Plywood 1/4 4x8 Finger Jointed Shuttering Plywood for Building Usage

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m³

- Supply Capability:

- 1000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

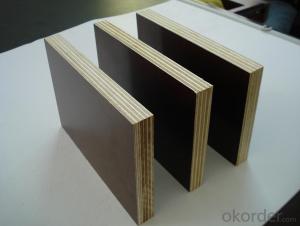

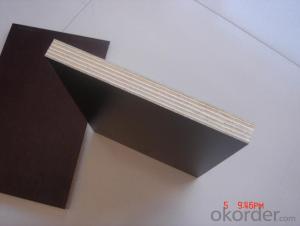

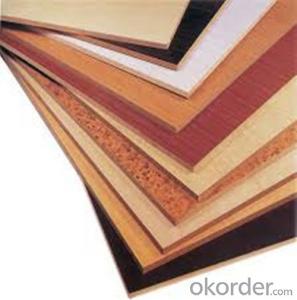

Core: Poplar/birch/combi/hardwood core

Glue: WBP/Melamine/MR

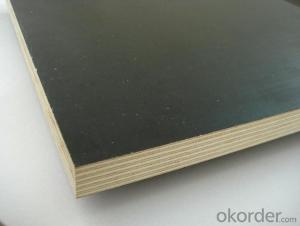

Film Color: Dark brown, black film. Other colors, like yellow, green, grey, can be specially ordered.

Thickness : 4 6.5 9 12 15 18 21 24 27 30 mm

Description:

| Size | 1220*2440mm,1500*3000mm,915*1830mm,1250*2500mm,the other size |

| Thickness | 4mm-30mm |

| Thickness tolerance | +/-0.8mm |

| Glue | MR/MELAMINE/WBP |

| Moisture | 8%-15% |

| Film | Domestic black film/ domestic brown film/ dynea brown film |

| Material | Poplar/combi/hardwood |

| Density | 530kg/m3 |

| Main market | America, canada, european, middle-east |

Features:

1) Sizes: 1,220mm x 2,440mm, 1,250mm x 2,500mm,1,200 x 2,400mm

2) Thickness: 9mm, 12mm, 15mm, 18mm, 21mm

3) Core: poplar core, birch core, Hardwood core, combi core

4) Glue: MR glue, WBP glue

5) Film: black color, imported brown film, Chinese brown film

6) It has advantages of smoothness, non-distortion, light weight, high intension and easy application

FAQ:

1)Payment term:T/T deposit,balance against shipping documents,L/C.

2)Samples:free samples as request

3)Quality control:professional QC teams to make sure goods quality

- Q: Class I resistant weather plywood Class II water resistant plywood

- slab molding (mixing resin and additives pavement), under hot pressure, so that cellulose and Hemicellulose and lignin plasticized to form a plate.

- Q: How do you choose plywood in plywood production?

- Another problem is the growing number of furniture produced by the panel, although these furniture, "cypress" and other grain appearance,

- Q: What is the best way to fix multi-layer plywood?

- The usual length and width specifications are: 1220 × 2440mm, while the thickness specifications are generally: 3,5,9,12,15,18 mm and so on

- Q: Furniture solid wood and plywood which is better? Such as bed `wardrobe` TV cabinet `table

- the difference between the process: multi-layer solid wood flooring will be a layer of each layer of scientific criss-cross, to eliminate internal stress, at present, its layers have grown from 7 to 9 layers, 11 layers

- Q: What are the processing defects of plywood?

- Warping warPing is generally a regular deformation, part or all of the surface of the plywood is curved.

- Q: Plywood in the decoration works how to use

- A group of veneers are usually in the direction of adjacent layers of wood grain perpendicular to the formation of each other, usually its table and the inner plate symmetrically arranged in the center layer or plate on both sides.

- Q: What are the advantages and disadvantages of plywood?

- Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood

- Q: Plywood in the processing of defects

- Separation delamination The separation of two adjacent veneers due to lack of glue or poor glue.

- Q: What is the plywood made of wood?

- Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood, and then made of adhesive glue from the three or more layers of plate-like material

Send your message to us

Plywood 1/4 4x8 Finger Jointed Shuttering Plywood for Building Usage

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m³

- Supply Capability:

- 1000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords