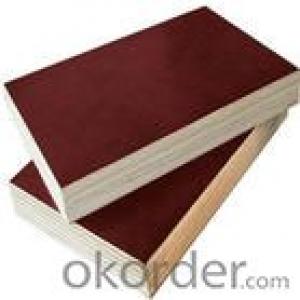

15mm Thickness Film Faced Plywood with Brown Color Film

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

15mm Thickness Film Faced Plywood with Brown Color Film

Product Description:

· Type: Film Faced Plywood

· Material: Wood

· Wood Style: Panel

· Panel Type: Plywood

· Use: Indoor

· Place of Origin: China (Mainland)

· Model Number: 1220x2440mm

Plywood is a wood product manufactured out of many sheets of veneer, or plies. And plywood is pressed together and glued, with their grains going in opposite directions. It is also referred to as an “engineered wood”, because it is made from the compound wooden materials, and formed various forms go through thousands of years.

Packaging & Delivery:

1. Packaging Details: inner packing:0.20mm plastic bag; outer packing: pallets are covered with plywood or carton and then steel for strength

2. Delivery Detail: within 15 days after receiving the deposit

Product Specification:

Detailed Product Description | ||

Features | Face/back | melamine /veneer/pvc/hpl/ev (As you required) |

Glue | E1 or E2 ... (As you please) | |

Size | 1220*2440mm or 1830*2440mm | |

Thickness | 2.0mm~35mm | |

Core | poplar, combi etc. | |

Moisture | normal, moisture-proof, water-proof, eco-friendly | |

Payment & Shipping | MOQ | 1*20' container (negotiable) |

Port | Qingdao | |

Packing details | Inter packing: 0.20mm plastic bag Outer packing: pallets are covered with plywood or carton and then steel for strength | |

Delivery time | Within 15~20 days after 30% deposit or L/C | |

Payment terms | L/C,T/T | |

Supply ability | 50*40' HQ per Month | |

Advantages | Guarantee of 2 years | |

Competitive price | ||

ECO- friendly—— E1 grade, CARB P2 certificated | ||

High quality and excellent workmanship | ||

Company Info:

OKorder.com is an online building materials trading platform funded by CNBM (listed 267th on Fortune Global 2014) and is operated by CNBM International. CNBM International has more than 20 years trading experience and has established close business relationships with clients from over 160 countries.

As of the end of 2000, CNBM has 492 member companies under management around the world, of which 5 were A-share listed holding companies and 2 were H-share listed. CNBM has total assets exceeded RMB 110 billion, and more than 100,000 employees.

CNBM is the largest comprehensive building material industrial group in China that integrates scientific research, manufacturing and logistics into one entity.

OKorder.com is an online building materials trading platform funded by CNBM (listed 267th on Fortune Global 2014) and is operated by CNBM International. CNBM International has more than 20 years trading experience and has established close business relationships with clients from over 160 countries.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: The thickness of the steel plate of the temporary space sandwich panel is generally thick

- Room sandwich plate of the steel plate is generally called: color plate, the thickness of the general 0.5 ~ 0.7mm.

- Q: Can polyurethane sandwich panels be used for cold storage?

- Polyurethane sandwich panels can be used to make cold storage, polyurethane sandwich panels are two-component liquid polyurethane AB material through the prefabricated production line. Polyurethane sandwich board in the polyurethane material is isocyanate and polyether as the main raw material, in the foaming agent, catalyst, flame retardants and other additives under the action of foam polymer. Polyurethane rigid foam is a new type of synthetic material with insulation and waterproof function, its thermal conductivity is low, only 0.022 ~ 0.024W / (m · Κ), equivalent to half of the extruded plate, is the thermal conductivity of all insulation materials lowest. Cold storage polyurethane insulation generally have two kinds of technology, one is the use of sandwich panel on-site stitching, and another process is the use of polyurethane spray coating on-site spraying foam, compared to the first process, the second process because it is on-site spraying foam Any seams, greatly avoid the phenomenon of hot and cold joints, insulation effect is better than the first process.

- Q: Solid wood sandwich board how much money a piece

- No-name card (no license) 50 ~ ~ 60 yuan a brand, but the quality of the general 70 ~ ~ 90 yuan a brand, brand products (real 3A) more than 120 yuan each! Hope to help you, please adopt

- Q: What are the thickness of the color steel sandwich board? Color steel sandwich panels: two layers of steel thickness of 0.6mm, the middle folder a layer of foam, a total thickness of several specifications?

- Color steel sandwich panel thickness generally have the following: 25mm 50mm 75mm 100mm 150mm 200mm which after the two kinds of thickness is generally used for cold storage. You said the foam (EPS) density of the points, generally: 4g 6g 8g 10g, Can be purchased according to their own needs!

- Q: Color steel sandwich panel thickness specifications are several

- Color steel plate, refers to the color coated steel plate, color coated steel plate is a kind of organic coating with steel plate. Color steel plate is divided into veneer, Caigang composite board, floor board and so on. Widely used in large public buildings, public buildings, activities board room, and integrated housing walls and roofs. The substrate of the color steel plate is a cold-rolled substrate, a hot-dip galvanizing substrate, and an electro-galvanized substrate. Coating types can be divided into polyester, silicon modified polyester, polyvinylidene fluoride and plastic sol. The surface condition of the color steel plate can be divided into coated board, embossed plate and printing plate. The color steel plate is widely used in the construction of household appliances and transportation industry. The construction industry is mainly used for steel industry, airport, warehouse and freezing industry. Commercial buildings of the roof walls and doors, etc., civil buildings using less color plate.

- Q: 2x8 foor joists above not supporting the roof

- no, you really don't supply enough info on the weight loads this will hold but you may need to add a steel plate between them, also you need to survey the area where the posts rest and determine if this is strong enough for the transfer of the weight load you are taking a dispersed load and turning it into a point load, I have seen large headers put in and the floor where the posts rest start to sag because that area wasn't strong enough to support the point load

- Q: Polyurethane sandwich panel system of fire resistance, the general can be how much you like 100 thick

- Internal use of B1 grade polyurethane foam core material, fire resistance and panel material. For example, both sides of the use of cement-type plate and other composite, you can achieve composite A-class. While the use of color composite plate on both sides of the sandwich panel can not achieve composite A-class.

- Q: Polyurethane sandwich panels in the polyurethane is what material, what are the benefits of industrial building materials should choose polyurethane?

- Polyurethane is a two-component AB material (isocyanate and combined polyether) mixed foam, is the thermal insulation material in the lowest thermal conductivity of 0.017 ~ 0.024 (thermal conductivity of the lower the better insulation). Polyurethane sandwich panels used in the filling process of polyurethane, pre-made pre-insulation board directly installed on-site use. If your plant area is relatively large, it is recommended that you only use the whole color plate, and then use the field of polyurethane spray foam process, this process than the infusion process is the advantage of spraying seamless, better insulation. The cost is still lower than the infusion process.

- Q: Use the foam color steel sandwich panel after decoration

- Paste the wallpaper, polystyrene foam board - also known as foam color steel sandwich panels, EPS board is containing volatile liquid blowing agent of the polystyrene beads, heated by heating in the mold after heating It is mainly used in building wall, roof insulation, composite board insulation, cold storage, air conditioning, vehicle, ship insulation, floor heating, decorative carving and other uses are very extensive. Wallpaper, also known as wallpaper, wall cloth, is a wall for the interior decoration materials, widely used in residential, office, hotels, hotel interior decoration. Material is not limited to paper, but also contains other materials. Because of the colorful, rich patterns, luxurious style, safety and environmental protection, construction convenience, affordable and other kinds of other interior materials can not match the characteristics, so in Europe and the United States, Japan and other developed countries and regions have been a considerable degree of popularity. Wallpaper is divided into many categories, such as film wallpaper, coated wallpaper, embossed wallpaper and so on. Usually with bleached chemical pulp production of base paper, and then by different processes of processing, such as coating, printing, embossing or surface coating, and finally by cutting, packaging after the factory. Has a certain strength, toughness, beautiful appearance and good water resistance.

Send your message to us

15mm Thickness Film Faced Plywood with Brown Color Film

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords