Atlantic Plywood 15mm Finger Jointed Film Faced Plywood for Building Usage

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m³

- Supply Capability:

- 1000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

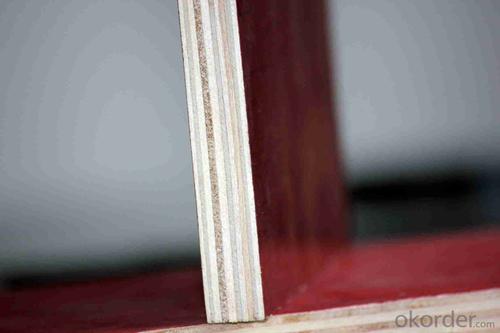

Specification:

Core: Poplar/birch/combi/hardwood core

Glue: WBP/Melamine/MR

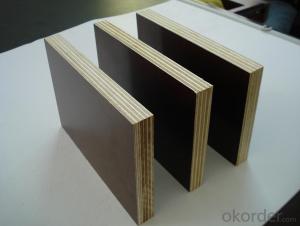

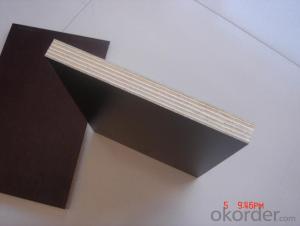

Film Color: Dark brown, black film. Other colors, like yellow, green, grey, can be specially ordered.

Thickness : 4 6.5 9 12 15 18 21 24 27 30 mm

Description:

Product | film faced plywood/marine plywood | |

Face and back | Brown film ,red film ,black film ,Dynea brown film | |

core | full poplar,full hardwood,combi core,birch core | |

thickness | 9-25mm | |

size | 1220*2440*9MM/12MM/15MM/18MM/21MM 1250*2500*9MM/12MM/15MM/18MM/21MM 610*2500*9MM/12MM/15MM/18MM/21MM 1200*1800*9MM/12MM/15MM/18MM/21MM | |

glue | MR,WBP-MELAMINE,WBP-PHENOLIC | |

tolerance | +-0.5mm | |

Moisture | below12% | |

grade | two times hot press one time hot press joint core(recycle grade) | |

Certificate | CE,ISO9001:2000,ISO14001:2000, FSC,CARB | |

packing | STANDARD EXPRT PACKING | |

Transportation | 1X20GP | 22.50m3 |

1X40'GP | 42.00m3 | |

1X40HC | 57.00m3 | |

Payment | T/T or L/C | |

Min order | 1*20GP | |

Delivery time | Within 15days after receiving TTdeposit or L/C at sight | |

Application | OUTDOOR USE ONLY, | |

Market | USA, Europe, Korea, North Africa, Middle East,Southern Asia | |

Supply ability | 5000 cbm per Month | |

port | Qingdao or Lianyungang port | |

Features:

1) Sizes: 1,220mm x 2,440mm, 1,250mm x 2,500mm,1,200 x 2,400mm

2) Thickness: 9mm, 12mm, 15mm, 18mm, 21mm

3) Core: poplar core, birch core, Hardwood core, combi core

4) Glue: MR glue, WBP glue

5) Film: black color, imported brown film, Chinese brown film

6) It has advantages of smoothness, non-distortion, light weight, high intension and easy application

FAQ:

1)Payment term:T/T deposit,balance against shipping documents,L/C.

2)Samples:free samples as request

3)Quality control:professional QC teams to make sure goods quality

- Q: Why plywood is cheaper than solid wood

- Without changing the physical properties of wood under the premise of drying, liposuction, paint and other processes can be called solid wood. Plywood (English: Plywood,

- Q: How to use building plywood?

- Four types of plywood for the tide resistant plywood, used in the indoor normal, general purpose plywood with beech, linden wood, ash, birch, elm, poplar and so on.

- Q: Plywood is generally used in applications where the strength and stability of the material are relatively high

- . It can do the floor of the container and other buildings and factories that need to be gravitational, and can be used as a scaffolding. Liquefied gas transport isolation box and so on.

- Q: What is the type of plywood editing?

- In order to make full use of forest resources to develop plywood production, make the best use of our country's newly developed national standards (draft approval) according to the use of adhesive pull

- Q: What is the use of plywood for construction?

- The number of veneer layers is odd, usually three to thirteen layers, common plywood, pallets, pallets

- Q: Distinguish between multilayer boards and plywood

- With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression.

- Q: Material for the plywood defects which

- Primary rot incipient decay The erosion of the fungus by the growth of the fungus causes a slight change in its chemical composition (usually before drying), showing slight changes in the hardness and discoloration, resulting in changes in the nature of the wood.

- Q: Class III resistant tide plywood class IV tonic resistant plywood

- and the dashboard and the inner panel are arranged symmetrically on both sides of the center layer or the core.

- Q: Today, most of the furniture is made of wood, pine, bakelite and popla

- . At that time, high-quality furniture, timber supply is sufficient, those who are not beautiful or poor durability of wood used only for non-exposed parts of furniture.

Send your message to us

Atlantic Plywood 15mm Finger Jointed Film Faced Plywood for Building Usage

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m³

- Supply Capability:

- 1000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords