Stainless Steel Sheet 304 2mm hot rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description

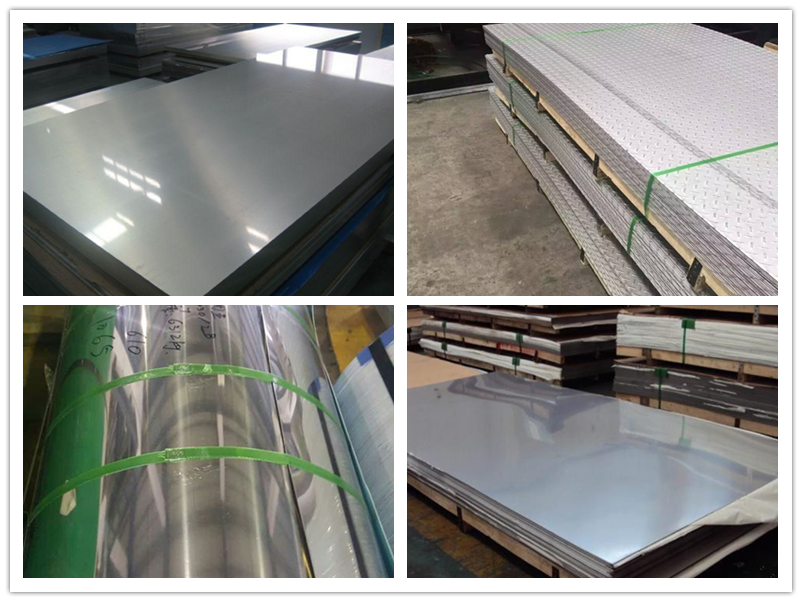

High Quality Cold Rolled Stainless Steel Plate,Cold Rolled Stainless Steel Plate,Stainless Steel Sheet,

Specifications

We offer superior quality stainless steel sheets, which have earned us wide admiration in the world market.

| Material | Size | Thickness | Specification | Manufacturer |

| Stainless Steel | 1000 mm x 2000 mm, 1220 mm x 2440 mm (4' x 8'), 1220 mm x 4880 mm, 1250 mm x 2500 mm, 1500 mm x 3000 To 6300 mm, 2000 mm x 2000 To 10000 mm, | 0.1 mm To 150 mm | A-240 | TISCO,LISCO. |

Grades:

304, 304L, 316, 316L, 317L, 321, 316 Ti, 309, 310, 904L, 410, 420, 430, 431, 202, etc.

Sheet Finishing:

2B, 2D, HR, CR, BA (No. 8), No. 4, Satin (Met with PVC Coated)

Sheet & Plate In Form Of: Coils, foils, shim sheet, perforated sheet, chequered plate, strip, flats, blank (circle), ring (flange), etc.

Value Added Service:

Cladding, heat treatment.

Annealed & pickling, polish & buffing.

Rolling, cutting, bending, forging, minor fabrication, etc.

Test Certificate:

Manufacturer Test Certificate

Laboratory Test Certificate from Govt. Approved Lab.

Under Third Party Inspection with Excise Gate Pass to avail Modvat benefit.

Specialize:

Shim sheet, perforated sheet (round, square & oblong hole) & as per your drawing

Packaging & Shipping

Application

- Q:Are stainless steel sheets resistant to saltwater?

- Yes, stainless steel sheets are resistant to saltwater. Stainless steel is known for its corrosion resistance, and it is particularly well-suited for environments with high levels of saltwater exposure. The chromium content in stainless steel forms a protective layer on the surface of the metal, preventing rust and corrosion. This makes stainless steel sheets an excellent choice for applications in marine environments, such as boat construction, offshore structures, and coastal infrastructure. Additionally, stainless steel's resistance to saltwater also makes it suitable for other applications like coastal architecture, kitchen equipment, and medical instruments.

- Q:Can stainless steel sheets be used for elevator mirrors?

- Certainly! Elevator mirrors can indeed be made using stainless steel sheets. Stainless steel, being both durable and versatile, is a favored material for elevator interiors due to its sleek and polished look. By polishing stainless steel sheets to a mirror-like finish, they can be effectively utilized as reflective surfaces for elevator mirrors. Furthermore, stainless steel's resistance to corrosion makes it well-suited for the humid and frequently challenging conditions typically encountered in elevators.

- Q:Are stainless steel sheets resistant to saltwater corrosion?

- Yes, stainless steel sheets are highly resistant to saltwater corrosion. Stainless steel is known for its exceptional corrosion resistance, making it an ideal material for applications exposed to saltwater environments. The chromium content in stainless steel forms a protective oxide layer on the surface, which acts as a barrier against corrosion. This oxide layer prevents the steel from coming into direct contact with saltwater, thereby reducing the risk of corrosion. Additionally, stainless steel grades such as 316 and 316L are specifically designed to offer better resistance to saltwater corrosion, making them even more suitable for marine applications. Overall, stainless steel sheets are a reliable choice for saltwater environments due to their excellent corrosion resistance properties.

- Q:What welding equipment do we need for welding stainless steel sheet and stainless steel square tube?

- 1 argon arc welding machine! If the person who has not been married, as little as possible, that thing has radiation, long time use of physiology is influential. You know what you do.2, regardless of the front and back can be, as long as it looks beautiful and practical.3, welding technology is good, it will not be ugly after welding.4, only the use of technology to make up for the lack of machinery, and then cattle B hardware, there is no good software is not good.5, welding rod, protective mask and so on.

- Q:Are stainless steel sheets good for pressure piping?

- Indeed, pressure piping benefits greatly from the utilization of stainless steel sheets. Possessing remarkable strength and durability, stainless steel is capable of enduring elevated pressure levels without succumbing to deformation or fracturing. Moreover, this material exhibits exceptional resistance to corrosion, rendering it highly suitable for the conveyance of pressurized fluids or gases in piping systems. Additionally, the ease with which stainless steel sheets can be cleaned and maintained further solidifies their reliability in diverse industries, including oil and gas, chemical, and food processing, where pressure piping applications are prevalent.

- Q:How do you calculate the cost of a stainless steel sheet?

- Calculating the cost of a stainless steel sheet involves taking into account several factors. To begin, it is necessary to determine the dimensions of the sheet, including its length, width, and thickness. These measurements will dictate the amount of material required, which is a crucial aspect in determining the cost. Another factor to consider is the grade of the stainless steel sheet. Different grades, such as 304, 316, or 430, possess distinct properties and are associated with varying costs. The specific grade necessary for a particular application will influence the sheet's price. The finish of the stainless steel sheet is also important to consider. Options like brushed, polished, or patterned finishes all entail different processes and materials, which in turn impacts the cost. Additionally, the quantity of stainless steel sheets needed can affect the overall cost. Bulk orders are often eligible for discounted prices, while smaller quantities may incur higher expenses. Conducting thorough research on different suppliers is crucial. Prices can fluctuate depending on factors such as the supplier's location, reputation, and prevailing market conditions. Comparing prices among various suppliers is essential to obtain the most favorable cost. It is worth noting that there may be additional costs involved, such as transportation fees, handling charges, or cutting fees. It is advisable to inquire about these potential expenses when requesting quotes from suppliers. By taking these factors into consideration and conducting comprehensive research, it is possible to accurately calculate the cost of a stainless steel sheet.

- Q:What are the different surface patterns available for stainless steel sheets?

- Stainless steel sheets offer a variety of surface patterns that each have their own unique appeal and practical benefits. One popular choice is the brushed finish, achieved by using a fine abrasive material to brush the surface of the sheet. This creates an elegant pattern of parallel lines and gives the sheet a sophisticated appearance. Moreover, the brushed finish helps to conceal scratches and fingerprints, making it a practical option for applications where appearance matters. Another commonly used surface pattern is the mirror finish, attained by polishing the sheet to create a highly reflective and glossy surface. This finish is often preferred in architectural and decorative settings where a sleek and luxurious look is desired. Additionally, the mirror finish is easy to clean and maintain. Embossed or textured patterns are also available for stainless steel sheets. These patterns are created by stamping or rolling the sheet with a specific design, resulting in raised or recessed areas on the surface. This not only adds visual interest but also enhances grip and slip resistance, making it suitable for flooring or industrial equipment. Furthermore, there are perforated stainless steel sheets with small holes or slots in a specific pattern. These sheets are commonly used in architecture for decorative screens or facades, as well as for filtration or ventilation purposes. The perforations can be customized in various shapes and sizes to meet specific requirements. In conclusion, the choice of surface pattern for stainless steel sheets depends on the desired appearance, functionality, and application. Whether it's the sleek brushed or mirror finish, the textured embossed patterns, or the versatile perforated sheets, there is a wide range of options available to suit different needs.

- Q:What is the thermal expansion coefficient of stainless steel sheets?

- The thermal expansion coefficient of stainless steel sheets typically ranges from 10.5 to 12.5 x 10^-6 per degree Celsius.

- Q:What is the width of the carbon steel coil and the width of the stainless steel coil, one is 1250, and the other is 1219?

- Domestic stainless steel rolling mill is generally 1219, but the design standard is 1300, so there will be flash board 1250, that is not the standard board, belonging to the flash, waste materials, many products manufacturers are also in 1219 as a reference size, product development, if the plate width will be wasted, a lot of scrap production the process, so the business order is generally around 1219 stainless steel coil.

- Q:Can stainless steel sheets be used in construction projects?

- Yes, stainless steel sheets can be used in construction projects. They are commonly used for various applications in construction due to their durability, corrosion resistance, and aesthetic appeal. Stainless steel sheets are often used for roofing, cladding, structural components, and decorative purposes in buildings and infrastructure projects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Sheet 304 2mm hot rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords