Nelson Stud Shear Connector for Studs Welding with ISO 13918

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details

Basic Info.

Model NO.:M19*100

Material:Carbon Steel

Surface Finishing:Plain&Black

Grade:A

Certification:ISO, CE, SGS

Customized:Customized

Product Name:Nelson Studs

Type:Shear Studs

Raw Material:Carbon Steel Ml15al (Swrch15A)

Support Standard:ISO 13918 ; GB/T10433; Aws D1.1

Surface Treatment:Plain &Black

Diameter:M10 M13 M16 M19 M22 M25

Length:40-300mm

Tensile Strength:>= 450n/Mm2

Yield Point:>= 350n/Mm2

Elongation Percentage:>= 15%

Export Markets:Global

Additional Info.

Packing:Carton &Barrel &Pallet for Welding Shear Stud

Standard:ISO 13918; GB/T10433; AWS D1.1

Origin:Tianjin

HS Code:7318290000

Production Capacity:2000 Ton/Tons Per Month 100X20′′gp Shear Stud

Product Description

Shear Connector For Stud Welding

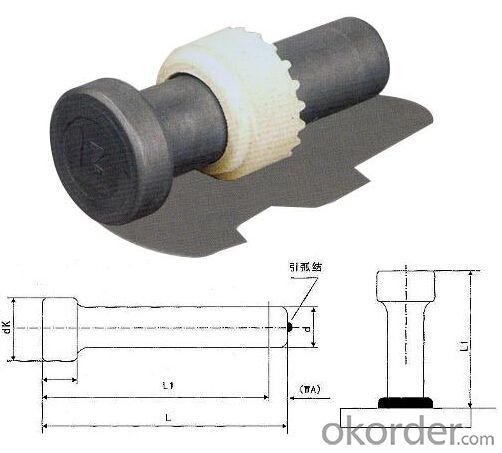

Shear Connector Studs are designed to tie the concrete to the steel beams and to resist shear loadings

between the concrete slab and steel beam in composite construction.

Shear connectors on the top flanges of the steel girders provide the means to achieve composite action between the slab and the girders, thus increasing both stiffness and strength.

Fasteners used to attach a structure or object to concrete. They can be used with many base materials including concrete, brick and block. Shear connectors are welded to surfaces in order to resist shear between elements of a composite beam.

Shear studs are used in stud welding to secure steel framed buildings to create a shear connection between

the steel and the concrete. We supply and fix all available sizes of welded shear studs for through deck

and straight to steel welding.

Burn off value shown are for welding to bare steel.

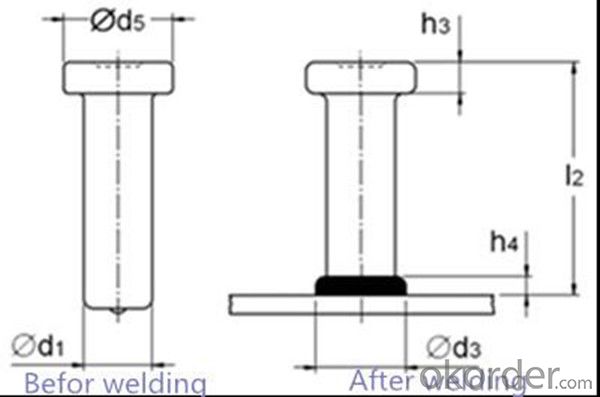

Length: Length is before weld. Stud when welded to base metal will be approximately 5mm shorter after weld and when welded through deck 10mm shorter after weld. Lengths for shear connect studs are generally set by governing specification

Shear studs are used in stud welding to secure steel framed buildings to create a shear connection between the steel and the concrete. We supply and fix all available sizes of welded shear studs for through deck and straight to steel welding.

All our products meet the current standards and specifications

The ISO 13918 SINOARSTM shear studs (shear connectors) use the ISO13918 standard Type UF and PF ceramic

ferrules,other special type available upon request.

When inquire prices and ordering, please specify name, standard, type, specification (LBW), quantity, special requirements(if have), etc., eg.

Shear Stud, ISO 13918, Type SD, 22x150 (LBW), 60,000 Pieces.

Production specification

| ||||||

d1-0.4 | 10 | 13 | 16 | 19 | 22 | 25 |

d5±0.3 | 19 | 25 | 32 | 32 | 35 | 41 |

d3±0.3 | 13 | 17 | 21 | 23 | 29 | 31 |

h3±0.5 | 7 | 8 | 8 | 10 | 10 | 12 |

h4 | 2.5 | 3 | 4.5 | 6 | 6 | 7 |

L1±1.5 | 40-105 | 40-160 | 40-200 | 40-250 | 60-250 | 60-250 |

Burn off | 3 | 3 | 4 | 5 | 5 | 6 |

Ferrule | UF10 | UF13 | UF16 | UF19 | UF22 | UF25 |

1.Burn off value shown are for welding to bare steel

2.There are two kinds of ceramic ferrule, one is through deck type which has 8 teeth,

the other one is common type which has 18 teeth.

The price is same for these two types.

3.The UFB type ceramic ferrule are for through deck welding , with 8 teeth !

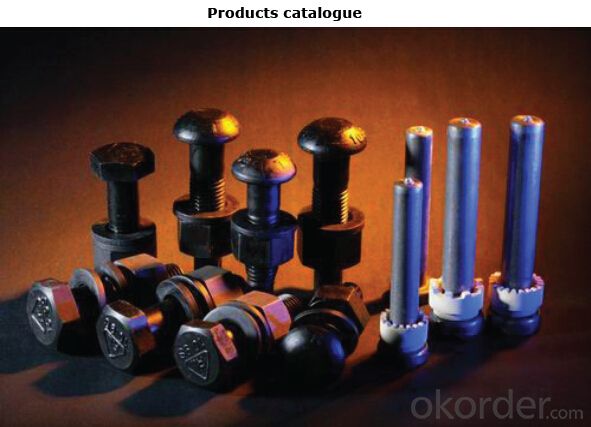

Prouduct Show:

FAQ:

Acceptable payment term and way?

T/T,L/C, T/T + L/C,

Acceptable price term?

FOB CNF CIF DDU CPT

Do you accept OA payment terms?

Yes, sure, but it normally depending on the order value

Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

What is the validity of your quotation?

Normally 7 days.

What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: What are some of the common fastener products?

- There is also a fastener called "pin" This fastener is generally used to locate the parts, and sometimes can also be connected to the fixed role, in addition to a part can be used to transmit power or lock other fasteners.

- Q: what parts do Fasteners include

- A type of fastener that has no head and only the ends that are threaded at both ends. When connected, it must be screwed into the part with internal screw hole, the other end through the through hole with the parts, and then screw the nut, even if the two parts fastened into a whole. This type of connection is called a stud connection and is a detachable connection. Mainly used for connecting parts of a larger thickness, requiring a compact structure, or because of frequent demolition, should not be used bolted connection occasions.

- Q: High-strength screw standard parts of the quality of what data

- Material: Does the chemical composition meet the standard requirements Appearance: Good surface treatment: Does it meet the standard requirements? If 1 and 4 problems, this batch of bolts directly failed,

- Q: Bolts and other connection fasteners some points A B C grade what it means

- The same standard number! Different grades of bolts, their material is not the same! Just their detection method just the same!

- Q: In the fastener industry, 1018 refers to what material

- Low carbon steel, can only be used to produce the general screw class, and 102A almost

- Q: Is it hard to heat the fasteners?

- Fasteners are also known as standard parts, which are mainly heat-treated according to the material of the product.

- Q: Does the fastener include screws?

- Fastener fasteners are also known as standard parts on the market and are a generic term for a class of mechanical parts that are used when two or more parts (or components) are tightly connected as a unit. It is characterized by a wide variety of specifications, performance purposes vary, and standardization, serialization, the degree of generalization is very high. Fasteners are the most widely used mechanical base pieces and are in great demand.

- Q: What fasteners are manufacturers in China?

- (3) Ningbo Jinding Fasteners Co., Ltd. (4) Jin billion Industrial Co., Ltd. (5) Zhejiang Zhapu Industrial Co., Ltd. (3) Changshu Standard Parts Factory; (2) Shanghai Standard Five High Strength Fasteners Co.

- Q: Are there categories of fasteners classified by material?

- According to the use of different materials, fasteners are divided into carbon structural steel fasteners, alloy structural steel fasteners, stainless steel fasteners, high temperature alloy fasteners, aluminum alloy fasteners, titanium fasteners, titanium Niobium alloy fasteners and non-metallic fasteners.

- Q: Fasteners are used in what areas?

- Fasteners are a class of mechanical parts that are used for fastening connections and are widely used. All kinds of fasteners can be seen in all kinds of machinery, equipment, vehicles, ships, railways, bridges, buildings, structures, tools, instruments, instruments and supplies. If the fasteners are removed from reality, many of the equipment,

Send your message to us

Nelson Stud Shear Connector for Studs Welding with ISO 13918

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords