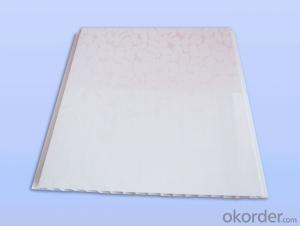

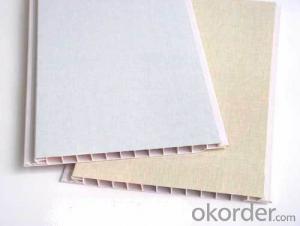

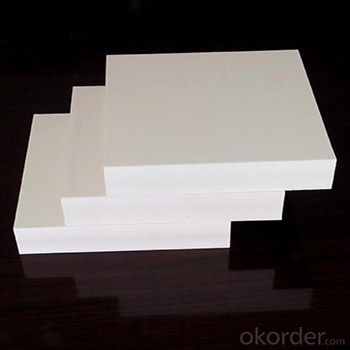

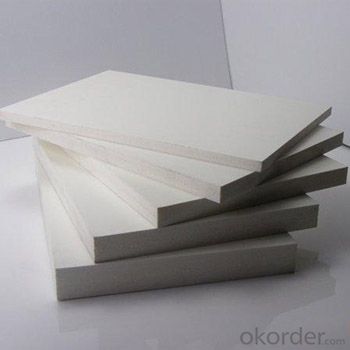

Plastic Sheets - High Density White 18mm PVC Foam Board for Furniture Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Introduction

WPC formwork sheet is made by PVC resin and wood powder(or bamboo power) at a certain ratio, added with special additives and extruded at high temperature, which specially made for formwork application. It is a ideal material for replacing formwork plywood.

Wood plastic composite with a flexible application, can be applied to any field of wood processing. So far, it is the best environmental protection material to replace wood, which is the most widely used in wood and plastic building products. It is the latest trend in materials for garden furniture and other outdoor applications, especially for terrace decking and also for weatherboarding and fencing panels.protection material to replace wood, which is the most widely used in wood and plastic building products. It is the latest trend in materials for garden furniture and other outdoor applications, especially for the cabinet in kitchen & bathroom, advertising, traffic and transit, industry, building and pholstering ,etc.

2.Mainly Feature

1) Light weight, waterproof

2) Good hardness with a smooth and glossy surface

3) Excellent formability

4) High impact strength

5) Good abrasion resistance

6) Excellent chemical and corrosion resistance

7) Easy to install and clean

8) Recyclable with a long service life

9) Dimensional accuracy

3.pvc foam board printing service advantage

| Why choose custom sticker printing , pvc coated tarpaulin banner poster | |

| 1. Durable, UV and water resistant, perfect pefermance for indoor&outdoor use | |

| 2. We offer various options technical support anywhere you like . | |

| 4. can be used for a long time | |

| Outdoor pvc banner printing , pvc coated tarpaulin banner poster characteristics | |

| 1. Different types material and print model for choosen | |

| 2. Customized,and provide OEM & ODM service | |

| 3. Good quality at competitive price in fast delivery | |

| 4. Professional digital printing company from 2003 | |

| Outdoor cafe barrier vinyl advertising banner for sale specification | |

| Signs & printing option | 1. pvc foam board for printing , Sintra board printing , correx board, Magnetic sign for your choose |

| 2. Single & double sides | |

| 3.UV & rain resistant | |

| 4. Inkjet/Eco-friendly/UV print | |

| Banner size options | 1. Max width 1.2 x 2.4 m |

| 2. Mini width 10cm by 10cm | |

| 3. Larger size need joint and stitch faucet | |

4.photo

- Q: Can plastic sheets be used for DIY lampshades?

- Yes, plastic sheets can be used for DIY lampshades. Plastic sheets are versatile and can be easily cut and shaped to create unique lampshade designs. They are also durable and can withstand heat from the light bulb. However, it is important to choose the right type of plastic that is safe for use with lighting fixtures and to ensure proper ventilation for heat dissipation.

- Q: What is the difference between EPS insulation board and XPS insulation board?

- XPS thermal conductivity is smaller than EPS, and has high heat resistance, low linear expansion ratio, the characteristics of the low, the obturator structure rate reached more than 99%, the formation of a vacuum layer, avoid air flow cooling, to ensure that the insulation performance of lasting and stable, with respect to the obturator rate of EPS 80%, the advantage is self-evident. Practice has proved that the insulation effect of 30mm thick XPS insulation board is equivalent to that of 50mm thick EPS insulation board and 120mm thick cement perlite. Therefore, in order to achieve the same insulation effect, the insulation thickness of EPS can be about 30% thinner than that of XPS. But since the price of XPS is about 2 times that of EPS, the economy of XPS is still not as good as that of EPS.

- Q: I would appreciate anyones help on this.I have to have a custom high-detailed graphic printed onto a sheet of plastic measuring 25 and 3/4 by 27. I'm assuming I will need a specialist service, but I'm not really too sure where to start, or how much this will cost me. This will be a custom made banner for an arcade machine, if anyone's interested. Can anyone direct me towards services, or even give me an idea of prices? I live in Essex, UK, if anyone can find somewhere local, I would greatly appreciate it!Thanks guys!-Kirsty

- check okorder

- Q: Are plastic sheets eco-friendly?

- No, plastic sheets are not eco-friendly. They are made from non-renewable fossil fuels and take hundreds of years to decompose, contributing to landfill waste and pollution. Additionally, the production of plastic sheets involves harmful chemicals and energy-intensive processes.

- Q: Do plastic sheets have any limitations or disadvantages?

- Yes, plastic sheets have limitations and disadvantages. They are not as durable as other materials such as metal or glass, which means they can easily crack, break, or warp over time. Additionally, plastic sheets are less heat resistant, making them unsuitable for applications where high temperatures are involved. They can also be prone to scratching and can accumulate static electricity. Moreover, certain types of plastic sheets may release harmful chemicals when exposed to certain conditions, posing health and environmental risks.

- Q: Are plastic sheets resistant to chemicals used in industrial processes?

- Yes, plastic sheets are generally resistant to the chemicals used in industrial processes. They are designed to withstand a wide range of chemicals, making them a suitable choice for various industrial applications.

- Q: Are plastic sheets resistant to cracking in freezing temperatures?

- No, plastic sheets are not generally resistant to cracking in freezing temperatures.

- Q: Are plastic sheets resistant to chemicals used in cleaning products?

- Yes, plastic sheets are generally resistant to chemicals used in cleaning products.

- Q: Plastic NPP board, there is no poison?

- PP engineering plastics are called polypropylene. It is a fine kind of resin developed after nylon. It is a kind of linear polymer with high density, no side chain and high crystallinity. It has excellent comprehensive properties. PP has good solvent resistance, oil resistance, weak acid resistance, weak alkali and other properties. POM has a high hardness and steel, has a high degree of creep and stress relaxation ability, excellent wear resistance, self-lubricating, and fatigue, and other engineering plastics can not be compared.

- Q: Can You Pay Someone At Home Depot To Cut A Sheet Of Plexiglass Into A Certain Shape Once You've Bought It?

- I don't know that Home Depot cuts plastic sheeting at all, though they will cut woods. I'm pretty sure they only make straight cuts though (the first cut may be free), not curves or angled lines. You might want to check out a plastics store though, since they'll usually cut plastics into almost any shapes, etc. If you don't have any in your area (look in the Yellow Pages under plastics suppliers), you might be able to find someone who works with fiberglass that would have the equipment, etc.

Send your message to us

Plastic Sheets - High Density White 18mm PVC Foam Board for Furniture Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords