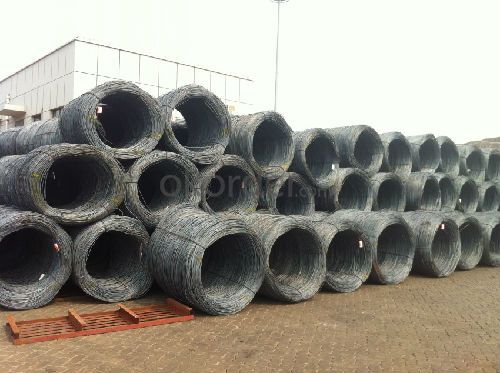

Carbon Steel Hot Rolled Wire Rod in Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Wire Rod at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

After hot-rolled the products shaped into coil and delivery as finished product, including round, square, rectangular, hexagonal and so on. Since most of the products are round, it is generally called wire rod. Carbon steel wire rod is widely used in construction and manufacturing. Carbon steel wire rod is mainly used for reinforcement of reinforced concrete and welded structure or reprocessed (roberts , nail, etc.) materials, especially used to produce wire drawing, welding electrode, nails, spring, electronic, precise machinery parts and so on.

Product Advantages:

OKorder's Wire Rod are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Steel Grade: Q195/235, SAE1006-1018B Standard: ASTM, GB

Diameter: 5.5mm, 6.5mm, 7mm,8mm,9mm,10mm,12mm,14mm

Type: in coil, coil weight around 2MT Alloy or Not: Alloy

Surface: round, no twisted, light and smooth Chemical Composition: (Please kindly find our chemistry of our material based on Q195、Q235A and Q235B as below for your information)

Grade | Chemical Composition (%) | |||||

C | Mn | S | P | Si | B | |

SAE1008B | 0.10max | 0.32max | 0.045max | 0.040max | 0.30max | 0.0008min |

Mechanical properties | ||||||

Yield strength(N/mm2) | Tensile strength(N/mm2) | Elongation (%) | ||||

≥195 | 350-380 | ≥32 | ||||

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard carbon steel wire rod we can supply:

Grade: H08A, 30MnSi, 62B-82B

Standard: AISI, BS, JIS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply carbon steel wire rod; if you need anything about building materials, please contact us.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

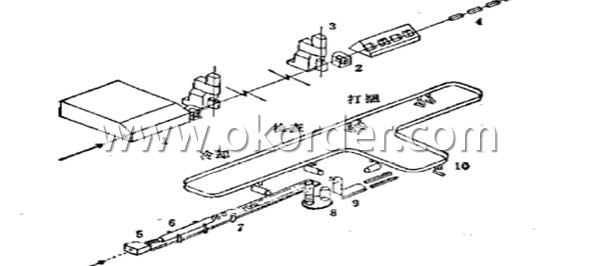

1-Furnace 2-Roughing Mill 3-High-speed Finishing Mill 4-Water-cooled Device 5-Coiling Device

6-Cooling Device 7-Chain Conveyer 8-Spool Collecting Device 9-Spool Down Device 10-Hook Conveyer

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: What are the main factors influencing the choice of steel wire rod coating?

- The main factors influencing the choice of steel wire rod coating include the intended application, environmental conditions, durability requirements, and cost considerations. Firstly, the intended application of the steel wire rod is crucial in determining the appropriate coating. Different coatings provide specific properties such as corrosion resistance, lubricity, or electrical conductivity. For example, if the steel wire rod is intended for outdoor use or exposure to moisture, a corrosion-resistant coating such as zinc or zinc-aluminum is preferred. On the other hand, if the wire rod is used for electrical purposes, a coating with high electrical conductivity may be necessary. Secondly, the environmental conditions in which the steel wire rod will be used also play a significant role in the choice of coating. Factors like temperature, humidity, exposure to chemicals, and UV radiation can impact the performance and durability of the coating. Therefore, coatings that offer excellent resistance to these environmental factors are often selected. Durability requirements are another influential factor. Depending on the intended lifespan of the wire rod and the level of wear and tear it will experience, different coatings with varying levels of durability may be chosen. Some coatings, such as epoxy or polyurethane, provide excellent resistance to abrasion and impact, making them suitable for applications that involve frequent handling or rough environments. Lastly, cost considerations are an important factor in the choice of steel wire rod coating. Different coatings have different price points, and the cost must be balanced with the desired performance and durability. It is essential to choose a coating that meets the requirements at a reasonable cost, ensuring a cost-effective solution without compromising the performance of the wire rod. In conclusion, the choice of steel wire rod coating is influenced by the intended application, environmental conditions, durability requirements, and cost considerations. By considering these factors, manufacturers can select the most suitable coating that provides the necessary properties and durability for the specific application while being cost-effective.

- Q: How is steel wire rod used in the manufacturing of wire forms for signage?

- Steel wire rod is an essential component in the manufacturing process of wire forms for signage. The wire rod acts as the raw material from which wire forms are shaped and designed. Firstly, the steel wire rod is carefully selected based on its specific mechanical and chemical properties, such as tensile strength and corrosion resistance. These properties ensure that the wire forms produced using the rod will be durable and able to withstand various weather conditions. Next, the steel wire rod is processed through a series of manufacturing steps. The rod is typically drawn through a series of dies to reduce its diameter and increase its length. This process, known as wire drawing, allows for the production of wires with precise dimensions and smooth surfaces. Once the wire has been drawn to the desired thickness, it is then further processed to create specific shapes and forms required for signage. This can involve bending, coiling, or welding the wire into different configurations, depending on the design specifications. The wire forms created from steel wire rod are then utilized in the manufacturing of signage. These wire forms are commonly used as a structural framework or support for various types of signage, such as letters, logos, or decorative elements. The wire forms provide the necessary stability and rigidity to hold the signage in place, ensuring that it remains intact and visible. Moreover, the versatility of steel wire rod allows for the creation of intricate and complex wire forms, which can be customized to meet specific design requirements. This flexibility in design allows for the production of unique and eye-catching signage, enhancing visual appeal and brand recognition. In conclusion, steel wire rod plays a critical role in the manufacturing of wire forms for signage. It serves as the raw material from which wire forms are shaped, providing the necessary strength and durability required for signage applications. The ability to customize wire forms allows for the creation of visually appealing and distinctive signage, making steel wire rod an essential component in the signage industry.

- Q: What are the main challenges faced by the steel wire rod industry?

- The main challenges faced by the steel wire rod industry include intense competition from alternative materials, fluctuations in raw material prices, increasing energy costs, stringent environmental regulations, and the need for continuous technological advancements to meet evolving customer demands. Additionally, global economic conditions and trade disputes can also impact the industry's growth and profitability.

- Q: How are steel wire rods used in the manufacturing of wire baskets?

- Wire baskets rely heavily on steel wire rods as a vital element in their manufacturing process. These rods play a foundational and structural role in the construction of the baskets. They are typically crafted from high-quality steel, which imparts strength, durability, and resistance to corrosion. When incorporating steel wire rods into the production of wire baskets, the first step entails cutting them to the desired lengths. These lengths can vary depending on the specific size and design requirements of the basket. After being cut, the rods are then shaped into the appropriate form, be it square, round, or rectangular, in accordance with the basket's particular specifications. To assemble the wire basket, the shaped steel wire rods are either interwoven or welded together. This process creates a robust, mesh-like pattern that forms the body of the basket. The interlocking of the wire rods ensures the structural integrity of the basket while allowing for proper ventilation and visibility. The steel wire rods used in wire basket manufacturing can also undergo coating or treatment to enhance their properties. For instance, they can be galvanized to provide a protective layer against rust and corrosion, making the basket suitable for outdoor use or in humid environments. Additionally, the rods can be coated with plastic or vinyl, serving the dual purpose of adding color and preventing scratching or damage to the items stored in the basket. In conclusion, steel wire rods hold immense significance in the manufacturing process of wire baskets as they offer the essential strength and structure required for these versatile storage solutions. Their versatility allows for customization in terms of size, shape, and coating, making wire baskets suitable for an extensive range of applications across various industries, including retail, agriculture, and transportation.

- Q: What are the common production processes for helium-coated steel wire rod?

- The common production processes for helium-coated steel wire rod include the following steps: 1. Cleaning the steel wire rod to remove any impurities or contaminants. 2. Coating the wire rod with a layer of helium gas using a specialized coating machine. 3. Ensuring proper adhesion of the helium gas to the wire rod surface through a curing or drying process. 4. Inspecting the coated wire rod for any defects or irregularities. 5. Packaging and storing the helium-coated steel wire rod for further use or distribution.

- Q: How is steel wire rod processed to achieve desired properties?

- Steel wire rod is processed through a series of steps to achieve the desired properties. The first step is the melting of raw materials such as iron ore, coal, and limestone in a blast furnace. This process removes impurities and produces molten iron. The molten iron is then converted into steel through the basic oxygen furnace (BOF) or electric arc furnace (EAF) process. In the BOF process, oxygen is blown into the molten iron to remove carbon and other impurities, while in the EAF process, an electric arc is used to melt scrap steel. Once the steel is produced, it is cast into billets or blooms, which are semi-finished forms of steel. These billets or blooms are then hot rolled to reduce their size and shape them into wire rod form. Hot rolling involves passing the steel through a series of rollers that apply pressure and heat to shape the material. After hot rolling, the wire rod is cooled and then undergoes a process called pickling, where it is immersed in an acid solution to remove scale and impurities from the surface. This step helps improve the surface quality of the wire rod. Next, the wire rod is cold drawn through a series of dies to reduce its diameter and increase its strength. Cold drawing involves pulling the wire rod through progressively smaller dies, which elongates and work-hardens the material. To achieve the desired properties, the wire rod may undergo additional processes such as heat treatment. Heat treatment involves heating the wire rod to a specific temperature and then cooling it rapidly or slowly to modify its microstructure and improve its mechanical properties. Finally, the wire rod is typically coated with a protective layer or surface treatment to enhance its corrosion resistance and improve its surface finish. Common coatings include zinc, phosphate, or polymer coatings. Overall, the processing of steel wire rod involves a combination of melting, casting, rolling, pickling, cold drawing, heat treatment, and coating processes to achieve the desired properties such as strength, ductility, surface finish, and corrosion resistance.

- Q: What are the current trends in the steel wire rod market?

- The current trends in the steel wire rod market include increasing demand from the construction and automotive sectors, growing preference for high-quality and sustainable steel products, and advancements in technology leading to enhanced production efficiency and product performance. Additionally, there is a shift towards lightweight materials in various industries, which is driving the demand for steel wire rods with superior strength and flexibility.

- Q: How are steel wire rods used in the automotive industry?

- The automotive industry widely employs steel wire rods for various purposes. One of their main uses is in the production of suspension systems, where they are utilized to create crucial components like coil springs, torsion bars, and stabilizer bars. These components play a vital role in ensuring the vehicle's stability and providing a smooth ride. Steel wire rods are also extensively used in the manufacturing of automotive tires. They serve as reinforcement materials for the tire belts, adding strength and durability. These wire rods are typically embedded in the rubber, enhancing the overall structural integrity and resistance to wear and tear. Furthermore, steel wire rods are an essential part of seat frames and seat belts. They form the framework of the seats, offering support and stability to the occupants. In seat belts, the wire rods are utilized as the inner structure, ensuring strength and the ability to withstand impacts during collisions. Moreover, automotive springs, such as those used in the suspension system, clutch, brakes, and seat mechanisms, are made from steel wire rods. These wire rods are coiled to provide the necessary elasticity and resilience required for these components to function effectively. Additionally, steel wire rods are employed in the production of automotive cables. These cables transmit power and signals to various parts of the vehicle, including the accelerator, brakes, and clutch. The wire rods serve as the inner core of these cables, ensuring their strength and durability. In conclusion, steel wire rods have extensive applications in the automotive industry. They are used in suspension systems, tire manufacturing, seat frames, seat belts, springs, and cables. The utilization of steel wire rods in these components greatly enhances the overall performance, safety, and reliability of vehicles.

- Q: What are the different packaging options available for steel wire rod?

- There are several different packaging options available for steel wire rods, depending on the specific requirements and preferences of the customers. Some of the common packaging options include: 1. Coils: Steel wire rods can be packaged in coil form, where the rod is wound into a circular shape. Coils are commonly used for smaller diameter wire rods and are often wrapped in plastic or paper to protect them from corrosion and damage during transportation. 2. Bundles: Larger diameter steel wire rods are often packaged in bundles. In this packaging option, multiple rods are tied together using straps or wire and wrapped in protective materials such as plastic or paper. Bundles allow for easy handling and transportation of the wire rods. 3. Pallets: Steel wire rods can also be packaged on pallets, particularly when large quantities are being shipped. The rods are arranged on a wooden or plastic pallet and secured using straps or stretch film. Pallets provide stability and ease of storage and handling. 4. Reels: For specific applications, steel wire rods may be packaged on reels. This packaging option is commonly used for wire rods that are intended for use in the manufacturing of cables or wires. The rods are wound onto a reel, which can be made of wood, plastic, or metal, and often come with flanges to prevent tangling. 5. Customized Packaging: In some cases, customers may require customized packaging options for their steel wire rods. This can include specific labeling, marking, or additional protective measures to meet their specific needs. Manufacturers and suppliers can work with customers to develop tailored packaging solutions. Overall, the choice of packaging option for steel wire rods depends on factors such as the diameter of the rods, the quantity being shipped, and the specific requirements of the customers. Manufacturers and suppliers can provide guidance and recommendations based on their expertise and experience in the industry.

- Q: What are the factors that affect the corrosion resistance of steel wire rod?

- There are several factors that can affect the corrosion resistance of steel wire rod. Firstly, the composition of the steel is a significant factor. Different alloying elements can alter the corrosion resistance of steel wire rod. For example, the addition of chromium and nickel in stainless steel enhances its resistance to corrosion. Secondly, the surface condition of the steel wire rod plays a crucial role. If the surface is rough or contains impurities, it can provide sites for corrosion initiation. In contrast, a smooth and clean surface can inhibit corrosion. Thirdly, environmental conditions can greatly impact the corrosion resistance of steel wire rod. Factors such as humidity, temperature, and the presence of corrosive substances like acids or salts can accelerate corrosion. Exposure to marine environments or industrial atmospheres with high levels of pollutants can also increase the likelihood of corrosion. Furthermore, the protective coatings applied to steel wire rod can greatly enhance its corrosion resistance. Coatings like zinc or epoxy can act as a barrier against corrosive agents, preventing them from reaching the surface of the steel. Lastly, the presence of mechanical stress or strain can influence the corrosion resistance of steel wire rod. Stress concentrations or deformation can create microcracks or expose vulnerable areas, leading to localized corrosion. In conclusion, the corrosion resistance of steel wire rod is influenced by factors such as alloy composition, surface condition, environmental conditions, protective coatings, and mechanical stress. Understanding and controlling these factors are crucial for ensuring the longevity and reliability of steel wire rod in various applications.

Send your message to us

Carbon Steel Hot Rolled Wire Rod in Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords