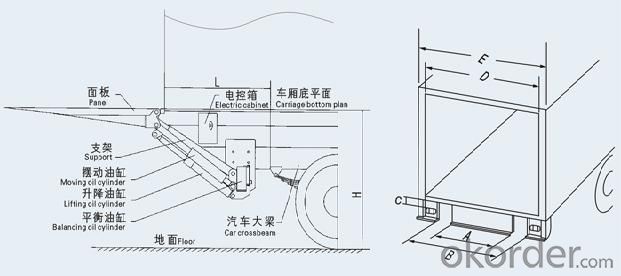

Truck tail lift (Truck tail liftboard)--DC-001

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General tailboard (including steel tailboard and aluminum alloy tailboard)

Aluminum Alloy Tailboard:

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Q:What kinds of tables are there? Which is better for the office?

- Lift table many brand, currently on the market the main lifting table is divided into: electric hoist, mechanical lifting table (barometric, mechanical lifting), electric lift table when the disadvantage is that there was no electricity can't use our company with polly lifting table, manual lifting regulation, any place to stay, very effort; And it can move back and forth

- Q:The characteristic of shear fork platform

- Shear fork lift platform is mainly used in the logistics industry, production lines, lifting, loading and unloading goods to floor between basement, can also be used to lift stage, lifting work station, etc. The product has a stable structure, low failure rate, reliable operation, safe and efficient and easy to maintain.

- Q:How to maintain the platform?

- My company has, our brand: niu power Throughout guangdong, there are 57 dealers across the country. Check it online, it's ok to buy it, but at least it will give you advice and contrast!

- Q:What are the elevating institutions

- The elevator is also called the elevating platform, which is a lifting device that lifts a person or cargo to a certain height. In the factory, the automatic warehouse logistics system such as vertical transportation, lifting platforms often also equipped with all kinds of plane conveyor equipment, as different height of conveyor line connection device.

- Q:How is the lifting handle of the universal knee-milling machine very tight

- Maybe it's too tight.I hope my answer will help you.

- Q:You need to make a small lift platform, on top of the robot, non-industry. What you want is to add a light pole with a nut and a bolt, and you can use an electric motor to turn the bolts and the nuts.

- It should be ok, but it's a little bit of a problem, which is that you have to be able to use an electric motor and you have to have a lot of power or you can use a decelerator,

- Q:How to use the elevator to be safer and more efficient

- Annual maintenance Check all hydraulic pipes and connectors. The pipe shall not be broken, the joints shall not be loose, and all the joints must be tightened. Remove and disassemble the descending valve, blow the plunger through compressed air, then load and resettle. Remove the hydraulic oil, remove the oil strainer and remove the oil strainer, clean it up and then put it back in the tank. Be familiar with 'ten notices' 1, pay attention to the agencies should regularly check and adjust the brake of the brake and the clearance between the brake wheel, flexible and reliable. The clean surface, there should be no dirt, in case of dirt must wash with gasoline or thinners. 2, pay attention to removing the hydraulic tank of fuel cap, remove the cap around earth, unscrew the cap, remove residual impurities in the joint area (not rinse in order to avoid water seeping into the tank), confirmed to open the cap. 3, pay attention to the elevator remove the hydraulic tank of fuel cap, filter cover, test hole, hydraulic tubing parts, cause the system oil when exposed to avoid dust, remove the parts to open completely clear before first.

- Q:When the hydraulic platform drops, it feels very shaken and unbalanced. Please answer?

- Connected to the solenoid valve is the control valve core, if it is to be repaired. To change oil, you need to lift it up to the top, and then use the safety support frame or stick to support it so that you can do what you want

- Q:What about the heat treatment of the lifting platform?

- Servo feed system stability is the most basic condition to work, especially when low speed feed does not produce "crawl", and can adapt to the change of the external loads and does not produce resonance. Stability is related to system inertia, rigidity, damping and gain. The life of the feed system, is mainly refers to keep the transmission accuracy of nc machine tools and positioning accuracy of the length of time, namely the transmission parts's ability to maintain its original manufacturing precision, therefore, should be a reasonable choice material, heat treatment and machining process to the transmission parts, and adopt suitable lubrication method and protective measures, to prolong life.

- Q:How to automatically lift up and lift

- The motor is controlled by a time relay, the motor is driven by a change of speed, and when it falls in place, it meets the power failure of the limit motor

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Truck tail lift (Truck tail liftboard)--DC-001

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products