Zinc Coating Galvanized Corrugated Steel Steel Zinc Roof Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Description of Corrugated Iron Sheet:

China coat galvanized corrugated iron sheet for roofing:

1.Raw Material: SGCC,SGCH, Full hard

2.Thickness: 0.14-1mm

Specifications of Corrugated Iron Sheet:

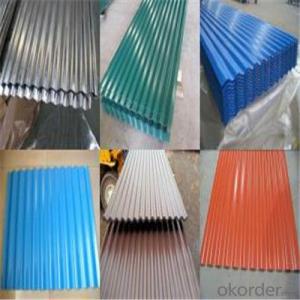

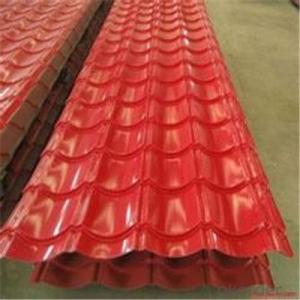

Surface Finish: normal coated, embossed patterns, printed patterns

Base Metal: hot-dip zinc coated

Paint Type: Polyester, silicon modified polyesters, high-durability polyester, and polyvinylidene fluoride

Types of Top Coatings: PE, Silicon modified polyesters, High-durability polyester, Polyvinylidene fluoride

Coating surface structure: Small spangle, Zero spangle

Features of Corrugated Iron Sheet:

*Long-term resistance to atmospheric corrosion

*Bright surface

*Paintability

*Durability

*Versatility

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q:How do steel sheets perform in corrosion resistance?

- Steel sheets perform well in corrosion resistance due to the presence of alloying elements like chromium and nickel, which form a protective oxide layer on the surface. This layer acts as a barrier, preventing the steel from coming into direct contact with corrosive agents, thus enhancing its durability and longevity.

- Q:How are steel sheets classified based on their surface finish?

- Steel sheets are classified based on their surface finish into different categories such as hot rolled, cold rolled, galvanized, and coated.

- Q:Are the steel sheets suitable for electrical enclosures?

- Yes, steel sheets are suitable for electrical enclosures. Steel is a highly durable and strong material that provides excellent protection for electrical components. It is resistant to impact, corrosion, and high temperatures, making it an ideal choice for enclosures that house sensitive electrical equipment. Additionally, steel sheets can be easily fabricated and customized to meet specific design requirements, ensuring a perfect fit for the electrical enclosure. Overall, steel sheets offer the necessary strength, durability, and protection needed to house electrical components effectively.

- Q:Can steel sheets be used for walkways or platforms?

- Certainly! Walkways or platforms can be constructed using steel sheets. Steel sheets are frequently employed in industrial and commercial settings owing to their durability, strength, and ability to withstand diverse environmental factors. They can be fabricated and installed to establish robust walkways or platforms capable of enduring heavy pedestrian traffic or the movement of equipment and machinery. Steel sheets can also be customized to fulfill specific design requirements, such as incorporating non-slip surfaces, raised edges for safety, or perforations for drainage. Furthermore, steel sheets necessitate relatively minimal upkeep and can be effortlessly cleaned and maintained, making them a perfect choice for walkways or platforms in various applications, including factories, warehouses, construction sites, and even outdoor areas.

- Q:Can steel sheets be recycled into other steel products?

- Yes, steel sheets can be recycled into other steel products. The recycling process involves melting down the steel sheets to remove impurities, and then reshaping and reforming the molten steel into new steel products. This helps conserve resources, reduce waste, and minimize the environmental impact of steel production.

- Q:Are steel sheets susceptible to rusting?

- Yes, steel sheets are susceptible to rusting if they are not adequately protected or exposed to moisture and oxygen.

- Q:Can steel sheets be used for signage or displays?

- Certainly, signage or displays can absolutely utilize steel sheets. Steel, being a versatile material, provides durability and strength, making it appropriate for applications indoors as well as outdoors. It is possible to cut, bend, or weld steel sheets into different sizes and shapes, enabling the creation of personalized signage or displays. The sleek surface of steel sheets serves as an outstanding medium for painting, printing, or applying vinyl graphics, making them perfect for showcasing logos, messages, or visual content. Furthermore, steel sheets can receive powder coating or galvanization to augment their resistance to corrosion, guaranteeing signage or displays that are both long-lasting and visually appealing.

- Q:Are steel sheets resistant to fire?

- Yes, steel sheets are highly resistant to fire due to their high melting point and the ability to conduct heat away quickly, which helps in preventing the spread of fire.

- Q:Are steel sheets suitable for exterior wall cladding?

- Yes, steel sheets are suitable for exterior wall cladding. They provide durability, weather resistance, and can be customized to achieve various aesthetic designs. Steel cladding is popular for its strength, low maintenance requirements, and ability to withstand harsh environmental conditions, making it an ideal choice for exterior applications.

- Q:What are the common thicknesses for corten steel sheets?

- The common thicknesses for corten steel sheets range from 1.5mm to 10mm.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Zinc Coating Galvanized Corrugated Steel Steel Zinc Roof Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords