WPC Crack Resistant Decking Hot Sell Traditional Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of WPC Crack Resistant Decking:

A safe, environmentally responsible alternative to traditional decks, conserving energy and resources. Not only does this save your time over the maintenance, but it will save you money as well.

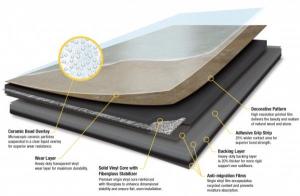

Composition of WPC Crack Resistant Decking:

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

Advantage of WPC Crack Resistant Decking:

· Maximum length: 6m

· UV resistance, durable

· Safe, environmentally responsible alternative to traditional decks, conserving energy and resources

· Low maintenance

· 100% recyclable

· Saves forest resources

· With look of natural wood but no timber problems

· Moisture/water-resistant

· No rotten, proven under salt water condition

· Barefoot friendly, anti-slip, no cracking and warping

· Requires no painting and glue

· Weather-resistant

· Termites, insects and moldy-proof

· Easy to install and clean

· Available in various colors

· Can be used in Temperature: -40 to +60°C

Installation of WPC Crack Resistant Decking:

Correct installation needs your high attention!

1 Always leave space (5-7mm) between 2 boards, or between board and wall.

2 Where there are 2 board ends meet, put 2 pcs of keels under each board end.

3 Keep the space of 2 keels at 25-750px.

4 Do not use glue to install.

5 Do not use our product where is always wet and sunless.

Other Information of WPC Crack Resistant Decking:

HS code: 3918909000

Time for production(1x20fcl): 15 days

Warranty: 10 years.

Certificate: CE, ISO

- Q:Plastic floor prices, plastic floor how much a square meter?

- Said plastic floor is plastic floor, also known as PVC floor. It is the main component of PVC, can be made into a homogeneous, floor bottom and surface pattern material is the same, can also be made into composite, it also can be made into printing.

- Q:Home decoration can use plastic floor it?

- PVC floor in the country is currently mainly used in engineering projects, a lot of manufacturers only note major projects, not enough emphasis on home improvement, which is the floor of the industry need to improve PVC. Manufacturers in the promotion of home improvement because of a variety of reasons encountered resistance, do not go to the next effort to promote, and naturally can not promote the popularity of PVC flooring in china.

- Q:Plastic foam flooring is not a large mosaic floor.

- When the children grow up, the floor needs to be replaced. What is the relationship between the damage to the floor, and then you can re paint it. Tiling can also be placed on the floor, you can let the children split up, spell the demolition, not much impact on the floor.

- Q:Home decoration house, because there is no time, all to the decoration company, now just installed, found the decoration company to use in the bedroom floor is only 0.7 cm thick, and skirting the bedroom are plastic, and the rest of the baseboard and tried hard to break. I would like to ask you how long this line can be used? Need to be removed and replaced with good quality? Will be removed when the...

- The thickness of the wooden floor should be stipulated in the contract, if you spent 1.2 cm price, he gave you installed 0,7 cm

- Q:Now decorated with qVC plastic floor can do

- Can be used, PVC plastic floor is widely used such as

- Q:The family is decorated with the plastic corrugated pipe buried in the floor tiles under the good?

- Every one in the family of 2-3 2.5mm root canal - wire is up to 3 4mm - 20, PVC tube enough protection layer plus 15mm, also tick the 40mm deep. This is the norm

- Q:What are the hazards of plastic floor

- Plastic floor leather, although difficult to burn, self extinguishing, but at high temperatures, will decompose harmful gases, excessive inhalation, suffocating

- Q:I would like to ask, can be affixed to the plastic floor tiles on the floor? The key is the room elevation uneven, generally have a difference of about 1 cm, the specific construction process?Do you know? Thank you, online, etc..

- The tiles can be spread on the floor, but the high ground surface roughness is not high at the end of 2 mm, 2 mm high as bottom difference with plastic floor foaming, high bottom difference obviously uneven, finally to rework, also have an impact on the life of the plastic floor! I suggest you do the ground put plastic floor, the following is our factory production and supply of products! The first price, the second material, third material odor (smell the heavier the price cheaper), the quality of the fourth accessories, the price of fifth accessories, the construction materials of the sixth, the material life of the seventh, after service

- Q:PVC plastic floor maintenance and maintenance, daily cleaning what is a good way?

- Wet mop. (with floor cleaning agent 1: 20 diluted with water, with a half wet mop mopping the floor.) if necessary, can also be used to clean the floor with wash & Shine low speed cleaning.

- Q:Water general plastic floor glue harmful to the human body

- The production process of domestic PVC sheet flooring is not mature, the compound PVC sheet flooring is a multilayer structure, domestic PVC manufacturers mostly use sheet flooring glue adhesive, in addition PVC production technology is not mature, especially in the use of additives, so the domestic PVC sheet flooring contain serious odor, the smell of formaldehyde gas

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

WPC Crack Resistant Decking Hot Sell Traditional Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords