Wood Finish Aluninum Composite Panel Modern

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 600 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Wood Finish Aluninum Composite Panel Description:

Wood Finish Aluninum Composite Panel is material proportioning and technical output, six-component mixed pouring technology,allowing on-line automatic operation which is the most advanced in the globe is adopted to take the lead in achieving six-component continuous foaming in China and finish proportioning process on line at a time; On the other hand, the formula can be adjusted in accordance with the environmental change to match with air-entrapping mixing unit to bring more well-distributed materials and finer foams for the purpose of producing high-strength, energy-saving and environment-friendly building boards.

Wood Finish Aluninum Composite Panel is a green building decoration material free of radioactivity, formaldehyde, heavy metals and other hazardous substances; in case of high temperature or open fire, no harmful gases and smoke are generated.

2.Main Features of the Wood Finish Aluninum Composite Panel:

Interior&exterior wall cladding panels

CE,SGS, 3.1220*2440MM

Unbreakable/ breakable LDPE core

PVDF for 15 years warranty

PE for 5-10 years warranty

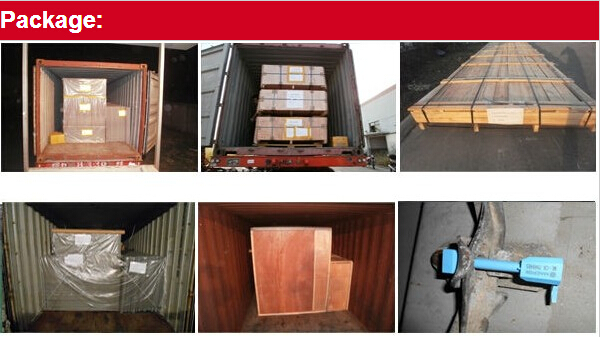

3. Wood Finish Aluninum Composite Panel Images

4. Wood Finish Aluninum Composite Panel Specification

Product Name | Aluminium Composite Panel |

Surface | PE or PVDF, Nano, Brushed, Mirror, Marble Look, Wooden Look, Glossy |

Core | LDPE, Fireproof |

Back Side | Primer or Mill Finish |

Aluminium Thickness | 0.06-0.50mm |

Panel thickness | 2mm, 3mm, 4mm, 5mm,6mm |

Width | 1220mm, 1250mm, 1500mm,1550mm,Less Than 1570mm |

Length | Any Length Less Than 6000mm |

Standard size | 1220 x 2440mm |

Weight | Around 5 kg/sqm based on 4mm thickness |

Aluminium Alloy | 1100 H18 or 3003 H24 |

5.FAQ

①What is the delivery time?

In general,Within 15 days

②How about Protective Film?

Alusunbond or in your brand name

③Do you provide Product Certifacate and Paint Mark?

Yes, provided.

- Q:Aluminum and aluminum plate What is the difference between ah

- Aluminum and aluminum-plastic plate is very different, aluminum-plastic plate for the composite board, both sides of the aluminum plate mixed with black PVC, both sides of the thickness of aluminum is generally about 0.5mm, the total thickness of about 4mm, aluminum is a single layer, no other

- Q:What is the fluorocarbon aluminum plate? What are the characteristics? What is the price?

- Outdoor aluminum-plastic plate is mainly used in fluorocarbon aluminum-plastic plate, Atari Fluorocarbon aluminum-plastic plate color effect is good, and has corrosion resistance, wear resistance, weather resistance is good, especially wood grain stone aluminum plate, appearance Not only with the wood material effect realistic, and the price is more affordable than wood stone. Fluorocarbon aluminum panels have super weatherability. As a result of the use of KYNAR-500-based PVDF fluorocarbon paint, weatherability has a unique advantage, both in the hot sun or cold snow are not detrimental to the beautiful appearance, up to 15 years fade. The coating is uniform and colorful.

- Q:Who knows Handan sell aluminum and aluminum-plastic plate where ah, to a large point of the place, said the address in detail, from the Wu An, first thank you.

- Can be considered to Guangdong side ah market big aluminum are better find professional production and processing of aluminum veneer aluminum mini

- Q:RT, I think these two are not the same thing? But, it seems not, we take this to do the printing, and now use the composite aluminum-plastic plate, but UV inkjet, will be out, others use aluminum Plastic composite panels, will not fall, so I think these two are not the same thing, please give guidance, these two kinds of relations, why, ...

- Aluminum-plastic composite panels and composite aluminum-plastic panels, are five words, only the order of different. Certainly the same type of product (material).

- Q:Which brand of aluminum veneer is good, where to find suppliers?

- Anhui Fu-day aluminum veneer manufacturers is very good, in Hefei, you can go and see

- Q:Roof by the wood core board base, do the slope; paste the ordinary aluminum-plastic plate, leaving 0.4cm seam, sealed with structural adhesive, after a winter, structural plastic cracks, causing multiple water leakage, some time ago to make up the seal Glue, the problem is not completely resolved. Will you prawn: If you do a waterproof above, how should construction treatment?

- The basic can not be made in the aluminum-plastic roof roof waterproof layer, even if not only difficult to do more difficult to build water also poor water.

- Q:What plastic glue can stick with the board?

- Omnipotent can be, some say that special glue, in fact, almost the same ingredients.

- Q:LED lights are normal, why the aluminum plate is also charged. And is 220V of electricity. Really scary.

- Under normal circumstances the aluminum-plastic plate is no electricity, but in the production will produce a certain amount of static electricity, static electricity is due to friction caused by, especially in the tearing protective film will produce a larger static, such as the body will be released near To the body, it is like playing the same, very little, see your situation is already decorated well, it may be because the line leakage, aluminum-plastic plate itself is a composite of aluminum metal composite board

- Q:Aluminum-plastic plate production line inverter has a specific role, can specifically say it?

- Automatic spraying equipment work process is through the conveyor chain will be sprayed into the high temperature oven, after a series of baking process so that the coating attached to the paint to be sprayed, and then sent by the transmission chain, the workers removed from the chain inspection, qualified Warehousing. Its electrical control system requirements can be adjusted according to different spray conveyor chain speed, in order to ensure adequate high temperature heating time, theoretically realized should be very simple, but because the conveyor chain is longer, the use of a single motor drag is very difficult, so the design Using two motors, which in turn a key issue is how to ensure that the two motor synchronization? Because if the synchronization will lead to the accumulation or breakage of the conveyor chain lead to the production can not be carried out, the three crystal inverter in the life of the speed of the death cycle control effectively solve the synchronization problem.

- Q:China made aluminum veneer building materials market where ah, take a lot of no, it touches on the agent auspicious aluminum-plastic plate

- China auspicious aluminum veneer, aluminum-plastic plate, aluminum honeycomb board, integrated ceiling aluminum ceiling, aluminum curtain wall, structural adhesive, sealant

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wood Finish Aluninum Composite Panel Modern

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 600 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords