | 17.5 | ||

Tensile Strength at 5% Strain ≧(Kn/m) | MD | 7 | 14 | 17 | 21 | 24 | 28 | 32 | 35 | |

TD | 7 | 14 | 17 | 21 | 24 | 28 | 32 | 35 | ||

Junction Efficiency (%) | 93 | |||||||||

Width ≦(m) | 6 | |||||||||

Note: MD: Machine direction

TD: Transverse direction

Images of PP Biaxial Geogrid

- Q:GSL50 what is the meaning of Geogrid

- GSL50 represents the longitudinal and transverse tensile strength more than 50KN of plastic geogrids.

- Q:How do geogrids improve the performance of geotextile sediment control tubes?

- Geogrids improve the performance of geotextile sediment control tubes by providing additional strength and stability to the structure. They enhance the overall integrity of the tube, preventing deformation or collapse due to external forces such as water pressure or soil movement. Geogrids also help distribute the load evenly, reducing the risk of localized failures. Overall, the inclusion of geogrids significantly enhances the effectiveness and longevity of geotextile sediment control tubes in controlling sediment and erosion.

- Q:Are geogrids resistant to chemical degradation?

- Yes, geogrids are generally resistant to chemical degradation. They are designed to withstand exposure to various chemicals commonly found in soil and water, such as acids, alkalis, and organic compounds. This chemical resistance ensures the long-term durability and performance of geogrids in different environmental conditions.

- Q:What are the factors that affect the long-term performance of geogrids?

- There are several factors that can influence the long-term performance of geogrids. These include the type and quality of materials used in the manufacturing of the geogrid, the installation process and techniques employed, the environmental conditions to which the geogrid is exposed, and the level of maintenance and monitoring provided. Additionally, factors such as load characteristics, soil properties, and the design and construction of the overall geotechnical system can also impact the long-term performance of geogrids.

- Q:Classification of plastic geogrid

- First, what is a one-way plastic geogrid: one-way plastic geogrid is a high density polyethylene (HDPE) as raw material, through the extrusion press into a thin plate and then the rules of the hole network, and then the longitudinal tensile geogrid.Two, what are the characteristics of one-way plastic geogrid:1, the polymer into a linear state and the formation of a uniform distribution, high strength of the node of the long elliptical mesh integral structure. This kind of structure has high tensile strength and rigidity, and it provides the ideal chain system of bearing and diffusion of soil.

- Q:Are geogrids suitable for coastal engineering projects?

- Yes, geogrids are suitable for coastal engineering projects. They are commonly used to reinforce and stabilize coastal structures such as seawalls, breakwaters, and revetments. Geogrids provide excellent soil reinforcement, preventing erosion and enhancing the stability of coastal structures in the face of wave action and tidal forces. Furthermore, their high tensile strength and durability make them ideal for withstanding the harsh marine environment.

- Q:How do geogrids improve the performance of geogrid-reinforced earth walls?

- Geogrids improve the performance of geogrid-reinforced earth walls by providing reinforcement and stability to the soil. They distribute the loads applied to the wall more evenly, reducing the risk of wall failure and enhancing its overall strength. Additionally, geogrids increase the friction between soil particles, preventing soil movement and improving the wall's resistance to lateral pressures.

- Q:What are the design considerations for geogrid reinforcement?

- Some design considerations for geogrid reinforcement include the type and strength of the geogrid material, the required level of soil stabilization, the anticipated loads and stresses on the reinforced soil structure, and the desired lifespan of the structure. Other factors to consider include soil characteristics, installation and construction procedures, and environmental conditions. Additionally, the design should account for factors such as slope stability, drainage, and potential settlement.

- Q:I am a site using two-way 80 plastic geogrid, the need to use U type nails specifications and prices? Consultation with the construction process, thank you.Correction: two-way 80 steel plastic geogrid.

- Base leveling and laying geogridAfter the impact and compaction of the foundation, the flat base machine is used to flatten the uneven base after impact, so as to meet the requirements of the smoothness of the geogrid. And then use the iron three wheel roller for the foundation of the light roller, after testing to meet the requirements of the construction work of geogrid. Laying process and quality to meet the requirements of design and specification.

- Q:How do geogrids improve the bearing capacity of foundations?

- Geogrids improve the bearing capacity of foundations by increasing soil stability and reinforcement. They act as a mesh or lattice-like structure that is placed within the soil, distributing the load more evenly and preventing soil from shifting or settling. This helps to reduce settlement and improve the overall strength and stability of the foundation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PP Biaxial Geogrid with High Tensile Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords