Hot rolled steel wire rod in coils low carbon

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 18421 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Drawing Grade wire rods are used by downstream industries for various applications such as making

wires for welded mesh, nails, hangers, screws, chain link & gabion fencing, wire nets, barbed wires

and binding wires.

Our service:

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing

consistently high standards of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in

customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with

shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can

achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our

key markets. To maintain our position as market leader we must continue to add

value in all that we do.

Product Description :

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material/steel grade | Q195-Q235,SAE1006B,SAE1006CR, SAE1008B, SAE1008CR, SAE1010B, SAE1018B, or according to customers requirements |

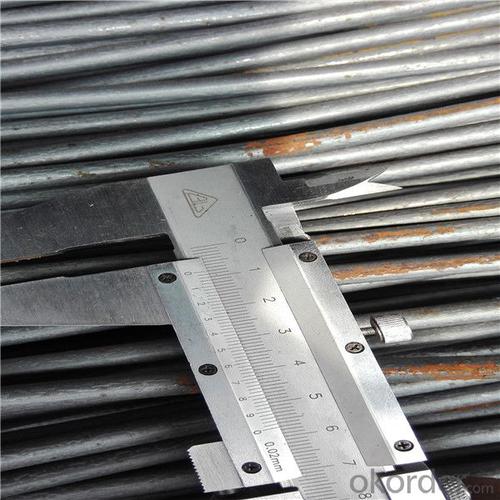

Wire Gauge | 5.5-12mm |

Coil weight | 1.8-2.1mts |

MOQ | 25MT |

Delivery Time | 15-30 days after receipt of L/C or deposit by T/T |

Packing | In coil and load in container, if large quantity, by bulk vessel; Can be packed as customers' special requirements |

Payment terms | 1).100% irrevocable L/C at sight. 2).30% T/T prepaid and the balance against the copy of B/L. 3).30% T/T prepaid and the balance against L/C |

Application | widely used in machinery parts, manufacturing industry, electronics industry, metal tools and others |

Application :

Mainly used in building and construction as binding wire, tie wire and baling wire; also can be make

for wire mesh.

Packing :

Hot-rolled wire rod is held in a unit with at least four steel straps in the

transverse direction and transported and stored without further packaging.

Before

the steel strapping is applied, the wire rod must be sufficiently compressed.

The strapping is fixed in the transverse direction with a single circumferential

strap so that the strapping does not slip and cause the coil to come apart.

FAQ:

1.Q:Can you accept mixed order?

A: Yes, mixed acceptable .

2. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

3. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the

professional sales team to follow up your case.

4. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3

-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: What are the main factors affecting the price of steel wire rod?

- The price of steel wire rod is influenced by several main factors. 1. Raw material costs: The cost of the raw materials used in the production of steel wire rod, primarily iron ore and scrap metal, play a significant role in determining its price. Fluctuations in the prices of these raw materials can directly impact the price of steel wire rod. 2. Energy costs: Steel production is an energy-intensive process, and the price of energy, particularly electricity and fuel, can greatly affect the cost of manufacturing steel wire rod. Changes in energy prices, such as fluctuations in oil prices or government policies on carbon emissions, can impact the overall price of the product. 3. Supply and demand dynamics: The supply and demand for steel wire rod in the market can influence its price. If the demand for steel wire rod increases while the supply remains constant, prices are likely to rise. Conversely, if there is excess supply compared to demand, prices may decrease. 4. Market competition: The level of competition among steel wire rod manufacturers can impact its price. In a highly competitive market, manufacturers may lower their prices to attract customers, leading to a decrease in the overall price of the product. Conversely, limited competition can result in higher prices. 5. International trade and tariffs: Steel wire rod is often subject to international trade and tariffs. Trade policies, such as import restrictions or tariffs imposed on steel wire rod by governments, can affect its price by limiting supply or increasing costs. 6. Currency exchange rates: Steel wire rod is traded globally, and fluctuations in currency exchange rates can impact its price. If the currency in which steel wire rod is priced strengthens against other currencies, it may lead to an increase in its price. 7. Technological advancements: Advancements in technology used in the production of steel wire rod can influence its price. Newer technologies may result in higher efficiency, reducing production costs and potentially lowering the price of the product. Overall, the price of steel wire rod is influenced by a combination of factors, including raw material costs, energy costs, supply and demand dynamics, market competition, international trade and tariffs, currency exchange rates, and technological advancements. Monitoring these factors is crucial for understanding and predicting fluctuations in the price of steel wire rod.

- Q: How are steel wire rods used in the manufacturing of nails?

- When manufacturing nails, steel wire rods play a vital role. These rods, usually made from high-quality steel known for its strength and durability, are crucial components. To begin the process, the appropriate steel wire rod is carefully selected based on the desired nail specifications. The diameter and tensile strength of the rod are chosen with great care to ensure that the final nail meets the required standards. Once the steel wire rods have been chosen, they are introduced into a nail-making machine. This machine is composed of different sections that collaborate to transform the wire rod into a nail. The first section of the machine is responsible for straightening the wire rod, ensuring its correct alignment. Then, the rod is passed to the cutting section, where it is cut into the desired length for the nail. Following that, the rod enters the forming section, where it is shaped into the nail's basic structure. This section employs a combination of mechanical force and heat to mold the wire rod. After the forming process, the nail goes through a series of rollers and dies to refine its shape and enhance its strength. These rollers and dies give the nail its characteristic head, shank, and point. Lastly, the nails are cooled and subjected to quality control inspections. Any defective nails are discarded, while the acceptable ones are collected and packaged for distribution. In conclusion, steel wire rods are indispensable in the manufacturing of nails. They provide the necessary raw material to create sturdy and reliable nails. The strength and durability of steel make it an ideal material for nails, enabling them to withstand the pressures and forces they will encounter during use.

- Q: How is steel wire rod used in the production of wire harnesses?

- Wire harnesses, found in industries like automotive, aerospace, and electronics, rely on steel wire rods as a fundamental component. These rods, typically composed of carbon steel, undergo a series of steps to become wires with different dimensions. To improve durability and flexibility, the rods are initially cleaned and coated with a lubricant. Once prepared, the rods are drawn through dies to decrease their diameter and increase their length. This drawing process aligns the steel molecules, resulting in stronger and more consistent wires. The drawn wires are then annealed to relieve internal stresses and enhance their ductility. The resulting smooth and uniform steel wires are then utilized in wire harness production. These wires are cut to specified lengths and stripped at specific points to expose the conductive metal. The exposed ends are either soldered or crimped to connectors, terminals, or other electrical components. Finally, the wires are bundled together using techniques like braiding, taping, or plastic molding to create the final wire harness. Steel wire rods hold immense importance in wire harness production due to their essential role in providing strength and conductivity for efficient electrical connections. The quality and properties of the steel wire rod directly impact the performance and reliability of wire harnesses, emphasizing the necessity of using high-quality materials in their manufacturing process.

- Q: How is steel wire rod used in the manufacturing of wire cloths?

- Steel wire rod is used in the manufacturing of wire cloths as it serves as the raw material for producing the wires that make up the cloth. The steel wire rod is drawn through a series of dies to reduce its diameter and increase its length, resulting in a thin, strong wire. This wire is then woven or welded together to create the wire cloth, which is commonly used for filtration, screening, and sieving applications in various industries.

- Q: What are the common production processes for nickel-coated steel wire rod?

- The common production processes for nickel-coated steel wire rod include cleaning and pickling the steel rod, pre-coating it with a layer of copper to enhance adhesion, passing it through a nickel plating bath to deposit a layer of nickel, and finally, subjecting it to heat treatment to improve the coating's properties.

- Q: What are the advantages of using steel wire rod over other materials?

- Steel wire rod offers numerous advantages compared to other materials. Firstly, its exceptional strength and durability make it ideal for applications requiring reliability. It can withstand heavy loads and stresses, making it suitable for industries such as construction, automotive, and manufacturing. Secondly, steel wire rod is highly versatile as it can be easily fabricated into various shapes and sizes to meet specific project requirements. This flexibility allows for a wide range of applications, including wire ropes, springs, cables, fencing, and reinforcement in concrete structures. Moreover, steel wire rod exhibits excellent corrosion resistance properties, ensuring a longer lifespan and reduced maintenance costs. This makes it suitable for outdoor and marine applications, where exposure to moisture and harsh weather conditions is common. Additionally, steel wire rod is cost-effective due to its abundance and widespread availability. Its durability and resistance to wear and tear also contribute to lower replacement and maintenance costs in the long run. Lastly, steel wire rod promotes environmental sustainability as steel is one of the most recycled materials globally. Using steel wire rod helps conserve natural resources and reduce carbon emissions by reducing the need for new production. In summary, the advantages of steel wire rod include its exceptional strength, versatility, corrosion resistance, cost-effectiveness, and environmental sustainability. These qualities make it a preferred choice for a wide range of applications across different industries.

- Q: What are the common applications of spring steel wire rod?

- Spring steel wire rods are widely used in various industries due to their unique properties and characteristics. Some of the common applications of spring steel wire rods include: 1. Springs: Spring steel wire rods are primarily used in the manufacturing of springs. They provide elasticity and flexibility, making them ideal for applications that require constant or intermittent compression or extension, such as automotive suspension systems, mattress springs, door locks, and industrial machinery. 2. Fasteners: Spring steel wire rods are commonly used to produce fasteners like bolts, screws, and rivets. Their high tensile strength and resistance to deformation ensure that these fasteners can withstand significant stress and maintain their structural integrity. 3. Wire forms: Due to their excellent formability, spring steel wire rods are often utilized in the production of various wire forms, including hooks, clips, rings, and brackets. These wire forms find applications in industries like construction, automotive, aerospace, and household appliances. 4. Musical instruments: Spring steel wire rods are extensively used in the manufacturing of musical instruments, particularly in the construction of piano strings and guitar strings. The high tensile strength and elasticity of spring steel wire rods result in strings that can produce clear and resonant tones. 5. Fencing and mesh: Spring steel wire rods are commonly used in the production of fences, mesh screens, and wire grids. Their high strength and durability make them suitable for security fencing, animal enclosures, and industrial sieving applications. 6. Suspension systems: Spring steel wire rods are widely used in the automotive industry for manufacturing suspension systems. These rods provide the necessary flexibility and resilience to absorb shocks and vibrations, ensuring a smooth and comfortable ride. 7. Electrical conductors: Spring steel wire rods are sometimes used as conductors in electrical applications. Their high conductivity and ability to withstand high temperatures make them suitable for certain electrical wiring and heating elements. 8. Oil and gas industry: Spring steel wire rods find applications in the oil and gas industry for various purposes, such as downhole tools, wireline cables, and coiled tubing. Their high strength and resistance to corrosion make them suitable for demanding environments. Overall, spring steel wire rods are versatile and find applications in a wide range of industries due to their unique combination of strength, elasticity, formability, and resistance to deformation.

- Q: What are the different types of steel wire rod surface defects and their repair methods?

- Steel wire rods can experience different types of surface defects, each necessitating a unique repair approach. Common defects include pits, scale, scratches, and cracks. Pits manifest as small cavities on the wire rod's surface, resulting from factors like corrosion or mishandling. To rectify pits, the affected area can be ground down and then polished to restore a smooth surface. Scale refers to the flaky residue that forms during the wire rod's manufacturing process. It can be eliminated through chemical agents or mechanical techniques such as brushing or blasting. Following scale removal, the wire rod can be coated with a protective layer to prevent future formation. Scratches are shallow grooves that can occur during handling or transportation. Minor scratches can be resolved by using abrasives or polishing compounds to buff them out. For deeper scratches, the affected area may need to be ground and then polished to match the surrounding surface. Cracks are more severe defects resulting from stress, improper cooling, or material flaws. Repairing cracks typically involves cutting out the affected section and subsequently welding or brazing it back together. In some cases, heat treatment may be necessary to restore the wire rod's strength and integrity. It's important to note that the repair methods mentioned may vary depending on the defect's severity and nature. It is always advisable to consult a professional or follow the manufacturer's guidelines to ensure appropriate repair of steel wire rod surface defects.

- Q: How is steel wire rod different from steel bar?

- Steel wire rod and steel bar are both made from steel but they differ in terms of their shape, size, and usage. Steel wire rod is typically cylindrical in shape and has a smaller diameter compared to steel bar. It is mainly used in the production of wire and various wire-based products, such as nails, screws, and wire mesh. On the other hand, steel bar is generally longer and thicker, with a solid and straight profile. It is commonly used in construction, manufacturing, and infrastructure projects, where its strength and durability are crucial.

- Q: What are the different types of steel wire rod surface cleaning tools?

- There are several different types of steel wire rod surface cleaning tools available in the market. These tools are designed to remove dirt, rust, and other contaminants from the surface of steel wire rods, ensuring a clean and smooth finish. One common type of cleaning tool is a wire brush. These brushes have stiff bristles made from steel or other materials that are capable of removing rust and loose debris from the surface of the wire rod. Wire brushes are available in various shapes and sizes, allowing users to choose the one that best fits their needs. Another type of cleaning tool is a sanding disc or wheel. These tools are typically made from abrasive materials such as sandpaper or grinding wheels. They are mounted on a rotating machine, and when pressed against the surface of the wire rod, they remove rust and other contaminants through abrasion. Chemical cleaning agents are also used to clean steel wire rod surfaces. These agents are usually applied using a brush or spray, and they work by breaking down and dissolving the contaminants on the surface. After application, the surface is usually rinsed with water to remove the cleaning agent and any remaining residue. Ultrasonic cleaners are another option for cleaning steel wire rod surfaces. These machines use high-frequency sound waves to create tiny bubbles in a cleaning solution. As the bubbles implode, they create a scrubbing action that removes dirt, rust, and other contaminants from the surface of the wire rod. In addition to these tools, there are also specialized cleaning machines available for larger-scale operations. These machines often use a combination of mechanical, chemical, and/or ultrasonic cleaning methods to ensure a thorough and efficient cleaning process. Overall, the choice of cleaning tool will depend on the specific needs and requirements of the user. It is important to consider factors such as the extent of contamination, the desired finish, and the size of the wire rod when selecting the appropriate cleaning tool.

Send your message to us

Hot rolled steel wire rod in coils low carbon

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 18421 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords