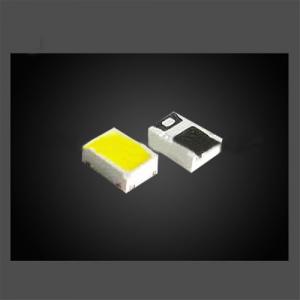

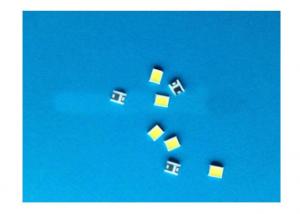

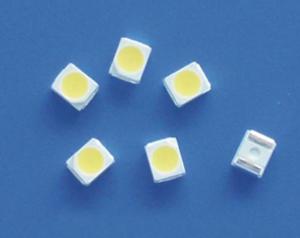

High Quality Newest 0.2W 20 to 25Lm 5050 White Top SMD LED

- Loading Port:

- Xiamen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 10000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Feature

LED light source , no pollution, no flicker, no noise

Lifetime: 50,000 hrs (ta=25°C)

ta: -20~35(-4°F ~ 95°F)

CCT: 2700K 3000K 4000K 5000K 6500K

Material: Aluminum alloy

Specification:

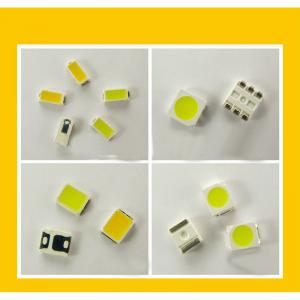

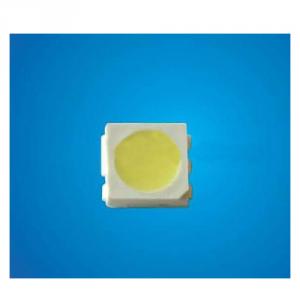

0.2W white 5050 top smd LED, 20-25lm/pc, CRI>80,dimension:5.0mm*5.0mm*1.6mm, 2kpcs per reel.

Advantages

1/ LED is RoHS compliance.

2/ Luminous fading less than 6.9% after 30,000hours, which is compliant to LM80 lab test.

Application:

Available for light souce of LED lights, such as LED tube, LED bulb, LED ceiling light, LED panel, LED downlight, etc.

Our services:

1. Your inquiry related to our products or prices will be replied in 24 hours;

2. Well-trained and experienced staffs will serve you and your clients in fluent English;

3. Both OEM and ODM are welcomed;

4. Distributor ship is offered for your unique design and some our current models;

5. Protection of your sales area, ideas of design and all your private information;

6. We are pleasure to provide you Led information, lighting solution and suggestions, technical support;

7. Certificate of origin (Form A, Form E, Form F) can be offered according to your requirements.

Packing and delivery

Package:

Standard packing inside, cartons outside

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

By sea | 30-40 business days |

1. 3-10 business days for Sample Orders; 7-40 business days for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address.

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

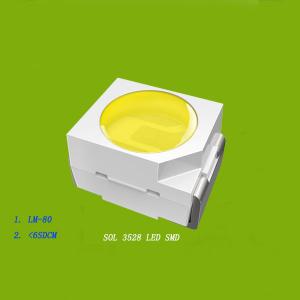

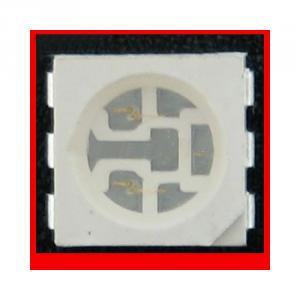

- Q: 0603,0805,1206,3020,3528,5050,355 what is the current and voltage of these patch LED? Please give advice!

- LED patch: 0603, 0805, 1206, 1210, 5050. The 0603: conversion to metric is 1005, that of the LED element length is 1.0mm, width is 0.5mm. The trade is abbreviated as 1005, and the English name is 0603. The 0805: conversion to metric is 2125, that of the LED element length is 2.0mm, width is referred to as the 2125 inch 1.25mm. industry, it is 0805. The 1206: conversion to metric is 3216, that of the LED element length is 3.2mm, width is 1.6mm. The trade is abbreviated as 3216, and the English name is 1206. The 1210: conversion to metric is 3528, that of the LED element length is 3.5mm, width is 2.8mm. The trade is abbreviated as 3528, and the English name is 1210. The 5050: This is a metric called, said that the LED element length is 5.0mm, width is 5.0mm. Industry abbreviation 5050

- Q: LED patch lamp band, how to calculate how many watts a meter, such as 3528-60 beads is how much?

- 3528-60 is 60 meters per lamp, 3528 SMD lamp with no 5050 light, about 10 watts per meter. Copper wires have less resistance and may be less than 10 watts per meter.

- Q: What should I notice when I want to solder 1206 LED patch type luminous tube on fine copper wire?,

- It is best to use a hot-air gun heat transfer high air volume adjustable low moment welding, the specific heat jump to the appropriate place to see what you use what kind of welding wire, welding wire of different because of the different melting point impurities also some differences. The air volume is too high, easy to blow the original

- Q: How can I install the patch LED lamp belt on the wood chip casting board? With double-sided glue will be hot, and can not use the clip on the screw, what should I do?

- More attention is paid to the lamp with waterproof and the installation of a solid in the outdoor installation, outdoor installation often adopts the mode of fixed card slot, need to cut and connected place, and indoor installation, just need another with waterproof glue, waterproof effect to consolidate the connection point.

- Q: LED light SMD LED package in what form, trouble you under the guidance of...

- Draw your own line, mm is replaced by mil on the line, with vernier caliper measurement, or know the model, count the number of mil. For example, 5050 is a close square with a width of 5.0mm*5.0mmInline LED (such as straw hat lights, 5mm), piranha LED, surface mount LEDSinglechip collection from hardware to software chm

- Q: How many volts is a single LED on the LED patch band?

- The single LED on the LED patch band is around 3.3V.LED light emitting diode, which is a nonlinear component, its operating voltage (tube pressure drop) is also different: ordinary red LED about 1.5 V; ordinary green LED about 1.8 V; bright white LED up to 3.3 V or so.

- Q: What are the storage requirements of SMT patch LED (LED)?

- Moisture-proof packing- anti SMD LED in the transport and storage of moisture absorption, SMD LED shall be placed in sealed moisture-proof bag, inside put damp proof agent for protection, and placed the humidity humidity SMD display card packaging bag.

- Q: What is the difference in performance between the LED plug-in and the LED patch?

- The cooling of the plug-in is not good, because the plug-in's lamp foot, in order to save costs, generally use iron plus coating, heat conduction is not very good.The strength of aluminium alloy is not enough, it is easy to break, and copper is expensive.Relatively speaking, the patch is good, because the heat is welded on the PCB, copper or direct aluminum substrate cooling, patches near.Otherwise, why do high-power patch it?!SMT direct placement machine, a high degree of automation, low rate of bad.

- Q: What does "1210" mean in patch LED?

- 1210 refers to the lamp specifications.LED common lamp specifications and parameters of patch0603, 0805, 1210, 3528, 5050 refers to the LED lamp belt, often used in light-emitting components ----LED size (English / Metric) name, for example, 0603 refers to the length of 0.06 inches, width of 0.03 inches. But note that the 3528 and 5050 units are metric

- Q: Patch LED light broken one, short circuit can use it?

- Can not casually short-circuit, according to the LED connection, but also to see the power supply voltage and current, all the LED can not flow. Any short circuit may cause excess LED to flow over or over, causing a chain reaction, a bad string,...... .

Send your message to us

High Quality Newest 0.2W 20 to 25Lm 5050 White Top SMD LED

- Loading Port:

- Xiamen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 10000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches