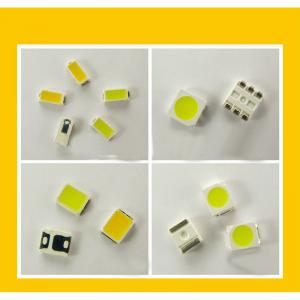

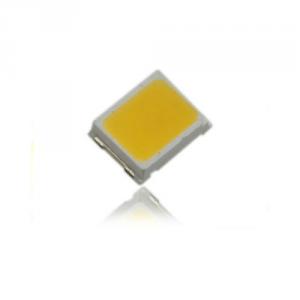

Professional Manufacturer 0.1W 2835 SMD LED

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 500 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Professional manufacturer 0.1w 2835 smd led

Basic parameters:

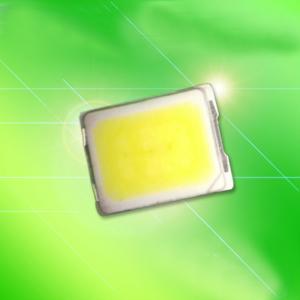

0.1w,2.8-3.4v,30mA,10-12m,5000-7000K( white)

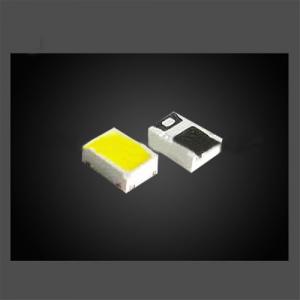

SMD 2835 LED 0.1W

Color Temperature:

2900-3200K warm white

5000-7000K (500K tolerance,such as 5000-5500K) natural white

7000-9000K cool white

9000-15000K cool white

More details for led products,pls contact Lisa Wei,skype ID: lisawei.getian

Applications: tube light, car light, strip light, panel light

Product Features:

1. 3 years warranty

2. Superior raw materials

3.low power consumption, High intensity

4. Certification:CE, RoHs

5.Long lifespan: 50000+ hours, low light decay

6.Professional LED manufacturer for 8 years

Our Advantage:

1.Over 8 years LED field history to offer professional service

2.Our engineer worked for Cree and Epistar who you can rely on.

3.TOP 50 LED manufacturer in China and TOP 10 LED manufacturer in Shenzhen.

4.All of our products has CE, ROHS and OEM/ ODM service are available

5.High quality chips from famous brand and strict inspection procedures

we specialized in high power led,smd led,cob led,led driver.

For high power led ,include 1w,3w,5w,10-500w high power led,RGB led

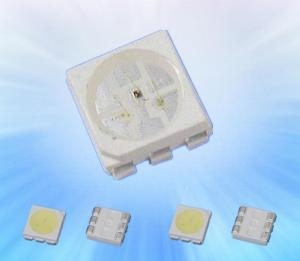

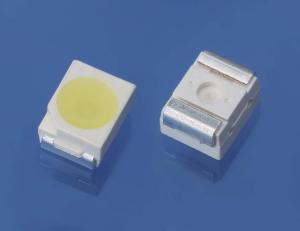

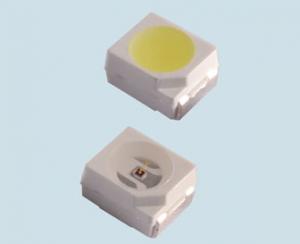

For smd led ,include 2835,3528,5050,5730,3014,3030

Available Color: Red, Green, Blue, Yellow, Orange, White, RGB LED,Amber.

Red color other wavelength: 620nm,625nm,630nm,640nm,650nm,660nm,850nm

Good raw materials used in production is as below

Chip:USA Bridgelux chip, Taiwan Epistar ,Epileds,Genesis chip

Silicon glue: USA Dowcorning (good glue has less lighting decreasing)

Phosphor Powder: USA Intermatix (good powder has better performance in lumens)

Gold wire: Germany Herqeus 1.0mil Gold wire(for bearing bigger current, gold wire has less electricity resistance than silver and cooper)

Led base:red/ black cooper base (for better thermal conductive/ dissipation)

Full Automatic machines

USA ASM die bonding machine, USA ASM wire welding and soldering machine

Japan Mushasi Power Spoting and Japan Mushasi glue sealing machine

More details for led products,pls contact Lisa Wei,skype ID: lisawei.getian

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

By Sea | 30-40 business days |

1. 3-5 business days for Sample Orders; 7-15 business days for Bulk Orders for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

- Q: What is the difference between SMT LED packaging with silicone and epoxy resin transparent package? What is the market situation of these two types of packaging?

- Epoxy resins turn yellow during short wave irradiation or long periods of high temperature, so they are very short lived when applied to high power lighting. That's why the LED lighting market is dominated by silica gel.But because of the low price of epoxy resin (silica gel and not at a level), and storage, use and processing is superior to silica gel, so the low power LED and some optical components still use epoxy resin package.

- Q: What should I notice when I want to solder 1206 LED patch type luminous tube on fine copper wire?,

- The peak reflow temperature: 260 degrees or below this temperature. (surface temperature) 2 temperature over 210 DEG C required time: 30 seconds or less than this time. 3 reflow times: no more than two times. 4 after reflow, LED needs to be cooled to room temperature before contact with colloid.

- Q: What is patch SMD-LED?

- This really do not know how to answer you, like a sheet of the same type of solder paste used to operate, it can be said that the plug-in is not, it is patch it!

- Q: Is the forward voltage drop of the patch LED too large or too small?

- The pressure drop in the normal range is generally better. The smaller the pressure drop, the lower the power dissipation. The more you save the electricity bill.But not to say that the smaller the better, not in the normal range of low pressure drop products may be defective.In addition, the uniformity of the LED pressure drop is also important.

- Q: Patch LED light does not flash, why?

- Hit the meter on the buzzer and measure the patch individually. If the flash is a patch, the light goes off.

- Q: Notes on patch LED

- Clean, do not use an unknown chemical liquid to clean the patch LED: an unknown chemical liquid may damage the patch LED. When necessary, immerse the patch LED in alcohol, less than 1 minutes at normal room temperature, and dry naturally for 15 minutes before starting to use

- Q: LED package and LED SMD LED lamp, what is the difference? Will the release agent be used in that part?

- They differ in form and belong to the SMDLED category. Encapsulation uses liquid silicone and epoxy resins as well. The patches are basically made of epoxy resin. Relatively speaking, the amount of liquid silica should be relatively large.

- Q: What does "1210" mean in patch LED?

- At present, most manufacturers of SMD light strip used by 3528 and 5050, and 3535 and 5630 in the majority, there are many of the 3528 and 5050 and 3535, such as patch LED used in automotive lighting.

- Q: The ten patch LED lights are connected in parallel. The rated power is 5 watts. How much voltage do you need?

- Shunt split current series split voltageIs your single lamp voltage rated voltageIn addition to the red and green LED lights, the voltage is between 2 and 2.4, and the other colors are 3 to 3.6V

- Q: Such as title, please have welding patch LED lamp experience expert guidance, do not search from the Internet to the theoretical knowledge, thank you!

- When soldering, the temperature is best to be lower, and the average welding temperature is about 360. That's enough, because the melting temperature of the tin wire is about 220 degrees, so if it is allowed, the temperature can be reduced as low as possible.

Send your message to us

Professional Manufacturer 0.1W 2835 SMD LED

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 500 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords