AA1070 D.C Mill Finished Aluminum Circles used for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

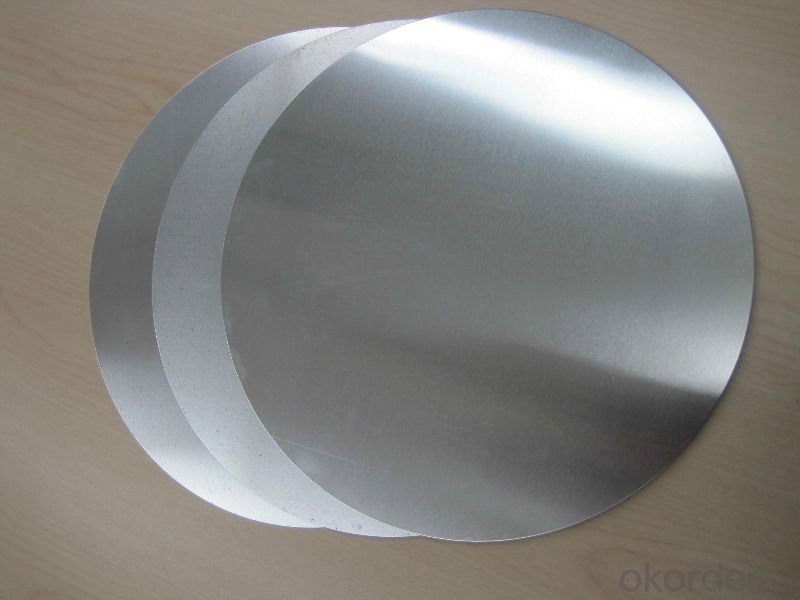

1.Structure of AA1070 D.C Mill Finished Aluminum Circles used for Cookware Description

AA1070 D.C Mill Finished Aluminum Circles used for Cookware is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

AA1070 D.C Mill Finished Aluminum Circles used for Cookware is one semi-finished aluminium material. This strip can be rolled down to aluminium foil.The final thickess can be 5-20 microns. Aluminium foil is soft, ductile and with a silver-white luster which can be widely used in a large scare of fields.

2.Main Features of AA1070 D.C Mill Finished Aluminum Circles used for Cookware

1)Surface Quality : be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks,

2)Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

3)Fine craftsmanship

4)Durable

5)Easy processing

3.AA1070 D.C Mill Finished Aluminum Circles used for Cookware Images

4.AA1070 D.C Mill Finished Aluminum Circles used for Cookware Specification

Alloy | AA1070 |

Temper | H14, H16, H18,O/F |

Thickness | 0.5mm -- 4mm |

Diameter | 200mm -- 1200mm |

Standard | GB/T 3880-2006 |

5. FAQ of AA1070 D.C Mill Finished Aluminum Circles used for Cookware

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

- Q:What are the differences between aluminum bars 5052 and 6063?

- 5052 aluminum alloy density: 2.68g/cm3; 6063 aluminum alloy density: 2.71g/cm3. aluminum alloy casting and extrusion form density is different, extrusion aluminum alloy density is higher.

- Q:In cutting aluminum rods, the teeth of the disc saw are occasionally knocked out. How can they be avoided?

- The forward (feed) speed is a little slower to avoid.

- Q:Influence of cooling water temperature on surface segregation layer of aluminum rod

- Why not shiny aluminum rod: rust generated three two aluminum oxide (Al2O3) removal method: three oxidation reaction of two aluminum material with 1 examples: sodium hydroxide (NaOH) 1, three two aluminum oxide and sodium hydroxide, aluminum hydroxide, aluminum hydroxide 2 generation 3 heating decomposition

- Q:6061 aluminum bars have spots after turning. Is it the problem of raw material?

- I've met this situation! Cutting oil doesn't work. For clean cutting oils, it is better to use copper cutting oils.

- Q:Why would the stick saw be cut in the aluminum bar?

- Welcome to consult Feng rui1 tool, Feng rui1 was happy to answer for you.

- Q:4.2 of drill bit, drill bit, old broken... Material (aluminum bar).. please help me, how to do it will do well

- Lathe or drilling machine, with coolant, it should be very good, ah, more than a few back.

- Q:How much should the speed of the 20mm aluminum bar and the wire speed be cut off by the 2mm mechanical cutting machine of the NC machine?

- Speed is about 500r, line speed 5m/s on the line, feed speed election 0.1mm/r, I hope useful for you, ha ha!

- Q:Aluminum stick, 6351-t6? What do you mean?

- T6 refers to heat treatment process. The state of artificial ageing after T6 solution heat treatment is applicable to the products which are no longer subjected to cold working after the solid solution heat treatment (can be straightened and leveling, but does not affect the mechanical performance limit).

- Q:the bore is 23, how to process the inside hole ah, where to process ah, 15Like the mirror surface of the cylinder, I know how to drill, but how to smooth out the smooth surface. What mechanical process is necessary? Thank you!

- Can inner circle grinder for grinding internal hole, no conventional grinding wheel, polishing wheel, the kind of cotton

- Q:What does aluminium bar 5052 mean?

- Three, 5052-, H34 aluminum chemical composition:Aluminum Al: margin; silicon Si:0.25;Copper Cu:0.10; magnesium Mg:2.2 ~ 2.8;Zinc Zn:0.10; manganese Mn:0.10;Chromium Cr:0.15 ~ 0.35; iron Fe:0.4 0.Mechanical properties of four, 5052-, H34 aluminum plateTensile strength B MPa (170~305)Conditional yield strength (MPa = 65) 0.2Modulus of elasticity: E 69.3 ~ 70.7GpaThe annealing temperature is 345 DEG C.Surface quality of five, 5052- H34 aluminium plate1, the surface does not allow cracks, corrosion spots and trace nitrate.2, on the surface is allowed to have a depth of no more than the defect location of wall thickness of nominal size 8% peeling, bubble, surface rough and local mechanical damage, but the defects of the maximum depth of not more than 0.5mm, the total defect area of not more than 5% of the total area of the plate.3, allow the supplier to polish the smooth surface along the longitudinal profile.4 other requirements: the demand side and the supplier to develop their own.Six, 5052-, H34 aluminum welding electrode model5052 aluminum plate can be welded with ER5356 welding rod. After welding, the mechanical properties of the 5052 aluminum sheets can be met. 5356 of the chemical composition: Si:0.25; Fe:0.40; Cu:0.10; Mn:0.05-0.20; Mg:4.5-5.6; Cu:0.02--0.20; Zn:0.10- 0.20; Ti:0.06--0.20; Al: margin; 5336 higher magnesium content.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AA1070 D.C Mill Finished Aluminum Circles used for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches