Poly 220W Solar Panel / 30vmp with Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Item specifice

Material:

Polycrystalline Silicon

Max. Power(W):

220

Number of Cells(pieces):

60

Product Description

220W Poly Crystalline Solar Panel

Product Highlights:

1. Guarantee positive power tolerance (0~+3%)

2. Module can bear snow loads up to 5400Pa and wind loads up to 2400pa

3. High performance under low light conditions (cloudy days, mornings and evenings)

4. Certified by Europe standards of TUV, IEC, CE and British MCS and AUS CEC

5. OEM/ODM available

Specs

| Electrical Characteristics | |

| Maximum Power [Pmax] | 220W |

| Power Tolerance | +/-3% |

| Maximum Power Voltage [Vmp] | 29.00V |

| Maximum Power Current [Imp] | 7.59A |

| Short-Circuit Current [Isc] | 8.38A |

| Open-Circuit Voltage [Voc] | 36.4V |

| Module Efficiency | 13.52% |

| Max. System Voltage | 1000VDC |

| Cell Size and Series | Poly 156*156 60pcs (6*10) |

| Temperature Coefficient of Pmax | - 0.47% / º C |

| Temperature Coefficient of Voc | - 0.33% / º C |

| Temperature Coefficient of Isc | 0.05% / º C |

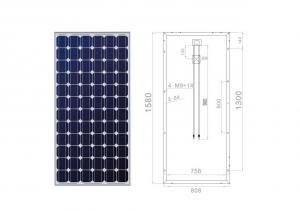

| Mechanical Characteristics | |

| Dimension (mm) | 1640*992*40 |

| Frame | Anodized Aluminium Alloy |

| Glass | 3.2mm,High Transmission,Tempered Glass |

| Junction box & Cable | IP65 Rated weatherproof connectors Cable: TUV 1x4.0mm2 / UL12AWG,Length:900mm |

| Weight | 19.0Kgs |

Industry-leading Warranty:

Warranty on material and workmanship: 10 years

Guaranteed output of 90% after 12 years and 80% after 25 years.

- Q:Are there any disadvantages to using solar panels?

- Yes, there are a few disadvantages to using solar panels. Firstly, the initial installation cost can be relatively high, making it a less affordable option for some individuals or businesses. Additionally, solar energy production relies on sunlight, which means that solar panels are less effective during cloudy or rainy days, or at night. This intermittency requires a backup energy source or energy storage system, adding to the overall cost. Moreover, solar panels require a significant amount of space for installation, which may not be feasible in densely populated areas. Lastly, the manufacturing process of solar panels can have environmental impacts, as it involves the use of certain materials and chemicals. However, it is worth noting that continuous advancements in technology are reducing these disadvantages, making solar panels an increasingly viable and sustainable energy solution.

- Q:I think that solar panels are the future and i think that the conventional way of generating electricity is going to be replaced by solar panels. I would like to be part of this industry as an entrepreneur but i do not know how to since i do not have a technical background. I would like to sell solar panels to consumers and to business. Should I start a manufacturing company that manufactures solar panels? Should I buy solar panels from manufactures and sell them to consumers? What should I do?

- HEAR IS A WAY, BY CLICKING THE LINKS $$GET PAID $$GET PAID $200+EURO 200 INSTANT $$ $$SINGUP BONUS $$ GET PAID BY CLICKING BELOW FOLLOW THE INSTRUCTIONSFIRST CLICK THE LINK ONE AND REGISTER YOUR SELF, AND THEN CLICK THE LINK TWO AND REGISTER YOUR SELF CLICK AND GET THE LINKS:

- Q:Can anyone tell me how to connect a solar panel from a calculator to a motor from an RC car.

- can increase your voltage from a single solar panel. In combination with a large capacitor, you could deliver short bursts of power to the motor which would allow intermittent operation.

- Q:Can solar panels be installed on asphalt shingles?

- Yes, solar panels can be installed on asphalt shingles. However, it is important to ensure that the shingles are in good condition and can support the weight of the panels. Proper installation techniques and mounting systems designed for asphalt shingles should be used to prevent any damage to the roof.

- Q:How do solar panels affect the local job market?

- Solar panels can have a positive impact on the local job market. Their installation and maintenance can create new employment opportunities in the renewable energy sector, leading to job growth. Additionally, the development of solar farms and manufacturing facilities can attract investments and create more jobs in the local economy.

- Q:OK, so if you put solar panels up on a roof, they are busy turning the sun's energy into electricity. So, does that mean the roof (and therefore the house/structure) stays cooler as well? Or does it still get hot, because . . . I dunno, maybe the panels don't convert all the energy, and the spillover still heats up the building.Any links or URLs to scientific answers would be appreciated, but I don't mind hearing from the Average Joe or (Joelle).

- The type depends upon what you want the solar panels to do. Generate electricity ? Heat gain? Makes a big difference. You should probably get a contractor who specialises in solar panels out to at least start your education on this subject or you could throw a lot of money away on something you don't really need or want.

- Q:Making a solar panelI know there was a recommended wattage for the soldering iron but i cant rememberdoes anyone know?

- Rosin okorder /

- Q:What is the impact of roof pitch on solar panels' efficiency?

- The impact of roof pitch on solar panels' efficiency is significant. The pitch, or angle, of a roof determines how much direct sunlight the panels receive and how effectively they can convert that sunlight into electricity. In general, a roof with a steeper pitch allows for better solar panel performance as it maximizes exposure to sunlight and minimizes shading. However, if the roof pitch is too steep, it can increase wind resistance and make installation more challenging. Therefore, it is crucial to find the optimal balance between roof pitch and solar panel efficiency to ensure optimal energy production.

- Q:Can solar panels be used in areas with high levels of pollution from industrial activities?

- Yes, solar panels can be used in areas with high levels of pollution from industrial activities. While pollution can have some impact on the efficiency of solar panels, they are still able to generate electricity even in polluted areas. Regular cleaning and maintenance of the panels may be required to ensure optimal performance. Additionally, installing solar panels in such areas can help offset some of the carbon emissions from industrial activities, contributing to a cleaner and more sustainable energy future.

- Q:I want to buy a solar panel kit but I'm unsure of how it works. Basically I want to run my entainment set, Xbox, cable box, 46 led tv, and some desktop speakers. I went online and found a kit for like 250 or something like that at homedepot and was wondering if that kit is worth the money or go bigger or something.

- Solar panels use light energy (photons) from the sun to generate electricity through the photovoltaic effect. The structural (load carrying) member of a module can either be the top layer or the back layer. The majority of modules use wafer-based crystalline silicon cells or thin-film cells based on cadmium telluride or silicon. The conducting wires that take the current off the panels may contain silver, copper or other non-magnetic conductive transition metals.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Poly 220W Solar Panel / 30vmp with Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords