PVC Wood Flooring, Wood PVC Flooring Plank, Vinyl Linoleum Floor

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Specifications

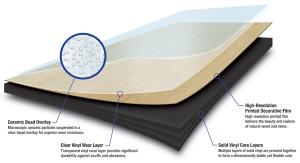

W/L: 0.5mm

Surface: Crystal Texture

Vinyl Plank

UV matt

Size: 1227*157*3.0mm

Why Choose Us

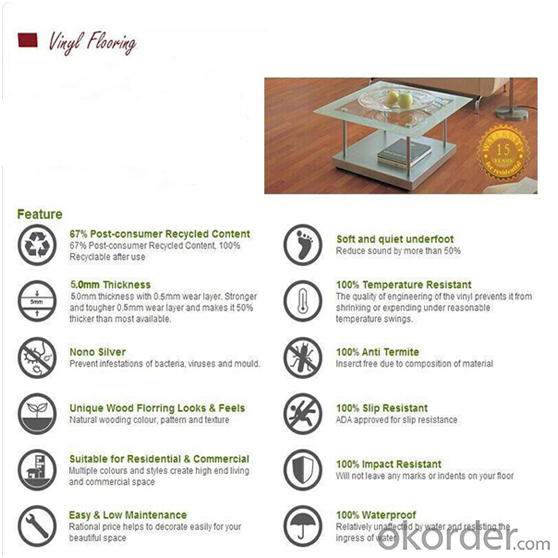

1. 15-Year professional experience in CNBM Flooring.

2. The Fastest Delivery Speed

3. Excellent After-sales Service

Technical Data

Safety Criteria | Standard | Value |

Flammability | EN 13501-1 | Bf1 |

Slip resistance | EN13893 | DS |

Formldehyde Emission | EN717-1 | None |

Color Fastness | ISO 105-BO2 | ≥ 6 |

Castor Wheel Test | EN425 | Pass |

FAQ

1.Q:How do you guarantee the quality of your PVC vinyl flooring?

A:Each step is strictly controlled by the QC team to make sure all our products turn out great

2.Q:Do you offer other products besides PVC vinyl flooring?

A:Yes. Besides PVC vinyl flooring we also provide matching profiles such as T-molding, skirting, stair-nose etc.

3.Q:Can you offer packing designs as per customers’ requests?

A:Of course. Usually we have several fixed packing designs for floor traders to select.

4.Q:Are samples available?

A:Of course. As flooring suppliers we are willing to supply samples to our customers for further checking. just tell us the specifications of laminate flooring that you need.

Instrctions:

1.Remove the floor trim fromt he perimeter of the floor with your hammer and prybar. Don't break it. Set it aside.

2. Lay the first row of this vinyl tiles alongside your starting wall, locking them together at the ends. Put shims between the tiles and the wall, to create a space that will allow for floor expansion. Lay all the full tiles that will fit.

3. Measure the space at the end of the first row of tiles. Use your utility knife to cut a tile to size, running the knife alongside a straight-edge to score it, and then snapping the tile. Lay it with the cut side facing the wall.

4. Lay the next courses of tiles alongside the first building out in courses. Start each course at the opposite end of the room as the previous course, so the ends of the tiles don't line up between courses. Lock the tiles together by their long edges,pushing them in at a downward angle, locking then, then dropping then into space. Cut the ends as necessary.

- Q:What is the difference between hard and soft plastic floor construction

- If I tell you, will you kill me? Well, tell you, in fact, the difference is not big, not fire

- Q:What is the difference between PVC plastic floor and composite floor?

- PVC floors and wood floors: wood floors can be broadly divided into three categories: solid wood flooring, solid wood flooring and laminate flooring. The wood floor is natural materials, synthetic materials have irreplaceable advantages, non-toxic and tasteless, comfortable, warm in winter and cool in summer.

- Q:What are the differences between plastic floor and floor tiles

- Plastic floor is the main material for PVC resin, and the composite floor is composed of the wear-resistant layer five layer structure, through a special process, with heat resistance, moisture resistance and deformation, anti-aging, antibacterial, mute, abrasion resistance, fire retardant etc.. Plastic floor, also known as PVC floor, mainly in PVC materials (polyvinyl chloride) as raw material for the production of ground decorative materials. Some people call it plastic floor, floor board, floor glue, floor leather, a variety of names, different regions are also different names

- Q:Is it the heat of the plastic sheeting does not affect it? Do you really have a moisture-proof effect?

- Can prevent the wood floor directly contact with the ground moisture

- Q:Plastic floor to allow welding joints

- Seam stitching: elastic floor in the laying, the two floor edge overlap 20mm or so, and then cut off with a knife, forming dense joints. The joints are not connected together.

- Q:My landlord in the balcony painted a thick paint, more than two months later, the smell is still very large, in order to health, and the landlord to negotiate, they agreed to remove the paint layer, but to keep the corner part. Now two days to remove the paint layer, but the smell is bigger. Now I want to purchase the floor, then at the boundary with plastic tape sticking. Do not know whether it can isolate formaldehyde, etc....

- Can not be separated, if you do so will only slow down the rate of evaporation of formaldehyde. Formaldehyde according to the presence of the environment and other external conditions of the most volatile up to 20 years, the fastest also get 3-5 years.But there is a good way to remove formaldehyde.You can buy dried flowers made photocatalyst. Or ask them to give you a home brush paint, but the price is very high.

- Q:What a pig with plastic floor to sell, how much money

- Advantages of polypropylene K8303:Good mechanical properties, high heat resistance, long life 5-8 years, chemical stability.The surface smooth high strength, good toughness, corrosion resistant parts of piglets in farrowing crate deformation, bearing capacityThe utility model has the advantages of strong force, long service life, no fear of flame, and the use of a flame sterilizer.

- Q:Board PVC plastic floor plastic toxic

- PVC floor "refers to the use of polyvinyl chloride material production floor. Specifically to the polyvinyl chloride and its copolymerization resin as the main raw material, filler, plasticizer, stabilizer, coloring agent and other accessories, in the continuous sheet substrate, the coating process or by rolling or extrusion process and.

- Q:A floor tile, with a knife cut appear skin, turned out to be plastic, this is what floor tiles

- Should be PVC floor, also known as plastic floor. The skin that is wear-resistant layer. The raw material of this floor is polyethylene. Is a safe, environmentally friendly floor. Now kindergarten, hospital, store, KTV and many other places are using it. Price is to look at the wear-resistant layer and thickness of the. General PVC2.0 thick, 0.4 wear layer price is 80 (which is installed).

- Q:Plastic film on the floor for a long time with what method is easier to remove

- Is to use a blow machine to blow hot chicken, and then hit with cold water.When the cracks quickly opened on the line.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Wood Flooring, Wood PVC Flooring Plank, Vinyl Linoleum Floor

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords