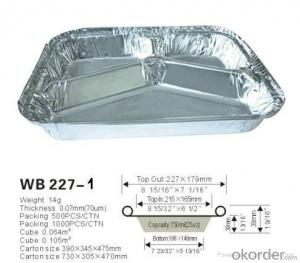

Continours Casting Aluminium Foil Household Foil Aluminium Containers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Metalized film roll for food packing/ foil laminated roll film & foil roll film

1.10 years manufacturer for packaging bag

2.We have professional designer

3.Free sample and short delivery time

4.FDA,SGS,QS

5.Gavure printing, up to 10 colors

Specifications

pet food packing film

1.20 years OEM service, custom order available

2.Excellent barrier

3.FDA, SGS

1,food grade for food packing,eco-friendly ink,smell proof,tasteless,non crack.,Good barrier against moisture, oxygen, puncturing and light ray;

2,easy to open and reclose

3,The bags can be made of different material to suit for package of different products: BOPP/CPP/NY/PET/PA/AL/VMPET/PE/LDPE laminated material

4,keep bag inside products clear and fresh,

5,Various colors, sizes and designs according to customers' requirements

6,beautiful color printing and good laminating

7,advanced high speed machine and good technical staff.

Our services

1. Reasonable production arrangement to make delivery very fast;

2. We are able to provide leading tolerances, metallurgical assistance, quick and reliable delivery, samples for new products, etc.

3.We have the strong capability to meet your particular requirement for the products.

4.To guarantee the quality of the products we can meet most of the standards all over the world.

- Q: The working principle and characteristics of hand held aluminum foil sealing machine

- 1. Choose the flat surface, steady the machine, insert the joint of the inductive head into the socket on the front panel of the machine and screw it tightly. Pay attention to the orientation of the socket.2. One end of the plug of the power cord is inserted into the power supply socket on the rear plate of the machine case, and the other end is inserted into the power supply socket, and the single-phase three wire power supply must be used. Voltage 220V, socket can withstand more than 10A current.3. Turn on the power switch on the rear panel of the cabinet. The sealing time of the control panel is bright and the machine can work.4, press and hold the time setting button, according to the need to seal the diameter of the container, material set a suitable value, setting value between 0.1-3.9 seconds.5, the container alignment of the sensor head of the center (previously placed induction aluminum foil container cover and tighten the membrane compaction) by induction power switch on the handle, then the original set time countdown to zero, said the work has been completed, and then remove the sensor head container under a sealing operation.6, check the sealing quality, according to different materials, diameter containers, as well as production efficiency, appropriate trimming time setting button, so that the sealing quality to the best.7, do not work, press the power switch on the front panel closed.

- Q: Relationship between capacitor capacity and aluminum foil

- The dielectric constant is determined by the medium between the two platesIf the aluminum electrolytic capacitor, because the medium is AL2O3, the medium is very thin, if the voltage under certain conditions, the greater the aluminum foil area, the capacity is about large, so the capacity is basically determined by the area of aluminum foil!

- Q: What is the difference between metallized capacitor and metal film capacitor?

- Metallized film capacitor is a metallized film capacitor that is rolled or laminated with a double-sided metallized polypropylene film and a non - metallized polypropylene film

- Q: The difference between aluminium foil alloy 1060 and 1235

- Our company rolled aluminum foil. The raw material is 0.3mm aluminum alloy strip of A1235 or A8079 alloy, rolled by 4~5 passes and rolled into 5.5~8um aluminum foil.

- Q: Is there any harm to the pure milk packing aluminum foil in boiling water?

- As the soft packaging materials, it is in order for us to buy and carry, and is not used as a heating container, so consumers should Hot Milk when drinking or recommend it from this bag onto the glass, or kitchen use high-temperature beaker, containing the aluminum foil packaging milk is absolutely not to heating with microwave oven. In addition, over heating milk also has an impact on nutrition.

- Q: How aseptic packaging aluminum foil bags?

- Foil bag has many advantages over other traditional packaging materials (such as difficult to have superior performance, molding, convenient use, low cost, etc.) as one of the plastic packaging materials, which plays a great role in the development of aluminum foil bag, along with other traditional packaging materials incomparable speed.

- Q: What's the flow of aluminum foil statistics?

- A brief history of aluminum foil production has been one hundred years old. In 1890, Germany (F RTH) fvrth in Nuremberg workshop, by hand hammering produce a piece of aluminum foil. In 1905 the Swiss industrialist Gao Qi (A.Gautsh) and Yagule (Jaguler) with block roll thickness flake aluminum foil 0.05mm. In 1910, Nerel, Switzerland (R.V.Nehrer) and others rolled aluminum foil with rolling tape method to make aluminum foil enter the stage of industrialization. At that time, the use of two high mill, rolling speed is only 10 to 20m / min, the volume weight of not more than 50kg.

- Q: What are the specifications and uses of common aluminum foil?

- Paper foilAlloy status: 1235-O, 8079-OTypical thickness: 0.006Processing methods: aluminum paper compositeEnd use: barrier and aesthetic effect.

- Q: Does the disposable aluminum foil lunch box affect your health?

- Aluminum foil used as a food container has the characteristics of safety, health, high and low temperature resistance, green environmental protection, regeneration, energy saving, good sealing and so on.

- Q: Hand held aluminum foil induction sealing machine, how long is the sealing time?

- Handheld aluminum foil sealing machine use environment:Handheld foil sealing machine maximum ambient temperature 45 degrees centigrade, relative humidity not higher than 80%, the machine should be placed in a well ventilated environment, cooling hole induction power supply side and bottom heat radiating holes and inductive head to ensure clean and smooth. Excessive temperature or humidity will have a great impact on the life of electronic components, and even lead to damage to the equipment.

Send your message to us

Continours Casting Aluminium Foil Household Foil Aluminium Containers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords