Plastic Film For Masking In Auto Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 30000 roll/month

- Option:

- Plastic Film

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Plastic Film For Masking In Auto Industry

1. Structure of Masking Film Description

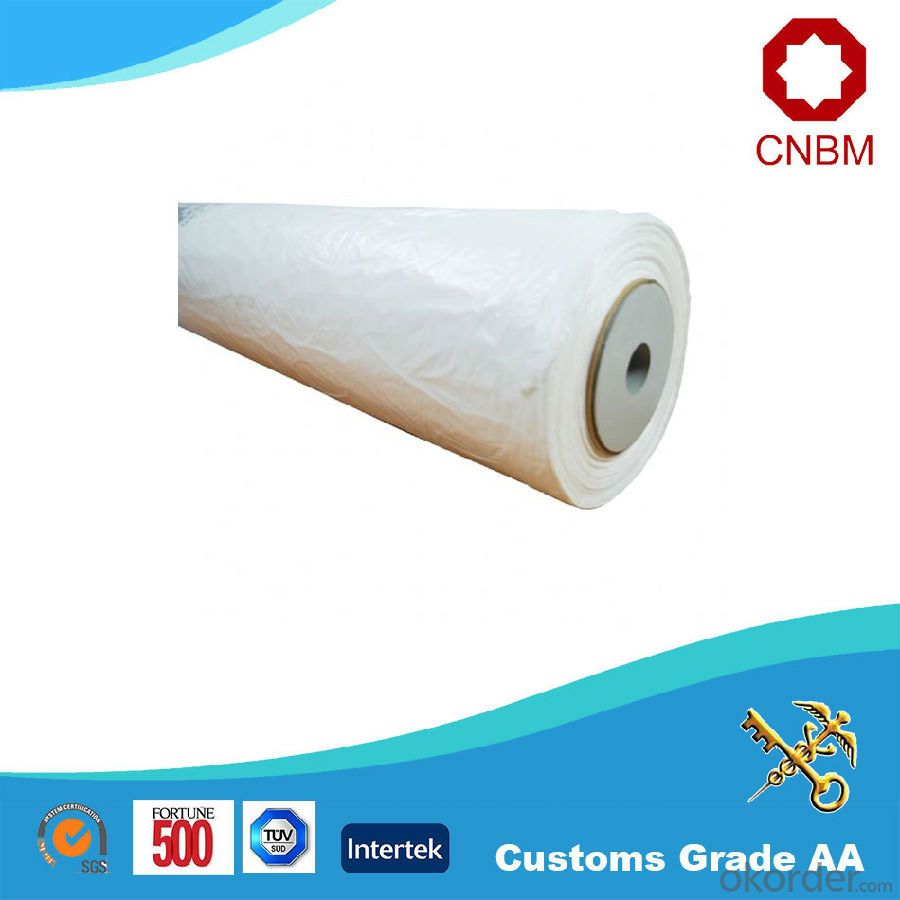

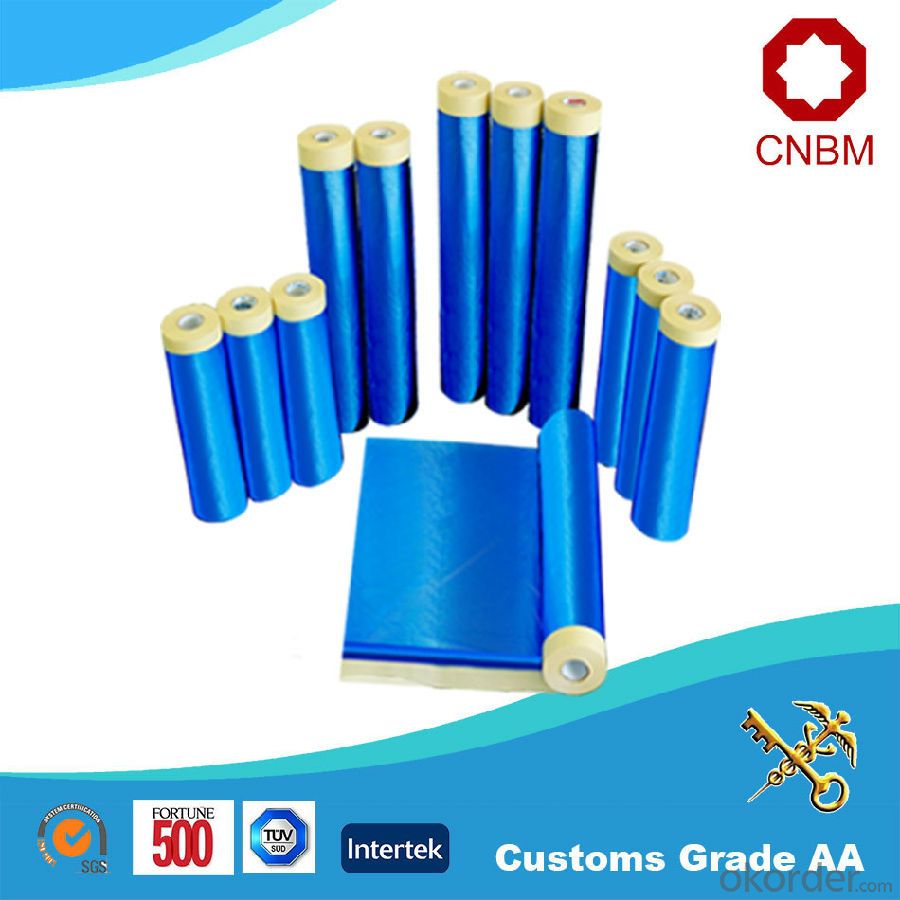

Masking Film is of HDPE film and masking tape. A convenient, pretaped plastic film which unfolds to cover and protect various surfaces while painting. Specially treated film clings to surfaces and is easy to clean up.

2. Main Features of Masking Film

Multi-Folded easy to use;

Strong and Flexible;

Competitive price

Indoor/outdoor painting

Sunlight stable even on glass

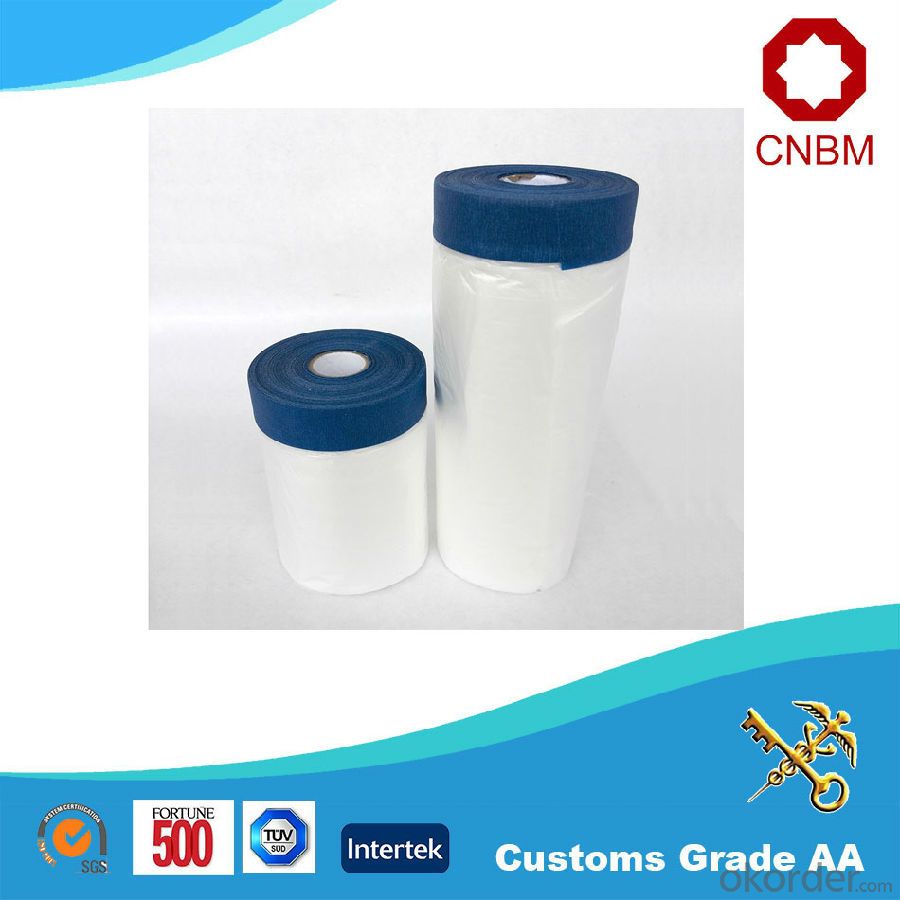

3. Masking Film Images

4. Masking Film Specification

Tape Size | Rolls/Carton | Weight/Roll(kg) | Jointing Material | Temperature Resistance |

330mm*30M | 20 | 0.12 | Crepe parer | -5—60°C |

550mm*30M | 50 | 0.17 | Crepe parer | -5—60°C |

1100mm*30M | 25 | 0.30 | Crepe parer | -5—60°C |

1400mm*30M | 10 | 0.39 | Crepe parer | -5—60°C |

5. FAQ

Q1. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

Q2.Why choose us?

20 Years Experience USD1.6 billion yearly sales

World Top 500 Enterprise

OEM service, supported by strong R&D team

A short lead time

Quality guarantee with third party certification

One-step service: transportation, capital etc.

Q3. How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:Is packaging tape heat resistant?

- Yes, packaging tape is generally heat resistant. Most packaging tapes are made from materials such as polypropylene or acrylic, which have high melting points and are able to withstand high temperatures. This heat resistance makes packaging tape suitable for various applications, including sealing boxes and packages that may be subjected to heat during transportation or storage. However, it is important to note that the specific heat resistance of packaging tape may vary depending on the brand and quality of the tape. Therefore, it is recommended to check the product specifications or consult with the manufacturer to ensure that the packaging tape is suitable for the intended use and temperature conditions.

- Q:Can packaging tape be used for sealing cosmetic or beauty products?

- Yes, packaging tape can be used for sealing cosmetic or beauty products. However, it is not the ideal choice as it may not provide the aesthetic appeal and professional finish that specialized packaging materials designed for beauty products offer.

- Q:Is packaging tape safe to use on plastic picture frames?

- Yes, packaging tape is generally safe to use on plastic picture frames. Packaging tape is designed to be strong and durable, making it suitable for securing items, including plastic frames. However, it is important to consider a few factors before using packaging tape on plastic picture frames. Firstly, ensure that the tape does not have any adhesive that could potentially damage or leave residue on the frame. It is advisable to test a small, inconspicuous area of the frame with the tape before applying it to the entire frame. Additionally, when removing the tape, do so carefully to avoid any potential damage to the frame. Overall, as long as you exercise caution and choose an appropriate tape, packaging tape should be safe to use on plastic picture frames.

- Q:What are the considerations for using packaging tape on textured surfaces?

- When using packaging tape on textured surfaces, there are a few considerations to keep in mind. Firstly, the texture of the surface can affect the adhesion of the tape. Textured surfaces typically have uneven or rough areas, which may make it difficult for the tape to adhere securely. It is important to choose a packaging tape that is specifically designed for textured surfaces. These tapes usually have a stronger adhesive that can better stick to uneven surfaces, ensuring that the tape will stay in place. Another consideration is the durability of the tape. Textured surfaces can be more abrasive than smooth surfaces, which can cause the tape to wear out more quickly. It is important to select a packaging tape that is made from a durable material, such as reinforced or heavy-duty tape. These types of tape are designed to withstand more wear and tear, providing a longer-lasting bond on textured surfaces. Additionally, the texture of the surface can also affect the appearance of the tape. Since textured surfaces are not smooth, the tape may not lay flat and can create air pockets or wrinkles. This can make the package look untidy or unprofessional. To improve the appearance, it may be necessary to use extra tape or apply it in a way that smooths out any unevenness. Lastly, it is important to consider the removal of the tape from textured surfaces. Textured surfaces can make it more difficult to remove the tape cleanly without leaving behind any residue. To prevent damage to the surface or any sticky residue, it is recommended to test the tape on a small, inconspicuous area before fully applying it. If the tape does leave residue, there are adhesive removers available that can help safely remove any remaining residue. In summary, when using packaging tape on textured surfaces, it is important to choose a tape specifically designed for uneven surfaces, select a durable tape that can withstand the texture, consider the appearance of the tape on the textured surface, and be cautious of any potential residue left behind when removing the tape.

- Q:What are the tapes for packing tape?

- There are many kinds: packing tape series: transparent adhesive tape, color adhesive tape

- Q:Can packaging tape be used for sealing office supplies or stationery?

- Certainly, office supplies or stationery can be sealed using packaging tape. This adhesive tape is highly versatile and frequently employed for sealing packages and boxes. Yet, it is crucial to take into account the size and weight of the item when using packaging tape for sealing smaller objects like office supplies or stationery. If the item is lightweight and the packaging tape is not excessively wide or bulky, it can serve as a convenient and effective option for sealing. Nevertheless, for smaller items, it might be more appropriate to utilize alternative types of tape, such as clear tape or double-sided tape, which are specifically designed for sealing stationery and office supplies.

- Q:Can packaging tape be used for sealing glass jars?

- Indeed, sealing glass jars is possible with packaging tape. However, it should be noted that packaging tape is not specifically designed for this purpose and more suitable alternatives are available. While packaging tape can offer a temporary seal, it may not be as effective in preserving the freshness and airtightness of the jar's contents. Furthermore, the tape may not adhere well to glass surfaces and could peel off over time, potentially compromising the seal. For optimal results in preserving the contents of glass jars, it is recommended to utilize specialized methods and materials such as rubber gaskets, metal lids with screw caps, or heat-sealing techniques.

- Q:Is packaging tape suitable for sealing heavy boxes?

- Yes, packaging tape is suitable for sealing heavy boxes.

- Q:What are the benefits of using UV-resistant packaging tape?

- UV-resistant packaging tape offers numerous advantages. Firstly, it is specifically designed to endure prolonged exposure to sunlight, preventing it from deteriorating or degrading. This is particularly crucial when shipping or storing items outdoors or in areas with direct sunlight. With UV-resistant tape, packages can remain securely sealed for extended periods as it maintains its adhesive properties and structural integrity. Furthermore, UV-resistant packaging tape safeguards the contents of packages from UV ray damage. Sunlight can cause materials like paper, fabrics, or plastics to fade, discolor, or degrade. By utilizing UV-resistant tape, these items are shielded from the harmful effects of UV rays, preserving their quality and appearance. Moreover, UV-resistant packaging tape boasts long-lasting adhesion. Unlike regular tape, which may lose its stickiness over time when exposed to sunlight, UV-resistant tape is specially formulated to bond tightly and securely to various surfaces. This reliable adhesion minimizes the risk of packages opening or items sustaining damage during transit. Additionally, UV-resistant packaging tape provides peace of mind for both senders and recipients. By opting for tape that is resistant to UV rays, businesses and individuals can ensure that their packages arrive in the same condition they were sent, enhancing their professional image and customer satisfaction. This advantage is particularly vital when shipping valuable or delicate items that require extra protection. In conclusion, UV-resistant packaging tape offers enhanced durability, protection against UV damage, long-lasting adhesion, and increased confidence in package integrity. By selecting UV-resistant tape, individuals and businesses can effectively safeguard their packages and their contents, even when exposed to prolonged sunlight.

- Q:What type of rubber tape and hot-melt tape?

- Application of duct tape 2, duct tape is mainly used for carton sealed, carpet seams together, heavy packing, waterproof packaging etc.. At present in the automotive industry, paper industry, mechanical and electrical industry also frequently used, for automobile cab, chassis, cabinets and other waterproof measures better place. Easy die cutting.3, tape tape according to different classification can be divided into hot melt glue, tape, rubber tape.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic Film For Masking In Auto Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 30000 roll/month

- Option:

- Plastic Film

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords