Steel-frame Formwork for corner link

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

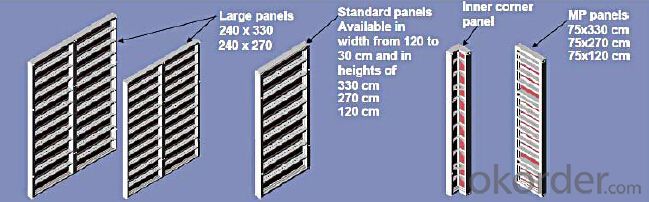

◆ The selection of panels.

◆ Kinds of panel connectors.

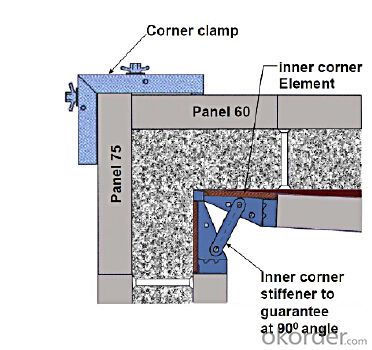

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q:What are the common quality control measures for steel formwork systems?

- Common quality control measures for steel formwork systems include: 1. Visual inspection: This involves checking the overall condition of the steel formwork system for any visible defects, such as dents, cracks, or deformations. Any damaged or compromised components should be repaired or replaced. 2. Measurement and dimensional control: Accurate measurements and dimensional control are crucial for ensuring the proper fit and alignment of steel formwork components. This can be achieved through the use of precision measuring tools and equipment. 3. Welding inspection: Steel formwork systems often rely on welded joints to connect the various components. Therefore, it is important to conduct thorough inspections of the welds to ensure they are free from defects, such as cracks or incomplete penetration. Non-destructive testing methods, such as visual inspection, ultrasonic testing, or magnetic particle testing, may be used to assess the quality of welds. 4. Load testing: Load testing is performed to verify the structural integrity and load-bearing capacity of the steel formwork system. This involves applying a predetermined load to the system and assessing its performance under stress. Load testing can help identify any weaknesses or defects that may compromise the safety and stability of the formwork. 5. Surface finish inspection: The surface finish of steel formwork systems should be smooth and free from any roughness or irregularities that may affect the quality of the concrete finish. Inspections should be carried out to ensure that the formwork surfaces are properly cleaned, treated, and coated, if required. 6. Documentation and traceability: Quality control measures should include proper documentation and traceability of the steel formwork system components. This includes maintaining records of inspections, repairs, replacements, and any other relevant information. Proper documentation ensures that any issues or concerns can be addressed promptly and accurately. These quality control measures are essential for ensuring the durability, safety, and performance of steel formwork systems in construction projects.

- Q:What types of structures can be built using steel formwork?

- Steel formwork is a versatile construction technique that allows for the construction of various types of structures. Some common types of structures that can be built using steel formwork include: 1. Buildings: Steel formwork is commonly used in the construction of residential, commercial, and industrial buildings. It provides a sturdy and durable framework for the concrete to be poured into, ensuring the structural integrity of the building. 2. Bridges: Steel formwork is widely used in the construction of bridges as it offers excellent strength and load-bearing capacity. It allows for the creation of complex bridge structures, including arches, beams, and deck slabs. 3. Tunnels: Steel formwork is also employed in the construction of tunnels, providing a temporary framework for the concrete lining. Whether it is for road, rail, or utility tunnels, steel formwork ensures the stability and durability of the tunnel structure. 4. Water-retaining structures: Steel formwork is suitable for building water-retaining structures such as tanks, dams, and reservoirs. It can withstand the pressure exerted by water and provides a watertight seal, ensuring the safe storage or containment of water. 5. Silos: Steel formwork is commonly used in the construction of silos for storing various bulk materials such as grain, cement, or chemicals. It offers the necessary strength and stability to withstand the weight and pressure of the stored materials. 6. Industrial structures: Steel formwork is widely used in the construction of industrial structures such as factories, warehouses, and power plants. It provides a rigid framework that can support heavy machinery and equipment, ensuring the safe operation of these facilities. 7. Retaining walls: Steel formwork is often employed in the construction of retaining walls, which are used to hold back soil or other materials. It provides a durable and stable structure that can withstand the lateral pressure exerted by the retained material. Overall, the versatility and strength of steel formwork make it suitable for a wide range of construction applications. It allows for the efficient and cost-effective construction of various types of structures, ensuring their durability and stability.

- Q:How does steel formwork prevent concrete segregation during pouring?

- To prevent concrete segregation during pouring, steel formwork offers a rigid and stable structure that securely holds the concrete in place. The steel panels are engineered to possess strength and durability, guaranteeing that they maintain their shape and do not bend or flex under the weight and pressure of the concrete. This effectively prevents the concrete from separating and segregating, an issue that arises when the formwork lacks sturdiness. Moreover, steel formwork is designed with tight connections and joints, effectively reducing the chances of any leakage. This is crucial because if water from the concrete mixture leaks out, it can lead to the separation and settling of aggregates, causing segregation. Therefore, the tight connections and joints contribute to maintaining the desired shape and dimensions of the concrete structure. Additionally, steel formwork is often treated or coated to prevent any chemical reactions between the concrete and the steel. This is of utmost importance as such reactions can result in concrete segregation and gradual weakening over time. Through the provision of a strong and stable framework, prevention of leakage, and avoidance of chemical reactions, steel formwork ensures that the concrete mixture remains homogeneous and properly integrated, effectively preventing segregation during pouring.

- Q:Are there any weight restrictions for transporting steel formwork?

- Yes, there are typically weight restrictions for transporting steel formwork. The specific weight restrictions can vary depending on the type of transportation method being used, such as trucks, cranes, or forklifts. It is important to adhere to these restrictions to ensure the safety of the transportation process and to prevent any damage to the formwork or the vehicle being used. Additionally, exceeding weight restrictions can also result in legal consequences, such as fines or penalties. Therefore, it is crucial to consult the relevant transportation guidelines and regulations to determine the specific weight restrictions for transporting steel formwork.

- Q:Can steel formwork be used for both single-story and multi-story structures?

- Yes, steel formwork can be used for both single-story and multi-story structures. Its strength, durability, and versatility make it suitable for various construction projects of different scales and heights. Steel formwork provides a robust framework for pouring concrete, ensuring stability and precision in the construction process, regardless of the number of stories.

- Q:Can steel formwork be used for architectural concrete finishes?

- Architectural concrete finishes can indeed utilize steel formwork. Steel formwork possesses several advantages that render it suitable for producing top-notch architectural finishes. Firstly, it offers exceptional dimensional accuracy and stability, guaranteeing that the concrete is poured and cured in the desired size and shape. This enables the achievement of precise and intricate architectural detailing. Moreover, steel formwork is highly durable and capable of withstanding the pressure and weight imposed by the concrete during the pouring and curing stages. Its durability ensures that the formwork remains intact, preventing any deformation or warping and resulting in a smooth and uniform concrete finish. Additionally, steel formwork facilitates easy demolding as it can be effortlessly dismantled without causing any harm to the concrete structure. This convenience is particularly advantageous for achieving architectural finishes that necessitate complex shapes or multiple components. Furthermore, steel formwork can be readily reused, making it a cost-effective choice for architectural projects. Its ability to withstand multiple uses reduces the necessity for frequent replacements, saving both time and money. However, it is crucial to acknowledge that the selection of formwork material depends on the specific requirements of the architectural concrete finish. While steel formwork proves suitable for most applications, there may be instances where alternative materials such as wood or plastic formwork are more appropriate. Seeking advice from a structural engineer or construction professional can aid in determining the most suitable formwork material for a particular architectural concrete finish.

- Q:How does steel formwork handle different concrete curing time requirements?

- Steel formwork is highly versatile and can easily accommodate different concrete curing time requirements. It offers excellent strength and durability, allowing for extended curing periods without compromising the structural integrity. Additionally, steel formwork provides a smooth and rigid surface that aids in achieving a consistent curing process. It can be easily assembled and disassembled, allowing for efficient adjustments to accommodate specific curing time requirements. Overall, steel formwork is a reliable choice that effectively handles different concrete curing time requirements.

- Q:Can steel formwork be used in high-rise construction?

- Yes, steel formwork can be used in high-rise construction. Steel formwork offers high strength and durability, making it suitable for withstanding the high pressures and loads experienced in tall buildings. It also provides excellent dimensional accuracy, allowing for precise construction and ensuring the structural integrity of the high-rise building. Furthermore, steel formwork can be easily assembled and disassembled, making it a time-efficient choice for large-scale projects.

- Q:Can steel formwork be used for elevated helipads?

- Yes, steel formwork can be used for elevated helipads. Steel formwork provides a strong and durable solution that can withstand the weight and impact of helicopters during takeoff and landing. Additionally, steel formwork can be customized to meet specific design requirements, allowing for the construction of elevated helipads with ease.

- Q:Are there any specific maintenance requirements for steel formwork systems?

- Yes, steel formwork systems require regular maintenance to ensure their longevity and efficiency. Some specific maintenance requirements can include cleaning and removing any debris after each use, inspecting for any signs of wear or damage, repairing or replacing any damaged components, lubricating the moving parts, and storing the formwork in a dry and protected environment. Regular maintenance helps to ensure that the steel formwork systems remain safe, functional, and durable for future construction projects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel-frame Formwork for corner link

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords