Roll Forming Machinery -Sandwich panelPRL-6-SA3

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information:

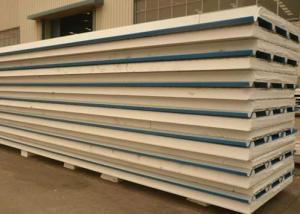

We can designthe line to make different kinds of panels in appearance, for wall panel androofing panel with various joint designs.

Sandwichpanel, as a new building material,shows excellent performance oninsulation.

It is takingthe place of brick to be a main material for building now.

High speedslitting and cut to length can cut steel with thickness from 1mmto 16mm, if noneed slitting thickness up to 30mm.

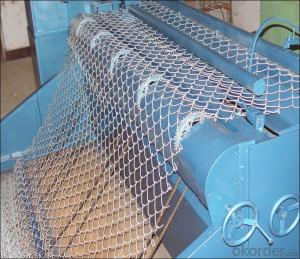

Processing flow is as following:

Carry coil→loadcoil→de-coiling(pressingguide +opener)→entry、roughlevel→cutting→transition→guide→slitting (waste winding) →loopingstorage→pre-separating, damping→recoiling→packing→discharging→guide→leveling→fix size (end platefeeding)→cutting→discharging

Technical Data:

1. TheManufacture Speed Of Sandwich Panel:8.6m/min( frequency conversion to adjustspeed)

2. TheThickness Of Sandwich Panel:30-200mm

3. TheThickness Of Steel : 0.4-0.8mm

4. TheLength Of The Production Line : about 120 meters

5. TheTotal Power Of The Production Line : 350 KW

6. TheLength Of The Double Belt Conveyer : 24m

- Q:How can the wire laying in the foam sandwich panel workshop meet the fire protection requirements?

- Outside the wire is a pipe, that is, through the pipe laying, if the pipe is galvanized steel pipe, and buried in the wall, floor, floor and so on inside can not see, it is called galvanized steel pipe concealed.

- Q:How to install the pre embedded pipe in the clean room sandwich panel?

- Clean room decoration requirements are very special, do not allow the use of decorative lines and other special protrusions, Yin, Yang Kok should be made of arc, wall and ceiling should be smooth, smooth, no seams or seams tight.

- Q:What is the color steel sandwich board?

- The intermediate sandwich panel is two color steel with polyurethane foam with a layer of insulating material.

- Q:How is the sandwich plate synthesized?

- The forming of the outer steel plate fully takes into account the structural and strength requirements, and takes into account both the beauty and the appearance of the inner layer to form a flat plate to meet various requirements.

- Q:Rock wool, color steel sandwich plate production line where good?

- Jizhong Machinery Manufacturing Co., Ltd. has won the title of state-level high-tech enterprises, and has been recognized by the Ministry of Commerce as a designated equipment export manufacturer.

- Q:Polyurethane sandwich panel production line?

- Products are mainly used for exterior wall insulation and central air conditioning, air supply pipe. The working principle of polyurethane perfusion machine by measuring liquid pump in a certain proportion into the mixing head after mixing evenly pouring in sandwich bottom material, and the upper surface of a layer in the layer of transport to the press, press under the chain plates foam curing; sandwich plate after curing in the production line both sides trimmed, automatic track cutting machine cut to length of the products.

- Q:How to thread the EPS (color steel) sandwich panel?

- EPS plate can not use the dark cable way, must use PVC flame retardant pipe line, need to use the hole opening device, open out also good-looking.

- Q:Classification of sandwich panels

- Polystyrene sandwich board, or EPS sandwich panel (the most widely used product on the market);Extruded polystyrene sandwich panels, i.e., XPS sandwich panels;

- Q:What's the difference between sandwich board and composite board?

- Building insulation board industry, insulation composite board refers to sandwich board, composite board is popular name.

- Q:What are the causes of uneven surface of polyurethane sandwich panel produced by continuous production line?

- Uneven heating of sheet material leads to uneven solidification of Pu material.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Roll Forming Machinery -Sandwich panelPRL-6-SA3

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products