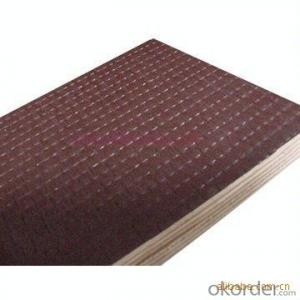

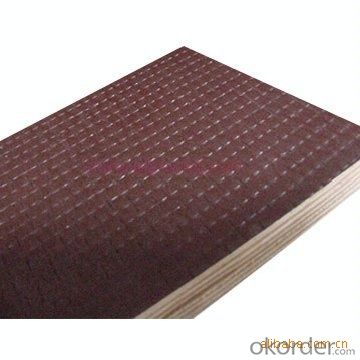

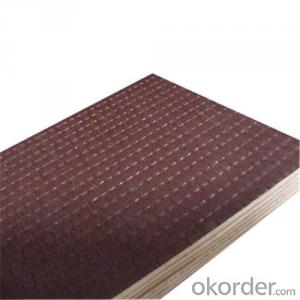

Square Design Anti-Slippery Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Description:

Square Design Antil-Slippery Film Faced Plywood are widely used in construction repeatly.

Characters:

Light, easy to install and disassemble; be used recyclely, waterproof.

Products Details:

Name | Film faced plywood |

Material | Poplar, combi core, hardwood,brich |

Size | 1220*2440/ 1250*2500 mm,or as per your request |

Thickness | 9-25mm |

Glue | E2, E1, E0,Melamine,WBP, MR |

Density | 500-600 kgs/m3 |

Face/back | Brown, black |

MC | Below 14% |

Certificate | CARB, CE, ISO9001,ISO14001, |

Used time | More than 10 times |

Usage | Construction etc |

Detailed Specification:

Product name: Anti-Slippery Film Faced Plywood

1) Size: 1220×2440mm, 1250×2500mm,1500×3000mm,1525×3500mm, or as request

2) Thickness: 4-100mm

3) Glue: MR, Melamine,WBP Core: Poplar, Birch, Pine, Hardwood,etc

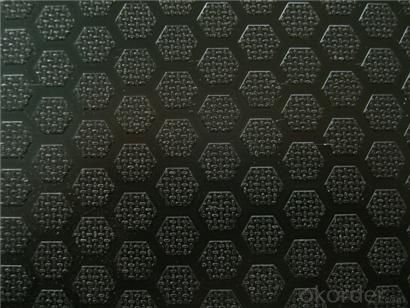

4) Surface: Imported Brown/Black Film; Chinese Brwon/Black Film

5) Anti-slip Pattern: Square

6) Special Treatment: Bevel, Tongue & Groove,Punch, etc

7) Moisture Content: 8-14%

8) Application: Concrete forming, Platform, Cassette Systems and Trailer Flooring, etc.

Package:Inter packing: 0.20mm plastic bag

Outer packing: pallets are covered with thin plywood or carton and then 4*6 steel straps for strength.

Conveyance:

20’GP:8 pallets/23m³

40’GP:16 pallets/45m³

40’HQ:18 pallets/57m³

Delivery time:

Within 15 days on receipt of deposit or original L/C

Min Order:1X40’FCL

Payment:L/C at sight, T/T(30%deposit)

Supply ability:5000 cubic meters/month

Main market: Middle east,Africa,UAE,Qatar,Oman,Russian,etc

FAQ:

Q1.What are the advantages of Anti-Slippery Film Faced Plywood?

A1:

1.No wapping, no fracture,not out of shape , it can stay 24hours in boiling water.

2.Good performance and more turnover use time.

3.It is easy to take off the membrane;Time is only 1/7 of the steel mould.

4.Make the surface of concrete more smooth and beautiful,so it can be easy to make decoration and it also deduct the processing of plastering.

5.This can moderate and contact 30% time for a project.

6.Corrosion resistant and ir will nor pollute the surface of concrete.

7.It is good to keep performance warm,ia favorable to make constrution in winter.

8.Products can be made into warping plywood

9.It is better to nail,saw,drill than bamboo and steel mould,can it can be processed into different type

- Q:Contemporary plywood market development

- as well as foreign high-quality hardwood wood constantly added for the Chinese plywood industry's continuous development To provide a wealth of raw materials; adequate human resources,

- Q:What are the advantages and disadvantages of plywood?

- the construction is convenient, not Qu Qiao, stripes tensile mechanical properties. light weight, clear lines, insulation, strength, not easy to deformation.

- Q:Distinguish between multilayer boards and plywood

- Plywood is one of the common materials for furniture, one of the three panels of man-made board, but also for aircraft, ships, trains, cars, construction and packaging materials.

- Q:Multilayer plywood with what method is fixed

- usually with odd-level veneer, and the adjacent layer of veneer Of the fibers are perpendicular to each other

- Q:Wood board, plywood, MDF What is the difference

- Blockboard thickness specifications for the 16,19,22,25 mm quality grade is divided into one, two, three three levels

- Q:Class III resistant tide plywood class IV tonic resistant plywood

- and the dashboard and the inner panel are arranged symmetrically on both sides of the center layer or the core.

- Q:What are the further processing of plywood?

- Curved plywood cutved plywood Plywood that has been bent once or several times.

- Q:Plywood is generally used in applications where the strength and stability of the material are relatively high

- . It can do the floor of the container and other buildings and factories that need to be gravitational, and can be used as a scaffolding. Liquefied gas transport isolation box and so on.

- Q:Does plywood contain formaldehyde?

- 12 cm plywood is usually 3-4 layers of natural wood chips "glue" together, each layer of double-sided roller plastic hot forming, the whole board about 3 kg of glue

- Q:What are the defects in plywood material?

- Fracture split, end split The fiber is separated in the direction of the grain, usually starting from one end and extending through the thickness of the morning plate

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Square Design Anti-Slippery Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords