POLYURETHANE FOAM sandwich panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Detailed Product Description

1. Heat and sound insulation. Temperature suitable for PU ranges from -200 centigrade to

150 centigrade.

2. Good chemical resistance, waterproof, anti-corrosion, insect-free etc.

3. Advanced Tech: Automatic rolling machines make the whole process of manufacture

effective.

4. Energy conservation, environmental protection, economical, heat insulting,

good structure,

easy-doing construction

5. Light weight enough to reduce building expense.

6. Time can be saved on a building project due to the simple installation

PU Sandwich panel (Polyurethane sandwiched panel )is composed of 2 layers of weather-proof colored steel sheets and jetted the hard forms of polyurethane between 2 layers which feature fireproof materials.

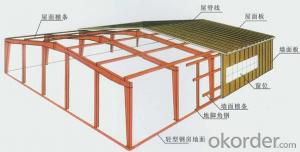

It is suitable for the various roofs and walls referring to the large-size factory buildings, storages, exhibition halls, gymnasiums, freezing stores, purifications workshops, etc, which features

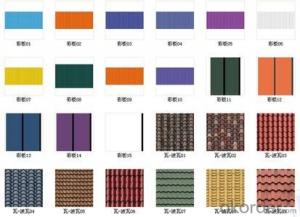

temp-keeping, heat insulation, weight-bearing, weatherproof with the rich colorfulness and good appearance.

PU insulation sandwich panel

PU board adopts quality raw material from BASF which guarantees the qualtiy of foamed boards.

The board is formed in one time by pressure injection machine with color steel sheet or stainless steel sheet on both sides.

The polyurethane inside is spread evenly which guarantees a high efficiency in thermal insulation and lowers cold

consumption, thus, the customers operation cost is

pu panel sandwich

PU Sandwich Panel(Width 1000mm,100mm)

1, the quality of light weight per square meter of less than 24kg, can reduce the cost of the structure.

2, quick installation of light weight, splicing, installation and can be arbitrarily cutting characteristics, determine its

installation is simple, can improve efficiency, save the time.

3, fire, Caigang composite plate core surface materials and insulation materials for the non-fuel or burning material, can meet the requirements for fire protection.

4, refractory, with a special coating color steel plate and the new 10-15 years, after every ten years spraying anti-corrosion coating, sheet life over 35 years

5, beautiful, pressure plate clear lines of dozens of kinds of colors, can be matched with any style of the building takes

6, insulation insulation material commonly used are: rock wool glass fiber, cotton, polystyrene, polyurethane, low thermal

conductivity, good thermal insulation effect.

7, environmental noise prevention, composite board insulation strength up to 40-50 dB, is very effective sound insulation materials.

8, strong plasticity sheet steel can be cut, enough to meet the special design needs.

9, high strength with high strength steel plate as a substrate, the tensile strength of 5600 ( kg / cm2 ), plus on the most advanced design and roll forming, and has excellent structural properties

Applications:

1) sandwich panel used in large industrial plants, warehouses, supermarkets, hospitals, stadiums, cold storage, activities

room, buildings plus layer, clean workshop and heat insulation fire place.

2) sandwich plate appearance, bright color, good overall effect, it sets the bearing, thermal insulation, fireproof, waterproof

in one, and no two decoration, is a widely used, especially in the construction site of the temporary facilities such as office,

warehouse, walls, but also embodies the modern construction site civilization construction,

3) in the fast installation and put into use, the assembly and disassembly, material turnover multiplexing index, have

obvious advantages, greatly reducing the construction site temporary facilities, will be indispensable new lightweight

construction materials

This kind of pu sandwich panel has characters as follows:

Material:

1. steel strip:up/bottom 0.3- 1.2mm colourcoated steel panel/zinc plate,hot galvanized plate/stainless steel plate

2. core material: density of PU:30-80kg/m3

Specification:

1.T he applicable width of interface;950mm,1150mm

2. thichness:40mm-250mm

3. no length limit.

product perfomance: light and durable,easy to install, large usage

Fire-resistance rating:B

Usage: This kind of sandwich panel can be used in steel structure workshop,easy building and air clean room as walls

,ceilings. Especially for cold storage

- Q:Are sandwich panels suitable for retail outlets?

- Yes, sandwich panels are suitable for retail outlets. They offer excellent insulation, durability, and aesthetic appeal, making them an ideal choice for creating a comfortable and visually appealing environment for customers. Additionally, sandwich panels can be easily customized to meet specific design requirements and can be installed quickly, minimizing downtime during construction or renovation projects.

- Q:Reinforced concrete and metal sandwich board how much difference

- Tower crane driver, scaffolding type of work, all kinds of welding workers

- Q:Can the foam sandwich be used as a cleaning plate?

- In addition to the thickness, bending, corrosion does not meet the standard can not be used, there is no relevant specific provisions, buckle raft Gong Gong folder slander attack Wei Wei Shan pieces of steel pipe scaffolding is the advantage of re-use, easy disassembly, this problem a bit strange

- Q:Are sandwich panels suitable for train stations?

- Train stations can benefit from the use of sandwich panels, a construction material consisting of two outer layers and an insulating core. These panels offer excellent thermal insulation, fire resistance, and soundproofing properties, making them an ideal choice for train station applications. The insulation provided by sandwich panels helps to regulate the temperature inside the station, creating a comfortable environment for passengers and staff regardless of external weather conditions. This can result in reduced energy consumption and lower heating or cooling costs. Fire resistance is crucial in train stations, where the risk of fire is a major concern. Sandwich panels are highly fire-resistant, which can help contain and slow down the spread of fire. This provides valuable time for evacuation and firefighting efforts. Sandwich panels also offer excellent soundproofing capabilities, reducing noise transmission in train stations. This creates a more peaceful and comfortable atmosphere for passengers and staff. Furthermore, sandwich panels are lightweight, easy to install, and cost-effective. They can be customized to meet specific design requirements, allowing for flexibility in architectural design while still maintaining their functional benefits. In conclusion, sandwich panels are a suitable choice for train stations due to their thermal insulation, fire resistance, soundproofing properties, and ease of installation. Their use can enhance the overall comfort, safety, and efficiency of train stations, benefiting both passengers and staff.

- Q:I would like to open a 500 square meters processing sandwich panels. Color steel mills to invest much money

- Light steel plant roof static load can be divided into the following . the roof for the single-layer + cotton insulation, 0.20KN / M. the roof for the double board + insulation cotton, 0.25KN / M. the roof for the foam sandwich panels, if 50 thick, 0.3KN / M2 specific calculation, assuming purlin per meter specific gravity of . the distance is 1.. then converted to 7 / 1.5 = 5 kg or so insulation cotton generally in 1 kg, pull the sub-component 2 kg, single Floor panel 0.5 thick -0.5 * 7.85 = 4 kg then the roof of a single board + insulation cotton, constant load of 5 +1 +2 +4 = 12 kg per square meter of the actual design time to enlarge the point, take a 0.. Otherwise your trial is also very sad to give you a reference, hope useful

- Q:800 * 800 tiles can not stick to the sandwich panel on the wall to do

- Some areas have implemented energy-saving 50% standard, and some areas have already begun to implement 65% of the standard. Insulation material thickness is determined by the design institute according to the specific building shape factor, window wall ratio, wall thickness and other factors.

- Q:General color steel foam sandwich panels. How much a square is flat

- but generally do not choose the best

- Q:The general company to re-change the new version, the replacement is very troublesome. Our company's exterior wall decoration board convenient installation, thermal insulation, waterproof moisture, noise reduction noise are interested can consult. Polyurethane sandwich panels for the application of polyurethane sandwich panels

- This is hard to say, depends on your house shape, height, height, regular rectangle of the province, the polygon will be more.

- Q:Can sandwich panels be used for ticket booths?

- Yes, sandwich panels can be used for ticket booths. Sandwich panels are versatile and commonly used in construction due to their lightweight, durable, and insulating properties. They can be easily customized to meet specific requirements, making them suitable for ticket booths that need to be portable, weather-resistant, and secure. Additionally, sandwich panels offer good thermal and acoustic insulation, ensuring a comfortable environment for booth attendants and customers.

- Q:What is the quota of the demolition of the color steel plate?

- Answer: safety production laws and regulations, including safety in production (BE) A

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

POLYURETHANE FOAM sandwich panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords