Polyester Packaging Tape with Aluminum Foil Tape Good Temperature Resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 3000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

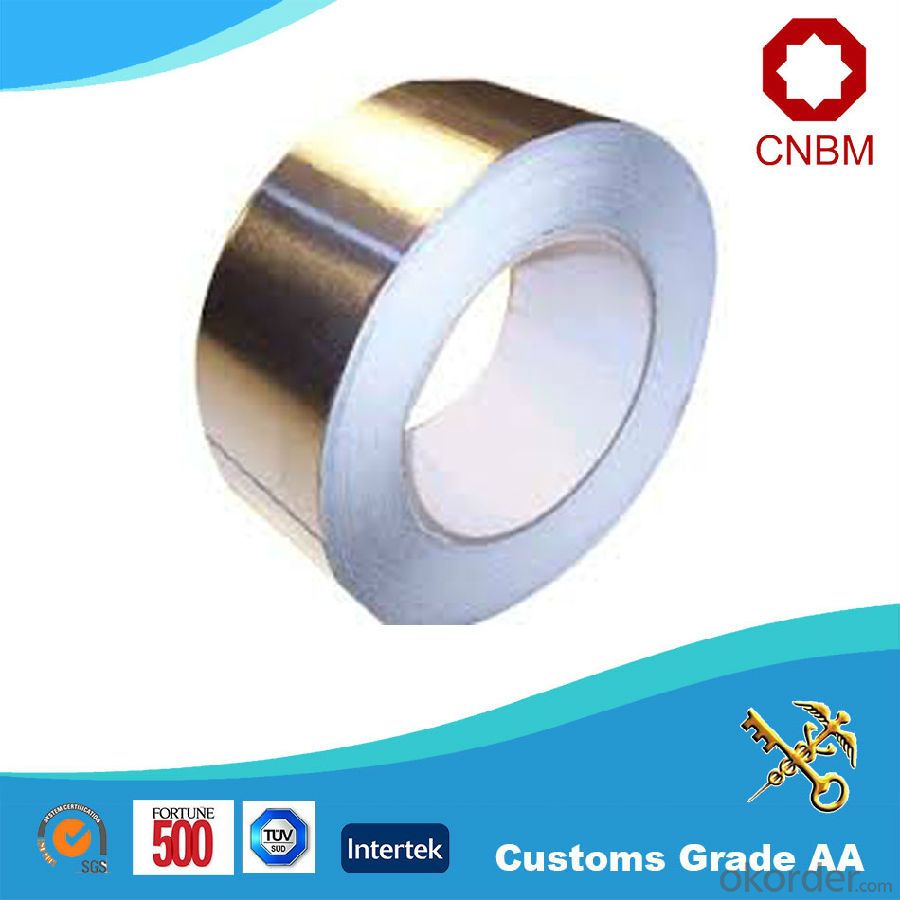

Aluminum Foil Tape Good Temperature Resistance

Product Description

Aluminum Foil Tape is made of aluminum foil as carrier. Features high peel adhesion with good tack, temperature and aging resistance, and water vapor resistance.

Features

1) High tensile strength aluminum foil made from special aluminum alloy, coated with aggressive solvent-based acrylic adhesive, which provides high peel adhesion and quick sticking

2) Designed for sealing joints and seams of foil jacketing in air-conditioning duct work

Data Sheet

Item | Aluminum Foil Tape |

Thickness (micron) | 25 |

Peel Adhesion (N/25mm) | 19 |

Tensile Strength(N/25mm) | 38 |

Service Temperature (℃) | -20 - +80 |

| Payment | TT & LC |

Packing | Rolls in Carton |

Certification | SGS and ISO9001 |

Production Line and Tests

Company

CNBM International Corp can guarantee you with high quality and stability. We have certificate, such as SGS and ISO9001. We have been supplied aluminum foil for over 20 years and have clients over 100 countries.

FAQ

1. What is specification ?

1) Foil thickness: 18, 22, 26μ

2) Roll width: 48, 50, 60, 72, 75, 96, 100mm

3) Roll length: 27, 30, 45, 50m

4) Log roll: 1.2 x 45m, 1.2 x 50m

5) Jumbo roll: 1.2 x 1200m, 1.2 x 1000m

2. What is the innner packing?

Cut roll: printed core and shrink wrapping

Log roll: cardboard wrapping

Jumbo roll: plastic film + corrugated board wrapping

3. What is the other packing?

Outer packing:

Cut roll: carton

Log roll: carton + pallet / wooden case

Jumbo roll: wooden case

4. Free Samples?

Yes, we would like sending free aluminum foil tape for you.

5. What are the certificate?

SGS and ISO9001

- Q: Can packaging tape be used for sealing plastic garment bags?

- Indeed, plastic garment bags can be effectively sealed using packaging tape. The primary purpose of packaging tape is to create a reliable and long-lasting seal on diverse materials, such as plastic. By utilizing packaging tape, one can ensure that the plastic garment bag remains tightly sealed, thereby safeguarding the garments inside from dust, moisture, and other harmful substances. This, in turn, prevents any potential damage or dirtiness. Furthermore, packaging tape is typically user-friendly, as it can be effortlessly cut with a dispenser or a pair of scissors, which adds to its convenience when sealing plastic garment bags.

- Q: Is packaging tape resistant to extreme pressure or weight?

- The purpose of packaging tape is to secure packages with a strong and reliable seal. However, the ability of the tape to withstand extreme pressure or weight can differ depending on its type and quality. Typically, packaging tapes are crafted from resilient materials such as polypropylene or polyester, enabling them to endure typical handling and transportation pressures. Nevertheless, it should be noted that packaging tape might not withstand excessively heavy loads or excessive pressure. In such instances, it is suggested to enhance the tape's strength by adding extra layers or employing heavy-duty tapes that are explicitly designed for high-pressure or weight-bearing purposes.

- Q: What are the benefits of using UV-resistant packaging tape?

- There are several benefits of using UV-resistant packaging tape. First and foremost, UV-resistant packaging tape is designed to withstand prolonged exposure to sunlight and prevents the tape from deteriorating or degrading over time. This is especially important when shipping or storing items outdoors or in areas with direct sunlight. UV-resistant tape can maintain its adhesive properties and structural integrity for longer periods, ensuring that packages remain securely sealed. Additionally, UV-resistant packaging tape helps protect the contents of packages from damage caused by UV rays. Sunlight can cause fading, discoloration, or degradation of certain materials, such as paper, fabrics, or plastics. By using UV-resistant tape, these items are shielded from the harmful effects of UV rays, preserving their quality and appearance. Another advantage of UV-resistant packaging tape is its long-lasting adhesion. Unlike regular packaging tape, which may lose its stickiness over time when exposed to sunlight, UV-resistant tape is specifically formulated to bond tightly and securely to various surfaces. This reliable adhesion minimizes the risk of packages coming open or items getting damaged during transit. Moreover, UV-resistant packaging tape provides added peace of mind for both the sender and the recipient. By using tape that is resistant to UV rays, businesses and individuals can ensure that their packages arrive in the same condition they were sent, maintaining the professional image and customer satisfaction. This is particularly crucial when shipping valuable or delicate items that require extra protection. In conclusion, the benefits of using UV-resistant packaging tape include enhanced durability, protection against UV damage, long-lasting adhesion, and increased confidence in package integrity. By choosing UV-resistant tape, individuals and businesses can safeguard their packages and the contents within, even when exposed to prolonged sunlight.

- Q: Is packaging tape easy to write on?

- Writing on packaging tape can be quite difficult due to its smooth and glossy surface. Most writing tools struggle to stick properly to the tape, resulting in smudged or faded writing. Furthermore, the adhesive properties of packaging tape can cause ink to bleed, making it challenging to achieve clean and precise writing. As a solution, it is recommended to use a permanent marker or a specialized pen specifically designed for non-porous surfaces such as plastic. These writing tools typically yield superior outcomes and ensure that your writing stays legible and intact.

- Q: Can packaging tape be used for bundling items together?

- Yes, packaging tape can be used for bundling items together.

- Q: Can packaging tape be used for other purposes?

- Packaging tape has a wide range of uses beyond its intended purpose of sealing packages. Its strong adhesive properties and durability make it suitable for various applications. One popular alternative use for packaging tape is organizing and bundling items together. It can be used to sort and secure cables, cords, loose items, or similar objects, effectively keeping them organized. Additionally, it can be used to temporarily attach items like posters or decorations to walls or surfaces without causing any damage. Furthermore, packaging tape is great for crafting and DIY projects. Its adhesive nature allows it to create both temporary and permanent bonds between different materials. It can repair torn papers, create labels or tabs, or even make personalized stickers. Its versatility, available in different widths and lengths, makes it a valuable tool for creative endeavors. Moreover, packaging tape can be used for household fixes and repairs. Its strong adhesive properties can temporarily mend broken items or reinforce weak joints. It can also provide a temporary seal for minor leaks or cracks until a proper repair can be done. In conclusion, packaging tape's strong adhesive properties and versatility make it suitable for various purposes beyond sealing packages. Whether for organizing, crafting, or quick fixes, having packaging tape on hand can be highly useful.

- Q: Can packaging tape be used for sealing pet supplies or accessories?

- Yes, packaging tape can certainly be used for sealing pet supplies or accessories. It provides a strong and secure seal that can keep the contents of the packaging safe and protected. Whether you need to seal pet food bags, pet toy packaging, or any other pet-related items, packaging tape can be an effective solution. It is easy to use, durable, and readily available in various sizes and strengths. Just make sure to choose a tape that is appropriate for the specific weight and size of the package you are sealing, to ensure proper protection.

- Q: Can packaging tape be used for sealing plastic folders?

- Yes, packaging tape can be used for sealing plastic folders. Packaging tape is designed to be strong and adhesive, making it suitable for securing and sealing various materials including plastic folders. It can help keep the contents of the folder secure and protected. However, it is important to ensure that the tape is applied properly and securely to ensure a tight seal. Additionally, it is recommended to use a clear packaging tape that will not obstruct the visibility of the folder's contents.

- Q: Can packaging tape be used for sealing packages with heavy-duty construction materials?

- Yes, packaging tape can be used for sealing packages with heavy-duty construction materials. However, it is recommended to use a high-quality, heavy-duty packaging tape specifically designed for securing heavy items.

- Q: Does packaging tape have any specific certifications or standards?

- Yes, packaging tape can have specific certifications or standards. Some common certifications or standards for packaging tape include ISO 9001 (quality management), ISO 14001 (environmental management), and ASTM D1974 (standard specification for sealing and securing pressure-sensitive tape for packaging). Additionally, certain industries may have their own specific certifications or standards for packaging tape, such as food-safe certifications for packaging tape used in the food industry.

Send your message to us

Polyester Packaging Tape with Aluminum Foil Tape Good Temperature Resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 3000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords