Pumping Cylinder(SCHWING) I.D.:DN250 Length:2325MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

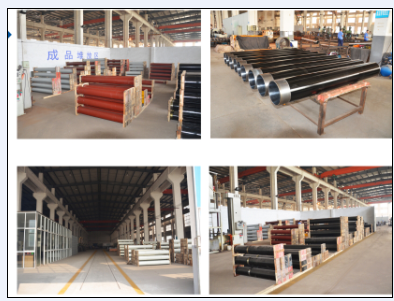

The Pumping Cylinder(SCHWING) I.D.:DN250 Length:2325MM normally made by steel material No. C45. according to customer’s requests, and also package in bundles or nude packing directly put into container.

Scope of Application of the Cylinders

The Pumping Cylinder(SCHWING) I.D.:DN250 Length:2325MM is a Cylinder pumping for combined use with other concrete pumps parts in concrete pumping operations. It can be widely used in the construction of various types of concrete structures like industrial and civil buildings, bridges, roads, and other types of infrastructure.

This Pumping Cylinder(SCHWING) I.D.:DN250 Length:2325MM can only be used in Schwing concrete pumps and Schwing truck pumps construction operations, but not in any other operations, like dragging, moving, or hoisting heavy articles or personnel. The Cylinder is also not allowed to be used in any location where any combustible or explosive material exists or a cave-in may occur.

Specifications:

Pumping Cylinder(SCHWING) I.D.:DN250 Length:2325MM

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230.DN250

3. Material: C45

4. quenching and tempering to improve the hardness to HB241-280

5. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

6. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

7. Capacity: 60,000~80,000cbm

Product Advantages:

OKorder's Cylinders DN250*2325 Channels are durable, strong, and safety.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days)

Reliable performance

Easy to weld

High safety.

· Professional Service

· Competitive pricing

Measuring of wall thickness from the outside

Low purchase cost

FAQ:

Q1: How long about delivery time about Pumping Cylinder(SCHWING) I.D.:DN250 Length:2325MM ?

A1: Normally we keep the raw materials for old customers and sometime we also keep stock products to make sure delivery time in any emergency cases.

Q2: How do we guarantee the quality of our Pumping Cylinder(SCHWING) I.D.:DN250 Length:2325MM ?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will book the vessel for goods. The specific shipping date is dependent upon international and government factors, but is typically10 to 30 workdays.

Q4: If we can produce some Pumping Cylinder(SCHWING) I.D.:DN250 Length:2325MM according to customers request?

A4: Yes, we can produce Pumping Cylinder(SCHWING) I.D.:DN250 Length:2325MM according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, If needed,

- Q:What are the types, classifications and specifications of concrete pump?

- In accordance with the export pressure rating label, divided into low pressure pump (5MPa), medium pressure and high pressure pump pump (6-10MPs) (>10MPa)

- Q:Are there any specific tools or equipment required for the installation of concrete pump spare parts?

- Concrete pump spare parts installation requires specific tools and equipment. The necessary tools include wrenches and sockets for bolt and nut tightening, hydraulic jacks for lifting heavy parts, and a crane or hoist for positioning extremely heavy components. To ensure secure installation, a torque wrench is used to tighten bolts to the correct torque specifications. Lubrication is achieved using a grease gun to apply grease to moving parts. Measuring tools like tapes or rulers are used for precise positioning and alignment. Safety goggles, gloves, and other protective gear should be worn during the installation process to prevent injuries. It is crucial to consult the manufacturer's instructions or seek professional assistance for proper installation, as the required tools and equipment may vary depending on the concrete pump's type and complexity.

- Q:How often should a concrete pump wear plate be replaced?

- A concrete pump wear plate should be replaced when it shows signs of significant wear and tear or when it starts to affect the performance and safety of the pump. The replacement frequency can vary depending on factors such as the type of concrete being pumped, the pump's usage, and the quality of the wear plate. Regular inspection and maintenance can help determine the appropriate replacement schedule.

- Q:Are there any specific regulations or standards for the labeling and packaging of concrete pump spare parts?

- Yes, there are specific regulations and standards for the labeling and packaging of concrete pump spare parts. These regulations ensure that the parts are properly identified, labeled, and packaged for safety, transportation, and ease of use. They may include requirements for clear identification of the part, its manufacturer, dimensions, and any necessary warnings or instructions. Additionally, packaging standards may specify the use of suitable materials to protect the spare parts from damage during shipping and storage.

- Q:Can concrete pump spare parts be replaced individually, or should they be replaced as a set?

- Concrete pump spare parts can be replaced individually, as there is no requirement to replace them as a set. This allows for more cost-effective and efficient maintenance, as only the specific part that needs replacement can be addressed.

- Q:How often should I replace concrete pump spare parts?

- The frequency of replacing concrete pump spare parts depends on several factors such as the quality of the parts, the intensity of usage, and the maintenance practices. However, as a general guideline, it is recommended to inspect and replace worn or damaged concrete pump spare parts on a regular basis, typically every 6 to 12 months, to ensure optimal performance and avoid potential breakdowns or safety hazards.

- Q:How does a concrete pump agitator motor prevent concrete from settling?

- A concrete pump agitator motor prevents concrete from settling by continuously rotating and agitating the mixture, ensuring that the aggregate, cement, and water remain well-mixed. This agitation action prevents the heavier components from sinking and settling at the bottom, maintaining a homogeneous consistency throughout the concrete.

- Q:Do concrete pump spare parts come with a warranty?

- Certainly, a warranty is provided for concrete pump spare parts. The duration of the warranty may differ depending on the manufacturer and the specific part being acquired. Typically, well-established manufacturers and suppliers offer warranties on their spare parts to instill confidence in customers regarding the product's quality and dependability. It is crucial to thoroughly examine the warranty's terms and conditions to comprehend the coverage and duration. Should any flaws or complications arise within the warranty period, customers can usually obtain a replacement or have the part repaired without incurring any additional expenses.

- Q:What are the advantages of using ceramic components in concrete pump spare parts?

- Using ceramic components in concrete pump spare parts offers several advantages. Firstly, ceramic materials are renowned for their exceptional durability and resistance to wear. Given the high pressure and intense forces that concrete pumps operate under, it is crucial to have components that can withstand such conditions. Ceramic parts possess superior hardness and strength, making them highly resistant to wear and extending the lifespan of spare parts. Secondly, ceramic components boast excellent corrosion resistance. Concrete consists of various chemicals and substances that can corrode metals. By utilizing ceramic parts, the risk of corrosion is significantly reduced, ensuring the longevity and reliability of the concrete pump spare parts. Furthermore, ceramic materials exhibit low friction coefficients. Consequently, when ceramic components are incorporated into concrete pumps, there is less friction between moving parts. This results in reduced energy consumption and increased efficiency. Ultimately, this can lead to cost savings and improved overall performance of the concrete pump. Moreover, ceramic parts possess high thermal resistance. Concrete pumps generate substantial heat during operation, which can potentially damage or deform certain components. However, ceramic materials can withstand high temperatures without compromising their structural integrity. This ensures the reliability and safety of the concrete pump. Lastly, ceramic components demonstrate excellent dimensional stability. They are less susceptible to expansion or contraction caused by temperature changes. This feature guarantees that spare parts maintain their shape and fit precisely within the concrete pump. Consequently, this precision fitting helps minimize leakage and maintain the pump's efficiency. In summary, the utilization of ceramic components in concrete pump spare parts offers exceptional durability, corrosion resistance, low friction, high thermal resistance, and dimensional stability. These advantages contribute to an increased lifespan, improved performance, reduced maintenance costs, and enhanced overall efficiency of the concrete pump.

- Q:Can concrete pump spare parts be installed by the pump owner or operator, or is professional assistance required?

- Professional assistance is generally required for the installation of concrete pump spare parts. The complexity and technical nature of these parts, along with the potential safety risks involved, necessitate the expertise of trained professionals. Attempting to install the spare parts without proper knowledge and experience could lead to improper functioning of the pump and even accidents. It is always recommended to seek professional assistance to ensure the correct installation and safe operation of concrete pump spare parts.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pumping Cylinder(SCHWING) I.D.:DN250 Length:2325MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords