End Mill Re-sharpener X1 for Grinding 2/3/4 Flute End Mill

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Proudct Description

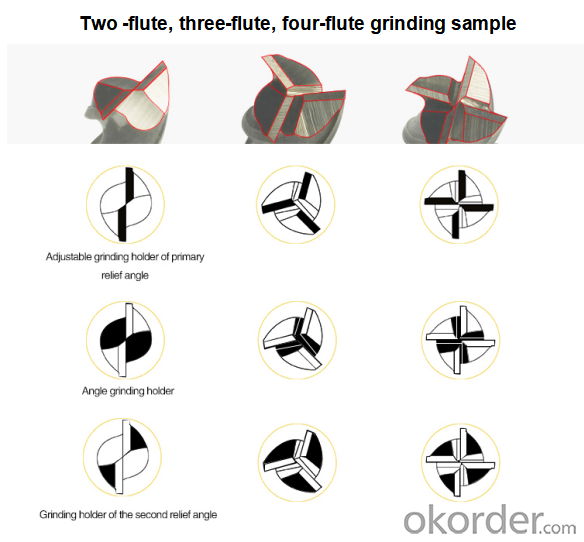

1. Portable end mill sharpener, can grind 2-flute, 3-flute, 4-flute end mill.

2. Grinding is accurate and rapid, easy operation with no skill to grind.

3. With Taiwan diamond grinding wheel, only one piece can complete all procedures.

4. Special chuck set, no need to adjust the slotting knob,you can complete the milling cutter long and short edge grinding.

5. Standard with SDC grinding wheel for the Carbide material, Optional CBN grinding wheel for the HSS material.

Standard equipments:

inner hexangular wrench:4(3mm、4mm、5mm、6mm)

Collet: 6 pcs(Φ4,Φ6,Φ8,Φ10,Φ12,Φ14)

Standard grinding wheel: SDC × 1 (for carbide)

Technical Parameters

Model: | TX-X1 |

Diameter: | Φ4-Φ14mm |

Power: | 220V/160W |

Speed: | 4400rpm |

Point angle: | 3° |

Dimension: | 35*25*25cm |

Weight: | 14KG |

Standard Equipment: | Grinding wheel :SDC (for carbide)×1 |

Six collets: Φ4,Φ6,Φ8,Φ10,Φ12,Φ14 | |

Two collet chucks 2,4 flutes ×1 piece 3,6 flutes×1 piece | |

Optional Equipment: | Grinding wheel :CBN (for HSS) |

Remarks:

1. The grinding wheel can be in metric or imperial system, which should be stated when ordering. The standard configuration is metric.

2. The factory is equipped with one type of 6mm (or 1\4″) collet, and other specifications are special accessories, which need to be specially ordered by users.

3. The motor can provide 380V\220V, 50Hz\60Hz according to user requirements.

Package

Q&A

Q1. Where is your factory located?

A : Our factory is located in Taizhou City, Zhejiang Province, China.

Q2. What is your MOQ of your machine?

A: Normally our MOQ is 1 set.

Q3. Do you test all your machine before delivery?

A: Yes, we have 100% test before delivery.

Q4: What is the payment term?

A: T/T 100% payment. We'll show you the photos of the products and packages before shipping.

Q5: What is the normal lead time?

A: If in stock, it usually takes10-15 days. 20-30 days if not in stock, depending on quantity.

Q6: Guarantee Period?

A: 1 year only for motor.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

End Mill Re-sharpener X1 for Grinding 2/3/4 Flute End Mill

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products