PVC Foam Sheet and PVC Foam Panel Sheets for Cladding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 ft

- Supply Capability:

- 500000 ft/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

PVC Foam Sheet Introduction:

PVC Foam Sheet, a kind of high-tech product, is produced by special machinery and technology processing. The main material PVC resin can be foamed and extruded into a special sheet with many advantages, such as glossy or matt surface, waterproof, flame-resistant, UV stable, sound and heat insulation, anti-chemical corrosion, etc.

Kingstar PVC Foam sheet is manufactured by the equipment imported from well-known Italian Bausano Group and Austria Cincinnati Company. We, with more than 15 years' processing experience, have invented several formulas to ensure every piece of sheet could be perfectly used.

Features:

1. Light weight, easy and convenient to storage, transportation and use

2. It could be drilled, sawed, nailed, turned, glued, bended, printed, oiled, etc

3. Uniform fine & close cell structure

4. Hygienic, Rigidity, Durable

5. Perfect chemical corrosion resistance, good resistance to UV & weathering

6. Fire retardant and self extinguishing

7. Moisture-resistant, mildew proof, rot proof, low water absorption

8. Non-deformation, color fastness for a very long time

9. Sound insulation, sound absorption, heat insulation and heat preservation

10. Easily to put protective film on one or two sides

11. Smooth surface and suitable for silk-screen printing, laser engraving (must clean the surface before printing)

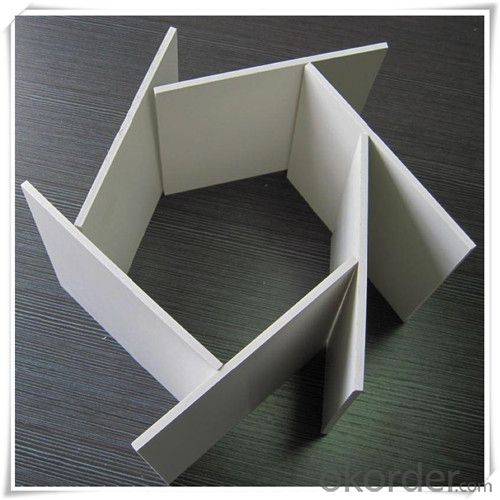

PVC Foam Sheet Details show:

Name | Density(g/cm3)±0.02 | width and length(mm) | Thickness(mm)±0.2 | Color |

PVC Foam Board | 0.8 | 1220*2440 | 1~25 | white,red, yellow, blue, green, gray, black |

0.6 | 2~25 | |||

0.5 | 2~25 | |||

0.8 | 1560*3050 | 1~10 | ||

0.6 | 2~10 | |||

0.7 | 2050*3050 | 1~10 | ||

pvc rigid sheet | 1.36-1.45 | 1220*2440 | 0.23-1.8 | |

2-5.8 |

Applications:

1. Advertising Signs, billboards, displays, exhibition stands

2. Screen printing, laser engraving

3. Thermoformed parts

4. Architecture, indoor and outdoor decoration

5. Furniture, kitchen & bathroom cabinet

6. Walls & partitions, wall cladding

7. Poolside furniture, swimming pool floor planking

8. Board for Chemical industry and laboratory equipment

9. Interior scaleboard for boat & ship, vehicle, train

Pictures:

FAQ:

Q: What's the PVC Foam Sheet Processing performance?

A: 1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

- Q:Recently we received a lot of customers to reflect, said to buy their own snowflake sheet, the results go back after use, the taste is great, even worse, the board labeled furniture has not long, there has been damp deformation situation. Customers are very angry, we are also confused.

- 1. Xuefeng every sheet, including the ecological board, wood panels, panels have snowflakes anti-counterfeit labels and security calls, it is recommended to buy a customer from the snow plate from the plate randomly selected several calls to verify its authenticity The 2. Xuefeng ecological board, woodworking board, in the side of the plate, will be marked with the corresponding stamp, including Hunan Xuefeng Building Materials Co., Ltd. honor produced, grade (E0 or E1), the factory date, factory code, and plate models. 3. Xuefeng panel, if it is E1 level, it will be posted in the corner of the panel snow Uncle's pattern, and clearly marked as E1-level decorative panels. Changsha snowflake flagship store welcome to report false snow products, and welcome everyone to Changsha flagship store to face criticism. We can come to the store smell the smell, that is, so many plates gathered in the place, the smell than other plate business to be much smaller.

- Q:Logs, lumber (square wood, plate, specifications) from what kind of tree species, what characteristics, mainly used for what type of wood structure, the specification is how to grade?

- Wood refers to the already skin, roots, treetops of wood, and has been processed according to a certain size into the diameter and length of the material. Sawn timber, also known as corridor, plate; that is, according to a certain standard specifications or size of the re-processing molding. Conifers, broadleaf trees (such as various types of pine, cedar, cypress, camphor, ash, etc.) can be processed into logs and sawn timber. Conifers generally trunk straight and tall, smooth texture, uniform material, high strength, bulk density and expansion shrinkage smaller, better corrosion resistance. Is the main building materials, can be used as load-bearing components, furniture and so on. Broadwood tree trunk straight part of the general is relatively short, hard material, more difficult to process, heavier, swelling, warping deformation, easy to crack. Often used as a smaller component. Some tree species are beautiful, suitable for interior decoration, furniture and plywood. Wood structure of the specification of the wood to allow the stress level and elastic modulus are clear values, it is recommended to consult the specification.

- Q:What are the types of boards on board?

- 94V0: Flame-retardant cardboard (die punch) 22F: Single-sided half-glass plate (die-punching) Fr-1 CEM-1 (mold punching) CEM-3: double-sided half-glass plate (in addition to double-sided cardboard outside the double-sided low-end material, a simple double-sided board can use this material (single-sided glass fiberboard (must be computer drilling, can not die) , Than the FR-4 will be cheaper 5 to 10 yuan / square meter) ...

- Q:Imitation marble pvc plate 1.5 thick

- 1, the process: the substrate is a mixture of calcium powder and PVC after a squeeze molding. Surface by thermal transfer process vacuum embossed imitation marble pattern, do uv fluorocarbon varnish. Imitation marble glass magnesium board, the substrate is glass magnesium board, alumina calcium oxide mixed material. Surface stickers are coated with marble. 2, specifications: uv imitation marble sheet general specifications is a single sheet 1200 * 2400mm, thickness of 3.8-4mm. Weight is generally between 21.5-23 kg. Imitation marble glass magnesium board leaflets specifications are generally 1200 * 2400mm, thickness of 5mm, the weight is generally about 30 kg. 3, features: a natural marble effect, clear lines, simulation results as high as 99.5% or more. Color uniformity, smooth surface, wear, hardness up to 5H-7H, easy to clean, resistant to pollution, B1 fire, no radiation, light weight, weight is one-fifth of natural marble, the price is. 4, use: instead of natural marble, widely used in a variety of architectural interior decoration. Hotels, office buildings, shopping malls, supermarkets, KTV, bars, cinemas, hot springs clubs, offices. Home improvement is mainly used for film and television background wall, sofa background wall, all kinds of Pass.

- Q:How to change the cabinet board is not Jilin forest workers dew river plate

- Plate above the logo, but even if the e1-level moisture-proof board also used a few years Kazakhstan

- Q:Is the cement pressure plate and the cement fiber board a plate? Is there a difference?

- Cement fiberboard and cement pressure plate is a product of two names, in fact no difference. The cementitious materials are cement, and the reinforcing materials are fibers (asbestos fibers and / or cellulose fibers). The name of the fiberboard emphasizes the reinforcement of the material 'fiber'; 'pressure plate' name emphasizes the production process, the use of presses on the board green pressure, squeeze out the water and compaction, improve the board's density and strength. 'Cement fiberboard' is a more traditional name, but in recent years is also known as 'cement pressure plate'. Advantages and Disadvantages of Cement Fiberboard Advantages: cement fiber pressure plate as a new environmentally friendly building materials, in addition to the function of the traditional gypsum board, but also has excellent fire performance and moisture resistance, the advantages of long life, a large number of industrial and commercial applications in the ceiling ceiling and partition, home decoration , Furniture liner, billboard liner, ship compartment board, warehouse floor, network floor and tunnel and other indoor works of the wall. Calcium silicate board processed into the ceiling, with resistance to subsidence, moisture, no dust, non-flammable and other characteristics, an effective solution to mineral wool board gypsum board easy subsidence, short life defects. Calcium silicate board, fiber cement pressure plate is the ideal decoration of the permanent building plate. Walls, ceiling also applies to the wall, the activities of the floor, table, billboards, goods cabinets, kitchen latrines, goods cabinets, fire Pipe, furniture liner, fire door lining. Disadvantages: easy to cause crevice cracking, and deal with the gap is too much trouble. (Thermal expansion and contraction is relatively strong in the reason)

- Q:Millet duck bathroom sheet durable?

- This product is the pioneer of smart bathroom, high-end products, but excellent quality, but also atmospheric fashion.

- Q:There are children at home, very concerned about this problem. Thank you, you have bought, the brand called Sharon Dick this is quite good.

- Solid wood furniture, formaldehyde content than the number of low-grade furniture, no specific indicators, generally much lower. Mainly affect the formaldehyde content of solid wood furniture is the paint part. Formaldehyde mainly from the glue, adhesives, paint and other processing to the part. House decoration because of formaldehyde and other factors caused by very hot eyes, the air is not clear and other conditions, solutions are: 1, ventilation, vacant for some time. 2, put in the house rotten apples, activated carbon, the effect is very good. 3, you can find a clear clear formaldehyde cleaning company. 4, put some flowers, you can absorb formaldehyde, but the flowers on the sacrifice. 5, the best way is to place 3 months, so that formaldehyde volatile.

- Q:What is the difference between acrylic and resin plates?

- Acrylic from English, the chemical name is abbreviated as: PMMA; PMMA, also known as polymethyl methacrylate, is made from acrylic monomer (pellet or liquid) MMA polymerization. Because the transparency is very high, can be as high as 93%, so it is also known as: plexiglass. Acrylic is not plastic, because the plastic is PVC collectively, from the use of acrylic terms: can be divided into: advertising materials, decorative materials, crafts materials. Resin board, also known as eco-resin plate (Ai Hao), chemical name: PETG PETG is a non-crystalline copolyester, PETG commonly used comonomer is 1,4-cyclohexanedimethanol (CHDM), all known as polyethylene terephthalate-1,4-cyclohexane Dimethanol ester. It is the product of polycondensation of terephthalic acid (TPA), ethylene glycol (EG) and 1,4-cyclohexanedimethanol (CHDM) by transesterification. Compared with PET, -cyclohexanedimethanol comonomer, with the PCT more than ethylene glycol comonomer, therefore, PETG performance and PET, PCT is very different. PETG sheet has outstanding toughness and high impact strength, the impact strength is modified polyacrylate 3 to 10 times, and has a wide processing range, high mechanical strength and excellent flexibility, compared to PVC transparency High, glossy, easy to print and have an environmental advantage.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Foam Sheet and PVC Foam Panel Sheets for Cladding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 ft

- Supply Capability:

- 500000 ft/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords