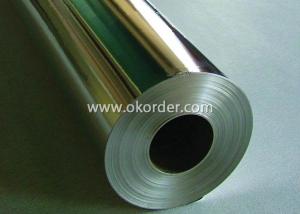

Silicone Coated Kraft Release Paper

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 MT m²

- Supply Capability:

- 400000 Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Silicon Release Paper technical data:

PARAMETERS | UNIT | VALUE |

Substance | gsm | 60-180 |

Laminated material | PE/PET/OPP | |

Base paper | wf paper/kraft paper | |

Colour | white/yellow/brown | |

Release force | g/25mm | ≥140 |

Moisture | % | 7 |

Tensile strength MD | N/cm | ≥30 |

Tensile strength CD | N/cm | ≥15 |

Heat resistance | °C | ≥120 |

Max width | mm | 1700 |

Silicon Release Paper Products feature:

1.) Professional quality control system

2.) Multi base paper woodfree paper, C2S art paper and brown kraft paper

3.) Multi colours in white, light yellow and brown

4.) Multi release force quality oem

5.) Heat resistance up to 120 degree

6.) Standard export packing and professional services

- Q:Waterproof electrode, waterproof welding

- 4, the first weld after the end of the weld there are a variety of defects. Such as: welding only in the wall surface, there is no penetration, welding weld when the inclusions and welding overflow quenching and melting of molten metal and so on. These defects in the original weld even if the re-welding, can not achieve the desired results. Therefore, in order to ensure the strength of the weld, should be added in the welding ribs, plate

- Q:What is the impact of TPO waterproofing membrane welding performance?

- Factors affecting the welding performance of TPO coil mainly in the following areas: 1. Material melting point and welding window;

- Q:Surfacing isolation layer is the application of what, how to achieve surfacing isolation layer weld.

- The surfacing isolation layer is mainly used to separate the main surfacing layer from the base metal, especially when the surfacing layer is welded directly to the base material. It is usually used with the third component, but with the surfacing layer and Base metal can be a good fusion of metal welding consumables, in the surfacing surface of the first welding a layer, and then on this basis and then need to re-welding the metal.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Silicone Coated Kraft Release Paper

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 MT m²

- Supply Capability:

- 400000 Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords