Stainless Steel Coils 300 Series Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Specifications for Stainless Steel Coils/Sheets:

Prodcut:Stainless Steel Coil

Thinckness: 0.20mm-8.0mm

Width:1000mm, 1219mm(4 feet), 1250mm, 1500mm, 1524mm(5 feet),

1800mm, 2000mm, 2200mm, 2500mm,and customizable

Ni:0.8~1.2% Cu:1.4~1.5% Cr:14

Standard: ASTM, JIS, GB, BS, DIN etc

Grade: 200series&300series&400series

Surface finish: 2B, BA, 8K, 6K, Mirror Finished, No1, No2, No4, Hair Line with PVC

Manufacture technology: cold rolled/hot rolled

Thickness Tolerance: +/-0.1mm

Width Tolerance: +/-10mm

200 Seriers: 201,202

300 Seriers: 301, 304, 304L, 316L, 309, 310S,321

400 Seriers: 410, 410S, 409L,430

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Application for Stainless Steel Coils/Sheets

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

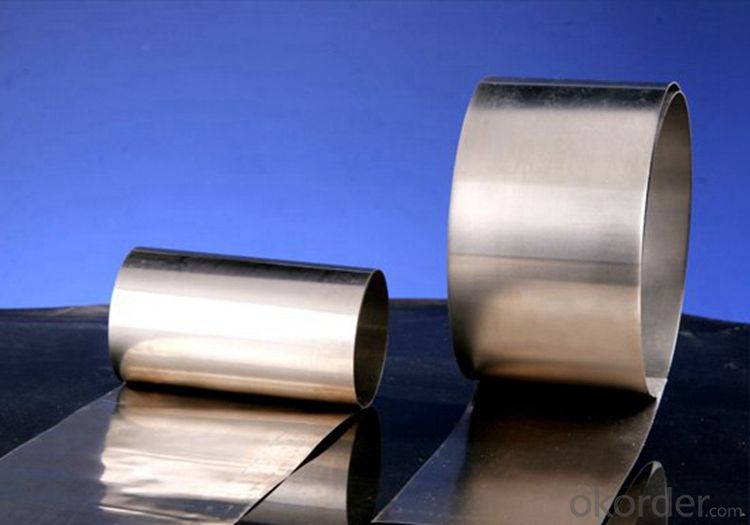

Detail picture for Stainless Steel Coils/Sheets

FAQ for Stainless Steel

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q:Are stainless steel sheets suitable for elevator doors?

- Yes, stainless steel sheets are suitable for elevator doors. Stainless steel is a popular choice for elevator doors due to its durability, corrosion resistance, and aesthetic appeal. Elevator doors are subject to constant use and exposure to various elements, making stainless steel an ideal material as it does not rust or corrode easily. Additionally, stainless steel sheets can be easily maintained and cleaned, ensuring a long-lasting and visually pleasing appearance. The versatility of stainless steel also allows for customization in terms of finishes, textures, and patterns, allowing elevator doors to be designed to match the desired aesthetic of the building or space. Overall, stainless steel sheets are a reliable and suitable choice for elevator doors.

- Q:What is the maximum temperature stainless steel sheets can withstand?

- The maximum temperature stainless steel sheets can withstand depends on the specific grade of stainless steel. Generally, most stainless steel grades can withstand temperatures up to around 1500°F (815°C) before experiencing significant oxidation or scaling. However, certain high-temperature grades of stainless steel, such as 310 or 321, can withstand temperatures up to 2100°F (1150°C) or even higher. It is important to consider the specific application and grade of stainless steel when determining the maximum temperature it can withstand to ensure optimal performance and durability.

- Q:Can stainless steel sheets be used for heat recovery systems?

- Yes, stainless steel sheets can be used for heat recovery systems. Stainless steel is known for its excellent heat resistance and durability, making it an ideal material choice for heat recovery applications. Its corrosion resistance and ability to withstand high temperatures make it suitable for capturing and transferring heat efficiently in various heat recovery systems.

- Q:Are stainless steel sheets suitable for architectural column covers or cladding?

- Architectural column covers or cladding can be effectively achieved using stainless steel sheets. This material is highly durable and resistant to corrosion, making it an ideal choice for outdoor applications. It can withstand various weather conditions without deteriorating or rusting. Furthermore, stainless steel provides a sleek and modern look, improving the overall appearance of the building. In addition, architects and designers can easily fabricate and install stainless steel sheets, allowing for a wide range of design options. Overall, stainless steel sheets are an outstanding choice for architectural column covers or cladding due to their durability, resistance to corrosion, aesthetic appeal, and ease of installation.

- Q:How do I prevent crevice corrosion on stainless steel sheets?

- To prevent crevice corrosion on stainless steel sheets, it is important to keep them clean and free from contaminants. Regularly cleaning the sheets with a mild detergent and water, followed by thorough drying, can help remove any corrosive agents. Additionally, ensuring proper ventilation and avoiding prolonged exposure to high humidity or stagnant conditions can minimize the risk of crevice corrosion. Applying a protective coating or using corrosion inhibitors specifically designed for stainless steel can provide an extra layer of protection against crevice corrosion.

- Q:Are stainless steel sheets suitable for aerospace applications?

- Yes, stainless steel sheets are commonly used in aerospace applications due to their excellent strength, corrosion resistance, and high-temperature capabilities. These sheets are suitable for various components such as aircraft bodies, engine parts, and structural elements, ensuring reliable performance and durability in demanding aerospace environments.

- Q:What type of welding rod is used for 304 stainless steel plate welding?

- A102 is Cr19Ni10 stainless steel electrode titanium calcium type coating, corrosion resistance of the deposited metal has good mechanical properties and resistance to intergranular, has excellent welding performance and anti porosity property, anti cracking, red medicine Pinai. A107 is a Cr19Ni10 stainless steel electrode with alkaline coating. The deposited metal has good mechanical properties and intergranular corrosion resistance. Therefore, they are aimed at 304 development of welding electrodes.

- Q:Comparison of three properties of aluminium plate, stainless steel plate and cold rolled plate?

- Cold-rolled steel plate is actually iron plate, with stainless steel plate characteristics, and the cost is low, but iron things, we know its shortcomings.

- Q:What are the different types of stainless steel sheet surface textures for decorative purposes?

- There are several types of stainless steel sheet surface textures that are commonly used for decorative purposes. These textures can enhance the overall aesthetic appeal of the stainless steel sheet and make it suitable for various applications. Some of the different types of stainless steel sheet surface textures include: 1. Brushed Finish: This texture is achieved by rubbing the stainless steel sheet surface with a fine abrasive material, resulting in a uniform satin-like appearance. Brushed finish is popular for its smooth and subtle texture, making it suitable for various decorative applications. 2. Mirror Finish: Also known as a highly reflective finish, the mirror finish is achieved by polishing the stainless steel sheet surface to a high gloss. This texture creates a mirror-like reflection and is often used in decorative applications where a sleek and modern appearance is desired. 3. Bead Blast Finish: This texture is created by blasting the stainless steel sheet surface with small glass beads, resulting in a matte and textured appearance. Bead blast finish is commonly used in decorative applications where a non-reflective and textured surface is desired. 4. Embossed Finish: This texture involves creating patterns or designs on the stainless steel sheet surface by stamping or pressing it with a patterned roller or plate. Embossed finishes can vary in pattern and depth, adding a visually appealing and tactile element to the stainless steel sheet. 5. Etched Finish: This texture is achieved by chemically etching the stainless steel sheet surface with an acid or other corrosive substances. Etched finishes can create various designs, patterns, or even images on the surface, making it ideal for decorative applications where intricate detailing is required. 6. Hairline Finish: This texture is created by mechanically polishing the stainless steel sheet surface with fine abrasive belts or brushes, resulting in a narrow and uniform textured pattern. Hairline finishes are commonly used in decorative applications where a subtle and elegant appearance is desired. These are just a few examples of the different types of stainless steel sheet surface textures available for decorative purposes. Each texture offers a unique visual and tactile quality, allowing for a wide range of design options when using stainless steel sheets for decorative applications.

- Q:Can stainless steel sheets be used for food processing?

- Yes, stainless steel sheets are commonly used in food processing due to their excellent corrosion resistance, durability, and ease of cleaning. They do not react with food, making them safe for use in various food processing applications such as food preparation surfaces, equipment, and storage containers.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Coils 300 Series Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords