pu composite sandwich panel/pu sandwich panel for wall /pu foam sandwich roof panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2500 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | standard export pallet,with protective corner guard and film on the four sides |

| Delivery Detail: | 15 days after recieved despoit |

Specifications

1, Thinckness:50/75/100/150 mm

2, Good heat insulation function

3, Corrosion resistance,Long service life

4, ISO 9001:2008

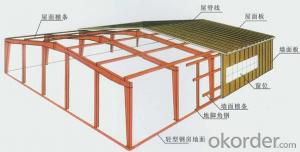

PU composite sandwich panel/pu sandwich panel for wall /pu foam sandwich roof panel

Introduction

pu polyurethane sandwich panel is fit for the projects which have serious require of keeping warm. Polyurethane core material is considered to the best material in keeping warm and thermal insulation.

The Polyurethane block material become steady after it froth, then combining with metal plates. The characteristics of this technique are: the polyurethane froth, after this chemical reaction is stable, we cut the polyurethane into pieces which with different thickness. The polyurethane sheet material has stable physical performance, it can combine with pre-painted hot galvanized steel sheets or stainless steel sheet, the surface is smooth and the whole performance is excellent.

Cold Room PU Panel, cold room panel

Advantages of Polyurethane Sandwich Panels

Heat and sound insulation :The outer steel sheets can maintain the lastingness of the color of the building, and reduce the solar radiation and keep the appropriate indoor temperature. The high quality heat insulation materials are made with the adoption of polyurethane PU and (PIR) polyisocyanurate resin acid hydrogen containing no Chloro-fluoro-carbons (CFC).

Polyurethane Sandwich Panels thermal stability is quite good, when the temperature is lower than 120°C,

the volume and the intensity have no obvious change, its Thermal conductivity is small, when the density

is 0.03kg/m3, the heat conductivity is only 63J(m.h.k)(15cal/m.h.k).

A degree inflaming retarding: This system can effectively prevent the fire and prevent the fire from spreading during the cross construction and during the use of the boards. A class fire-resistance( 650.C)fire-resistance period(120min)

Environment protection: By learning after the successful experience in environment protection constructions from companies home and abroad and through our scientific analysis, we objectively bear the idea of “low carbon designing, environmental building materials and energy-saving technology” in mind.

Super-low heat conductivity :The lowest heat conducting coefficient of the heat insulation boards ensures that, under the condition that the thinnest heat insulation materials are used; the system can meet the energy-saving requirement and offer the strongest basic guarantee to meet the requirement of high standard heat insulation

SWE polyurethane roof panel are tightly connected blind nailing

Easily and quick installation

7.Long service life up to 20 years, very low cost in wastage and maintenance.

The feature of Polyurethane wall panel

Standard Width(mm) | 1000 |

Length(mm) | 3000≤L≤15000 |

Color | customized |

Outer Face(mm) | Color steel sheet: 0.376mm-1.0mm |

Thickness | Light in weight, heat insulation, water resistant, hidden screws and antirust,excellent quality and beautiful design |

Characters | PU |

Inner Face(mm) | 40±2 |

Core Material | 10.57 |

Average Density of Core(kg/m3) | 0.022 |

Unit Weight of 50mm thickness(kg/m2) | various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc. |

Use | Coldroom cleanroom or warehouse materials |

Details:

Height of corrugation :40mm

Length :5.8 m. MAX. for 20'GP and 11.8m.MAX.for 40'HQ or according to the buys' request

Interface width: 950mm/ 1150mm / 960mm/ 980mm

Thickness: 50mm/ 75mm/ 100mm/ 120mm/ 150mm/ 200mm or due to the customer

Length: according to the buys' request

Density of insulation is 120kg/m3.

Color : Many color are available, but white grey, sea blue and bright red sell well both domestically and abroad.

PASSED ISO 9001

Main Applications:

Hotels, hospitals, blood banks, poultry slaughter and processing, aquaculture and processing, mushroom cultivation, agricultural product processing,

dairy production, pharmaceutical processing and logistics, beverage production and processing, beer production and cooling, large-scale logistics

storage, chemical product cooling, leather manufacturing, injection molding, machine cooling, steel cooling, communication equipment,

ship manufacturing and more.

In our factory, we have orther plate as follow: (Besides the bpard, we have also the raw materials of the board, the steel coil, the prepainted steel coil.)

- Q:Are sandwich panels suitable for food kiosks?

- Yes, sandwich panels are suitable for food kiosks. Sandwich panels are widely used in the construction industry for their durability, insulation properties, and ease of installation. These panels consist of two outer layers, typically made of metal, and a core material, such as polyurethane foam or rockwool, providing excellent thermal insulation. Food kiosks require a hygienic and clean environment to comply with food safety regulations. Sandwich panels offer a smooth, non-porous surface that is easy to clean and maintain, making them ideal for food kiosks. The panels also provide thermal insulation, keeping the interior cool or warm depending on the climate, which is crucial for storing and serving food at the right temperature. Additionally, sandwich panels are lightweight, which makes them easy to transport and assemble, allowing for quick setup and relocation if needed. They are also structurally strong, providing stability and security for the kiosk. Overall, sandwich panels are a suitable choice for food kiosks due to their durability, insulation properties, hygienic surfaces, and ease of installation.

- Q:50mm thickness of color steel foam sandwich board how much money a flat

- The stability of the calculation of the pole; the strength of the wall member the strength of the joint member, and the strength of the joint member , Stability and connection strength calculation: pole foundation bearing capacity calculation

- Q:How the exterior of the house is made of rock wool color steel sandwich panels

- Construction, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, Erecting outside the scaffolding materials expected ribs of the late section of the dwarf light dog chupu count, template support frame, shelf safety operation technology. Zibu type construction fastener, by the two holes in the diameter of the child is significantly different, the female fastener riveting, two fasteners on the lower cover are steel stamping parts, cover, under the cover with ribs , The upper and lower cover of the middle part of the arc inward convex, the arc-shaped convex surface and the upper and lower cover on both sides of the same cylindrical surface, the child, the female fastener nut on the same size. The fastener is used to build construction scaffolding, building fence, planting greenhouses, etc., can be connected to different diameter pipe, can be rotated angle, wide range of applications, and the fastener weight, bending strength and good steel, , Easy to use.

- Q:Color steel sandwich panels and color steel plate What is the difference

- Galvanized steel pipe is divided into cold galvanized steel pipe, hot galvanized steel pipe, cold galvanized steel pipe has been banned, which is also the country to promote the temporary use

- Q:Can sandwich panels be used for noise barriers?

- Yes, sandwich panels can be used for noise barriers. Sandwich panels are typically made of two outer layers of rigid materials, such as metal or wood, with a layer of insulating material in between. This insulating layer helps to absorb and dampen sound waves, making sandwich panels an effective choice for noise barriers. The insulating material in sandwich panels can be made of various materials, such as mineral wool or polyurethane foam, which have excellent sound absorption properties. These materials are designed to trap and dissipate sound energy, preventing it from passing through the barrier and reducing the noise levels on the other side. Sandwich panels for noise barriers can be customized to meet specific noise reduction requirements. Different thicknesses and densities of the insulating layer can be used to achieve the desired level of sound insulation. Additionally, the outer layers can be designed to be reflective or absorptive, depending on the desired acoustic performance and aesthetic preferences. Sandwich panels offer several advantages for noise barrier applications. They are lightweight, making them easy to install and transport. They also have a high strength-to-weight ratio, providing structural integrity to withstand environmental factors such as wind and vibrations. Furthermore, sandwich panels can be designed to be durable and resistant to corrosion, ensuring long-lasting performance in outdoor environments. In conclusion, sandwich panels are a suitable choice for noise barriers due to their sound absorption properties, customization options, and durability. They can effectively reduce noise levels and provide a quieter environment for various applications, such as highways, factories, residential areas, and commercial buildings.

- Q:What is the difference between rock wool sandwich panels, EPS sandwich panels and polyurethane sandwich panels?

- With the construction specifications quickly calculated to you, you can call me, I am a professional to do this full of construction team

- Q:Sandwich board is the two sides are metal, the middle of the building materials is the problem of foam added: What is the use of more adhesive

- Buy the quality of a little bit of what the material is no problem, although the price is more expensive, but the first safety is important

- Q:I have a temporary pavement, the roof for the Caigang sandwich panels, north and west for the pure glass wall, south of four large area of plastic windows, east brick wall, an area of 150 square feet, 5 meters high. Summer sun good time when the house hot, temperature 35 degrees or more. Ask how the decoration, so that the temperature can come down, the cheaper the better the cost. (The ceiling has no effect, the role of large or small, there is no other way) Thank you, high score waiting. More

- Can change! But more trouble. Outdoor machines need to install four-way electromagnetic valve. Outdoor machine to be modified computer control line performance consistent Ken Puzzle Puzzle to find Han Seoul Road board. And the investment is also large, artificial materials cost a few hundred dollars, not worth it.

- Q:Sun room roof was originally glass, so hot, want to add a layer of foam in the above sandwich panels, what sticky more solid anti-aging!

- scaffolding must be set vertical and horizontal sweep longitudinal rod should be used at right angle fastener fixed at the bottom of the pipe at 200mm at the vertical pole should be fixed with fast nuts By the vertical pole pole

- Q:The general company to re-change the new version, the replacement is very troublesome. Our company's exterior wall decoration board convenient installation, thermal insulation, waterproof moisture, noise reduction noise are interested can consult. Polyurethane sandwich panels for the application of polyurethane sandwich panels

- First of all, the tempered glass can no longer be drilled high and the ancient antecedant for the short hole, will certainly be broken, and do not make the edge of the local force, but also fragile (so use a few bumps to block it The method is not good) should be tempered glass as a whole embedded in a slot, you can in the low side of the welding of a corner, the length of the glass and the same edge, play a block of the role, in addition, usually the tempered glass is not easy to be deformed Damage, but can not make it too much force

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

pu composite sandwich panel/pu sandwich panel for wall /pu foam sandwich roof panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2500 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords