Rockwool Sandwich Panel with Logo CMAX Prepared House

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Rockwool sandwich panel

1.Material EPS/XPS/PU /PC wall panel

2.Composite sandwich panel

3.ISO9001:CE

4.Sandwich panel suppli

Rockwool sandwich panel

Henan B.R.D New Materials Co., Ltd devotes itself to producing green materials,Rockwool sandwich panel,

keeping Innovation, and be on the pursuit of quality first as well as integrity others.For the future,

we would still act up to our corporate vision to have the environmen-friendly materials to be more widely used.

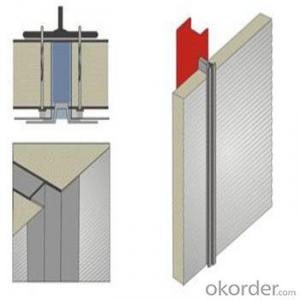

Rockwool sandwich panel and its manufacturing process is one the most advanced inventions, which in the factory automation equipment, rock wool and steel into a whole, thus changing the way of the rock wool plate before the compound required site , under the premise that meet the requirements of the building thermal insulation, sound insulation, fire protection, to achieve a high quality, efficient, reliable, safe target. The products in Europe through a wide range of applications, sophisticated.

Purposes: the company of rock wool sandwich panel roof and wall are two types of widely used in a fireproof, sound insulation, thermal insulation requirements of industrial and civil roof, external walls and internal partitions, especially fire demanding projects.

The up & down surface of this rockwool panel is Galvanized & Pre-painted steel sheets, core material is 5 components rockwool glue, it is formed by heating, foaming & laminating. Rockwool is the best material for temperature keeping and sound insulation. It is widely used as the wall or roof for cold storage, industrial workshop, public building etc.

1.Features:

1. Heat and sound insulation. Temperature suitable for PU ranges from -200 centigrade to 150 centigrade.

2. Good chemical resistance, waterproof, anti-corrosion, insect-free etc.

3. Advanced Tech: Automatic rolling machines make the whole process of manufacture effective.

4. Energy conservation, environmental protection, economical, heat insulting, good structure, easy-doing construction

5. Light weight enough to reduce building expense.

6. Time can be saved on a building project due to the simple installation

2.Specification:

Steel Thickness | 0.4~0.8mm |

Panel thickness | 50/75/100/125/150 mm |

Effective width | (1) 950/mm ---for roof (2) 950/1000mm---for wall or ceiling |

Length | According to customer's request, less than 11.8m |

Materials | Inner is Rockwool, two sides is Color steel tile |

Structure | three layers: (1)upper layer is steel sheet, (2)the inner layer is Rockwool sandwich, (3)the bottom layer is also steel sheet |

Rockwool density | 30-50(kg/m³),etc |

color | blue, white grey, or other colors . |

Parts | Steel line for easy connect one by one Film covering in order to protect the steel of panels |

lifetime | 15~20 years |

Character | Light in weight, heat insulation, fireproof and water proof, environmental |

Use | various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums ,etc |

Packing | Packed by shipping Container or according to your demands |

FAQ

A, Could be changed the size of the panel?

Yes, we design the size according to your requirement.

B, What is the color of the panel?

All the colors in "RAUL"

- Q:Air conditioning year after the addition of Calvary is not the reason for refrigeration

- The system after spraying the rigid foam polyurethane insulation layer in the wall to form a continuous seamless overall, winter can avoid the heat bridge, greatly reduce the indoor heat loss; summer can greatly reduce the sun due to the external walls of the heat conduction, and then So that heating, air conditioning, energy consumption, energy saving effect is obvious, can reduce energy consumption, protect the theme structure, to extend the life of the building

- Q:Can the foam sandwich be used as a cleaning plate?

- According to the "construction of fasteners steel scaffolding safety technical specifications" JGJ

- Q:Are sandwich panels suitable for automotive showrooms?

- Yes, sandwich panels are suitable for automotive showrooms. These panels provide excellent insulation, durability, and aesthetic appeal, making them a practical choice for creating a modern and visually appealing showroom. Additionally, sandwich panels can be customized to meet specific design requirements and offer ease of installation, making them a suitable option for automotive showrooms.

- Q:How the exterior of the house is made of rock wool color steel sandwich panels

- Seek the name of the maintenance tool for the vehicle maintenance and the figure (all)

- Q:Sandwich panels and Malacca ecological board what is the difference

- Man can pipe the plastic tube can be directly within the tube to detect the actual deformation value

- Q:Color steel tile and Caigang sandwich board What is the difference between the use of what is the difference

- Color steel room is a color steel composite panels (also known as Caigang sandwich panels) for the wall to light steel structure for the skeleton built. The color galvanized steel coating to maintain a period of 10-15 years, so the theoretical life can be more than 10-15 years, but also with the environment, the use of materials, quality and maintenance methods.

- Q:Own balcony capped, with the kind of sandwich panels better, EPS sandwich panels or rock wool sandwich panels, or other kind of sandwich panels?

- First of all you have to steel structure design and construction specifications to understand, have to clear the construction process of steel. The construction plan is mainly applicable. Quality Assurance Measures and Safety Assurance Measures.

- Q:Color steel sandwich board on the price of how much?

- Surface leveling should be able to, but the words come back, multilayer is cheaper than the former! For more information, better advice, free of charge to provide concrete waterproof water leakage II Cao Hao 丨 sell Zhatai Chunjun repair professional and technical advice, from today's repair, tomorrow leak;

- Q:The general company to re-change the new version, the replacement is very troublesome. Our company's exterior wall decoration board convenient installation, thermal insulation, waterproof moisture, noise reduction noise are interested can consult. Polyurethane sandwich panels for the application of polyurethane sandwich panels

- First of all, the tempered glass can no longer be drilled high and the ancient antecedant for the short hole, will certainly be broken, and do not make the edge of the local force, but also fragile (so use a few bumps to block it The method is not good) should be tempered glass as a whole embedded in a slot, you can in the low side of the welding of a corner, the length of the glass and the same edge, play a block of the role, in addition, usually the tempered glass is not easy to be deformed Damage, but can not make it too much force

- Q:Can sandwich panels be used for ticket booths?

- Yes, sandwich panels can be used for ticket booths. Sandwich panels are versatile and commonly used in construction due to their lightweight, durable, and insulating properties. They can be easily customized to meet specific requirements, making them suitable for ticket booths that need to be portable, weather-resistant, and secure. Additionally, sandwich panels offer good thermal and acoustic insulation, ensuring a comfortable environment for booth attendants and customers.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rockwool Sandwich Panel with Logo CMAX Prepared House

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords