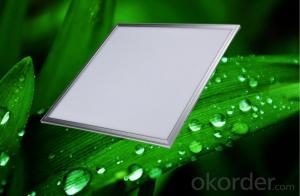

Dimmable LED Panel Light Square SMD Chip 9W

- Loading Port:

- Shenzhen

- Payment Terms:

- TT

- Min Order Qty:

- 10 Pcs pc

- Supply Capability:

- 20000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Dimmable LED Panel Light Square SMD Chip 9W

Features:1.Can replace traditional LED tube lights, no need for ballast and starter, reducing the rate of failure;2. Turn on the light immediately, no flicker and no delay, no high-frequency noise;3. Aluminum housing, resistant to damage and excellent heat dissipation, and recyclable;4. Wide Voltage range, can work under low voltage, the brightness will not change with voltage fluctuation;5. Great color rendering, color presentation is more realistic, more vivid, better light definition;6. Long lifetime, lifespan is more than 50,000 hours;7. Eco-friendly, No pollution of Lead and Mercury, Lower energy consumption and pollutants eliminated;8.High luminous efficiency, save 60% electricity bill compared to traditional tube light.

Applications:1.Hotels, Conference, Meeting rooms2.Factories & Offices3.Commercial Purposes4.Residential/institution Buildings5.Schools, Colleges & Universities, Hospitals6.Other lighting use

- Q: How is the indoor installation of the LED panel lamp convenient?!

- 1, hanging: first in the LED panel lights back mounted on the suspension member, then connect the lanyard on it. Consumers must pay attention to ask, understand clearly hanging components is the manufacturer's standard parts or buy parts?.2, suction top type: first in the ceiling to play a few holes, and then LED panel light slide into the suction ceiling frame installed on the ceiling, fixed three sides. Then slide the panel light into it, and then screw the frame around the fourth edge. Convenient, simple and time-saving.3, embedded type: the first sheet metal groove is arranged on the ceiling, and then the bracket is fixed at the back of LED panel light pieces protruding outward, and then into the panel light, the sheet metal bracket and the ceiling of the anastomotic groove can be fixed on the ceiling. But because of the different thickness of the ceiling, it is necessary to adjust the height between the lamp face and the bracket, otherwise it will cause the LED panel lamp to be higher or lower than the ceiling surface. In general, suspension mounted LED panel lights are best for aquarium lighting, while ceiling mounted is the most common and easiest way to do so.

- Q: What are the accessories for the LED panel light?

- Lamp module, power supply, light guide plate, a diffusion plate, an external power supply, frame, screw these.

- Q: Decoration, living room and office, with LED tube or LED panel light?

- From the brightness uniformity, the LED flat panel lamp is good, and the LED tube is high from luminous efficiency,Install the LED panel in the office.

- Q: What is the structure of the smart LED panel lamp?

- Analyze the structure of LED panel light for landlord:LED panel light consists of outer frame (with fixed lamp body structure and heat dissipation function), PC cover (face mask), light guide plate(the divergence of light diffusion plate (uniform), the light diffusion), light (luminescence), sensor power (voltage and current to provide integrated control LED lamp required to open and close the cover (), heat, dust and foreign matter blocking etc.).The above components affect the quality of the lamp. Among them, light guide plate, light source and power supply drive are decisive factors. Of course, good heat dissipation is a direct impact on the service life of lamps.

- Q: What is the light source of the LED panel light?

- The LED panel light source is the LED chip. It is placed on the 2 side of the panel light, and the light is uniformly distributed to the whole light surface through the light guide plate on the back

- Q: What is the light guide panel of the LED panel lamp?

- The optical grade acrylic plate as basic raw materials, and then use the LCD panel and the backlight module of notebook computer display technology, through the light guiding points full of high light transmittance, the PC distribution guide dot design makes the LED panel light guide plate parts light converted into surface light source are light design and manufacture after molding.1, the light guide plate (light guide plate) is the use of optical grade /PC acrylic sheet, and then use high-tech materials with high reflectivity and absorption of light, the optical grade acrylic bottom with UV screen printed guide dot printing technology. The use of optical grade acrylic sheet drawing out the lights stay in optical grade acrylic sheet surface, when the light guide to each spot, the reflected light will spread to all angles, and then destroy the reflection condition by the light guide plate is injection.2, through the various density, different sizes of light guide point, can make the light guide plate uniform luminescence. The purpose of the reflector is to reflect the light exposed on the bottom back into the light guide plate to improve the use efficiency of the light. Under the same area of illumination, the luminous efficiency is high and the power consumption is low. Single side micro array light guide plate is usually made by injection molding.

- Q: What material does the LED panel light need, such as the light guide plate or something?

- The light guide plate (light guide plate) is the use of optical grade /PC acrylic sheet, and then use high-tech materials with high reflectivity and absorption of light, the optical grade acrylic bottom with UV screen printed guide dot printing technology. The use of optical grade acrylic sheet drawing out the lights stay in optical grade acrylic sheet surface, when the light guide to each spot, the reflected light will spread to all angles, and then destroy the reflection condition by the light guide plate is injection.

- Q: How to install the LED panel lamp, is there a installation instruction?

- Stent typeFirst, make a few holes in the ceiling, then slide the LED panel light into the suction ceiling and install it on the ceiling. Fix the three sides. Then, turn the panel light into the fixed slide mounting box, slide in, and then fix the frame with the screws on the fourth edge. Convenient, simple and time-saving.

- Q: How many watts is the LED panel light?

- According to size, generally 4 inches in 10W or so, 6 inches in 20W or so, 8 inches in 25W or so

- Q: How many power LED panel lights are selected in the kitchen?

- Kitchen is not big, then 10W almost, it is recommended to buy good quality, do not buy too much water, or later will be very troublesome.

1. Manufacturer Overview

| Location | Shenzhen,China |

| Year Established | 2011 |

| Annual Output Value | |

| Main Markets | Mid East;Western Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen |

| Export Percentage | |

| No.of Employees in Trade Department | 20 People |

| Language Spoken: | Chinese |

| b) Factory Information | |

| Factory Size: | Above 4,000 square meters |

| No. of Production Lines | About 6 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Cheap |

Send your message to us

Dimmable LED Panel Light Square SMD Chip 9W

- Loading Port:

- Shenzhen

- Payment Terms:

- TT

- Min Order Qty:

- 10 Pcs pc

- Supply Capability:

- 20000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords