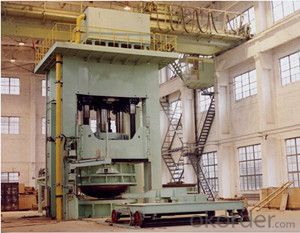

die forging hydraulic presses and isothermal die forging hydraulic presses

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TYHI designs and manufactures common die forging hydraulic presses with various specifications, such as multidirectional die forging hydraulic presses and isothermal die forging hydraulic presses and others per customers’ requirements.

Our main products include lifting equipment, forging equipment, rolling equipment, excavation equipment, coke oven equipment, coal chemical equipment, wind power generating equipment, oil film bearings for rolling mills, gear drive equipment, train wheels and axles, forgings and castings and project contracting.

Our key products include our 1200t EOT crane, our 500t ladle crane, our 75m³ shovel for mining, our Φ180mm continuous rolling production line, our 110 MN aluminum alloy extrusion press and our 7m top charging coke oven equipment.

TYHI’s products are widely used in the metallurgical, mining, energy, transportation, aerospace, chemical, rail, ship building, environmental protection and various other industries. Many products designed and manufactured by TYHI have filled gaps in the domestic market. Furthermore, we have created 360 nationally and internationally recognized products which have been exported to approximately forty countries and regions.

TYHI is now delving further into the development of the rail, engineering machinery, new energy, and maritime equipment fields. We have established a new production base in the Binhai New Area of Tianjin to facilitate the transportation and export of large-sized equipment. Our second wheel production line is currently under construction. We have also established production lines for wheels, axles and wheel sets for use at speeds above 200 km/h.

We are now turning our focus to international markets which we are certain can benefit from our high quality products and service. As we are constantly innovating and improving, we have no doubt that we will meet and even exceed our customers’ expectations.

- Q: Safety induction device for punching machine in production

- The principle of punching machine is driven by the motor flywheel, and through the clutch, transmission gear drive crank connecting rod mechanism to move up and down the slider, driven by the mold on the steel plate molding.

- Q: The word punch how to make sentences

- Huge dynamic stresses can occur in structures such as bridges, inverted siphons, machine bases, presses and so on.

- Q: How to distinguish between stamping machine installed mold to pad pad it?

- in order to take the red down the parts, but also need to add a hammer under the mold, the mold pad up overhead

- Q: What is the relationship between the pressure of the punching machine and the air pressure?

- The pressure change of the balancer is generally 1.2 times

- Q: 400t punching machine table size

- 400 tons of punch There are several types, there are open single point, open double and closed single point and closed double point, etc., the current closed punch, mainly for the Longmen steel welding the whole body, do the traditional three

- Q: Why do you want to install a large flywheel on a punching machine?

- This allows a smaller motor (driving force) to solve the need for greater energy at the moment of punching the workpiece.

- Q: How does this door's profile come out? The

- First of all, according to the user given the drawings or the proposed style (with the style of the production);

- Q: Punching machine and hydraulic press the difference and characteristics of what

- The difference between the two is still a lot, specifically as follows

- Q: The number of tons of automotive stamping machine?

- Some small, such as fine red parts of the safety parts are about 1,000 tons

- Q: Thick PE material after the deformation of the punch how to do

- I was PE foam, is rushed to the knife mold inside has been deformed, (30mm thick soft PE foam)

Send your message to us

die forging hydraulic presses and isothermal die forging hydraulic presses

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords