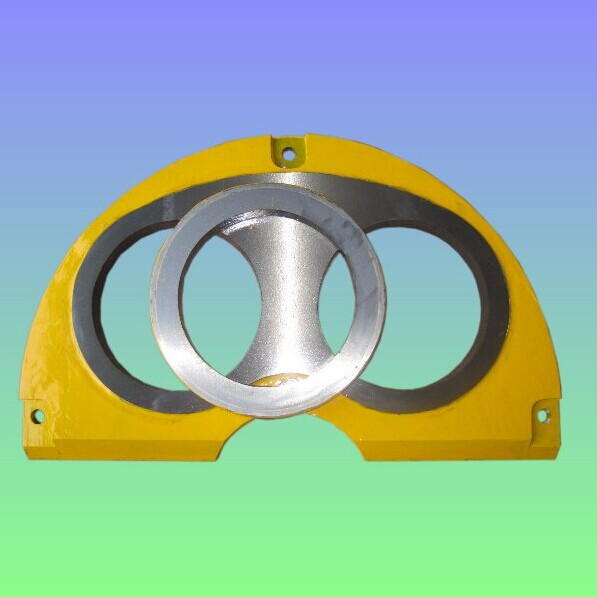

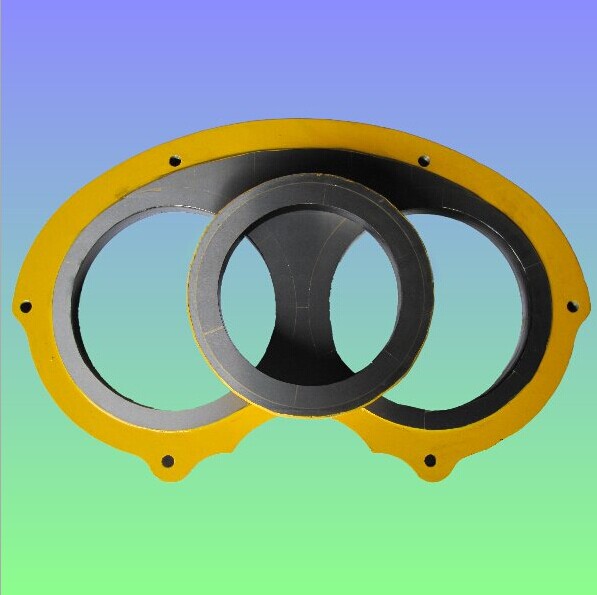

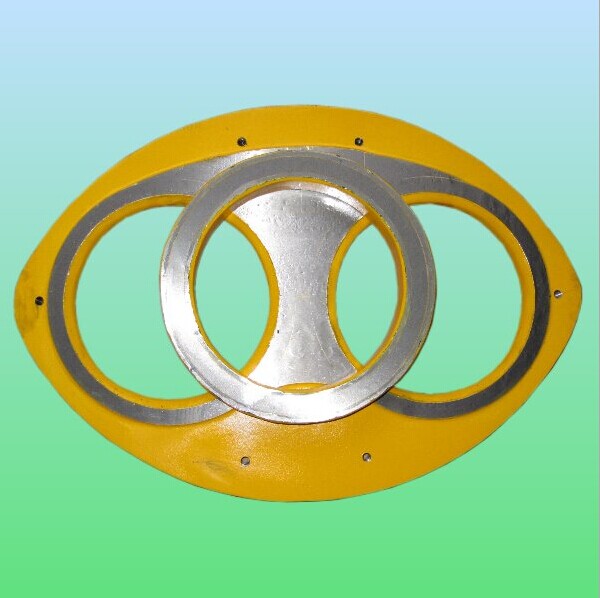

SANY Spectacle Plate and Wear Ring DN230

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name: SANY Spectacle Plate and Wear Ring DN230

1. Specification

1. Material: Plate body S35C steel, tungsten carbide E5 grade ,

2. Lifetime: 30,000~80,000cbm

3. HRA≥86

4. Germany Welding rod used for hardfacing

5. tensile strength ≥ 2500 N/mm2

6. Application: trailer and trunk mounted Sany concrete pump

Notes: total series of Concrete Pump Spectacle Wear Plate and Cutting Ring for different brand concrete pump (PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO,Niigata Etc) available from us.

2. Application

Our SANY Spectacle Plate and Wear Ring DN230 have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber pistons, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

3. Package

Every 60pcs SANY Spectacle Plate and Wear Ring DN230 put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: Why buy Materials & Equipment from us?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some SANY Spectacle Plate and Wear Ring DN230 according to customers request?

A4: Yes, we can produce SANY Spectacle Plate and Wear Ring DN230 according to the difference country situations and different concrete pump to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Images:

- Q:What are the types of concrete pumps?

- According to the structure and use of divided into drag type concrete pump, car pump and pump car

- Q:How long do concrete pump pipes typically last?

- Concrete pump pipes typically last between 25,000 to 40,000 cubic meters of concrete pumped. However, the lifespan of these pipes can vary based on several factors such as the quality of the pipes, the type of concrete being pumped, the pumping pressure, and the maintenance practices followed. Regular inspections, cleaning, and proper storage can help extend the lifespan of concrete pump pipes. Ultimately, it is essential to monitor the wear and tear of the pipes and replace them when necessary to ensure efficient and safe concrete pumping operations.

- Q:What are the different types of concrete pump hopper pins?

- There are several types of concrete pump hopper pins, including snap pins, lynch pins, and clevis pins. These pins are used to secure the hopper to the pump and ensure it stays in place during operation.

- Q:How do I properly maintain and replace wear plates in concrete pump spare parts?

- Proper maintenance and replacement of wear plates in concrete pump spare parts involves regular inspection, cleaning, and timely replacement. Firstly, inspect the wear plates regularly for any signs of wear, cracks, or damage. Clean them thoroughly to remove any debris or hardened concrete buildup. If the wear plates are worn out or damaged beyond repair, they should be replaced immediately to ensure optimal performance and prevent further damage to the pump. It is crucial to use high-quality replacement wear plates that are specifically designed for your concrete pump model. Following the manufacturer's guidelines and seeking professional assistance when needed will help ensure the proper maintenance and replacement of wear plates in concrete pump spare parts.

- Q:How long does it take to receive concrete pump spare parts after ordering?

- The time it takes to receive concrete pump spare parts after ordering can vary depending on several factors. It is important to note that the availability of the specific spare parts you need and the location of the supplier can significantly impact the delivery time. In general, if the spare parts are readily available and in stock, you can expect to receive them within a few days to a week. This assumes that the supplier has a streamlined order processing system and prompt shipping arrangements. However, if the spare parts are not in stock, it may take longer to receive them. In such cases, the supplier may need to order the parts from a manufacturer or source them from a distributor. This could add additional lead time to the delivery process, ranging from a few weeks to several months, depending on the availability and sourcing process. It is advisable to check with the supplier or manufacturer before placing the order to get an estimate of the delivery time. Factors like the supplier's location, transportation mode, and any potential customs or logistics delays should also be taken into consideration. To expedite the delivery process, some suppliers may offer expedited shipping options at an additional cost. This can be beneficial if you need the spare parts urgently. Overall, the time it takes to receive concrete pump spare parts after ordering can vary, but being proactive, communicating with the supplier, and planning ahead can help ensure a smoother and quicker delivery process.

- Q:What is the function of a concrete pump hopper grate pin?

- The purpose of a pin on a concrete pump hopper grate is to keep the grate securely in place and prevent it from moving or coming loose while concrete is being pumped. The pin acts as a locking mechanism, ensuring that the grate stays stable and does not pose any dangers or interrupt the pumping process. Furthermore, the pin allows for simple removal and replacement of the grate when needed, making it easier to maintain and clean the hopper. In conclusion, the concrete pump hopper grate pin is vital for preserving the reliability and effectiveness of the concrete pumping equipment.

- Q:What are the fittings of concrete pump?

- The commonly used electrical accessories (button switch, switch, trip circuit breaker, transformer terminals, etc.), hydraulic pipe

- Q:How can one extend the lifespan of concrete pump spare parts?

- There are several measures that can be taken to extend the lifespan of concrete pump spare parts: 1. Maintenance should be performed regularly. This includes cleaning, lubricating, and inspecting the parts for signs of wear or damage. By addressing any issues early on, further damage can be prevented and the lifespan of the parts can be prolonged. 2. Proper storage is important. When not in use, the spare parts should be stored in a clean and dry environment. Exposure to moisture, dust, and other contaminants can cause corrosion and deterioration of the parts. Storing them in a designated area with appropriate protection can help prevent these issues. 3. Investing in high-quality spare parts can greatly impact their lifespan. Choosing reputable brands and manufacturers that produce durable and reliable parts can ensure their longevity. Despite the initial higher cost, they will save money in the long run as they will require less frequent replacement. 4. Following the manufacturer's guidelines and instructions for the concrete pump spare parts is crucial. Overloading or operating the equipment improperly can put excessive strain on the parts, resulting in premature wear and tear. Using the parts within their recommended capacity and following proper operating procedures will help extend their lifespan. 5. Proper training and supervision of operators and maintenance personnel is essential. Educating them on best practices, proper handling, and maintenance techniques will prevent misuse or mishandling that can damage the parts. 6. Regular inspections should be conducted to identify potential issues early on. This includes checking for signs of wear, damage, or misalignment. By addressing these issues promptly, further damage can be prevented and the lifespan of the parts can be extended. By implementing these measures, the lifespan of concrete pump spare parts can be significantly extended, resulting in reduced downtime and improved efficiency in construction projects.

- Q:How can one determine the correct hardness and durometer rating for rubber components in concrete pump spare parts?

- Determining the correct hardness and durometer rating for rubber components in concrete pump spare parts requires considering several factors. Firstly, it is important to understand the specific application requirements of the rubber components. Factors such as the pressure, temperature, and frequency of use should be taken into account. Next, it is essential to consider the compatibility of the rubber material with concrete and other chemicals that may come into contact with the components. Chemical resistance is crucial to ensure the durability and longevity of the rubber parts. Additionally, analyzing the expected load and stress on the rubber components is crucial. Considerations such as the weight of the concrete, the force applied during pumping, and the potential impact or abrasion should be evaluated. Furthermore, environmental conditions should be considered. Factors like exposure to sunlight, extreme temperatures, or harsh weather conditions can affect the performance and lifespan of rubber components. Another aspect to consider is the specific type of rubber material used. Different rubber compounds have varying hardness and durometer ratings. Consulting with rubber manufacturers or suppliers who specialize in concrete pump spare parts can provide valuable insights and recommendations based on their expertise and experience. Ultimately, determining the correct hardness and durometer rating for rubber components in concrete pump spare parts requires careful evaluation of the application requirements, compatibility, load and stress factors, environmental conditions, and expert advice.

- Q:Are there any specific maintenance procedures for concrete pump spare parts?

- Yes, there are specific maintenance procedures for concrete pump spare parts. Regular maintenance is crucial to ensure the effective functioning and longevity of the equipment. Here are some key maintenance procedures for concrete pump spare parts: 1. Lubrication: Regularly lubricate all moving parts such as pistons, cylinders, and valves to minimize friction and wear. This helps to maintain smooth operation and prevent premature failure. 2. Cleaning: Clean the spare parts regularly to remove any debris, dirt, or concrete buildup. Accumulated material can hinder the performance and cause damage to the parts. Use appropriate cleaning agents and tools to ensure a thorough cleaning. 3. Inspection: Conduct routine inspections of all spare parts to identify any signs of wear, damage, or deterioration. Check for cracks, leaks, loose connections, or any abnormal functioning. Timely detection of issues allows for prompt repairs or replacements. 4. Replacement: Replace worn-out or damaged concrete pump spare parts as soon as necessary. Delaying replacements can lead to further damage and potentially expensive repairs. Follow the manufacturer's recommendations for the lifespan of specific parts and replace them accordingly. 5. Calibration: Ensure that all spare parts are correctly calibrated to maintain optimum performance. This includes adjusting pressure settings, flow rates, and other parameters according to the manufacturer's guidelines. Regular calibration helps to ensure accurate and efficient concrete pumping. 6. Storage: Properly store spare parts when not in use to prevent damage from environmental factors. Keep them in a clean and dry place, away from direct sunlight or extreme temperatures. Additionally, follow any specific storage instructions provided by the manufacturer. 7. Training: Train operators and maintenance personnel on the proper handling, maintenance, and repair of concrete pump spare parts. This will ensure that the procedures are followed correctly, minimizing the risk of damage and maximizing the lifespan of the equipment. By following these specific maintenance procedures, concrete pump spare parts can be kept in optimal condition, enhancing their performance, reliability, and longevity.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SANY Spectacle Plate and Wear Ring DN230

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords