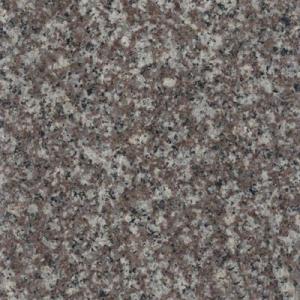

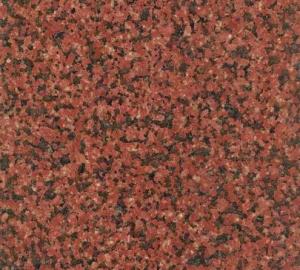

Polished G664 Granite Stone with 1-5cm Thickness for Slab, Tile

- Loading Port:

- Xiamen

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m³

- Supply Capability:

- 30000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1 Structure of Granite Countertop/Slab Description

We manufacture various designs of angel tombstones and carved monuments headstone, which are popular around the world. We have professional CAD team, welcome any customed design and size from you. We would supply best service, fast shipping for each client.

2 Main Features of the Granite Countertop/Slab

Various color for choice, welcome customed shape and size, professional CAD team

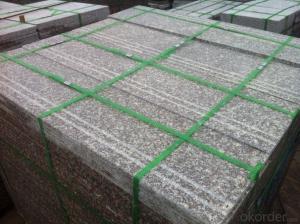

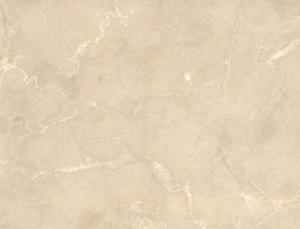

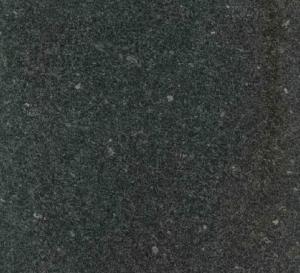

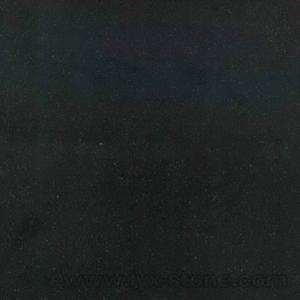

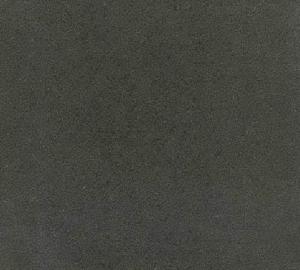

3 Granite Countertop/Slab Images

4 Granite Countertop/Slab Description

1)Material: Chinese Domestic Stone and Imported Stone

2)Standard Size:

Headstone: 17"x20", 24"x30", 30"x36", 42"x22", 48"x28", 60"x28", etc.

Basement: 23"x12", 34"x12", 42"x12", 48"x14", 60"x14", 66"x12", etc

3) Standard Thickness: 60mm, 80mm, 100mm, 120mm, etc.

4) Finish: Honed, Flamed, Polished, Sandblasted, Bush Hammered, Chiseled, etc.

5) Edges: Full Bullnose, Half Bullnose, Flat Eased (Eased Edge), Bevel Top, Ogee Edge, Dupont, etc.

6) Hot Colors: Absolute Black (Shanxi Black), China Black, India Black, G603, G635, G664, G687, G562, G654, China Multicolor Red, Bahama Blue, Paradiso, Multicolor Red, Butterfly Blue, Blue Pearl, Aurola, India Red etc.

7)Tolerance of Granite

Thickness: ±2 MM or as customized

Polished Degree: Above 90+or as customized

5 FAQ of Granite Countertop/Slab

1) How to control the products’ quality?

We have always placed great emphasis on quality control to ensure that excellent quality level is maintained. Moreover, the principle we always maintain is "to provide customers with better quality, better price and better service".

2) Can you provide OEM service?

Yes, we work on OEM orders.

3) What information should I let you know if I want to get a quotation?

1, Size

2, Color Number(if have)

3, Package

4, Quantities

5, Please send us some pictures for checking if possible so we can do best as your request. Otherwise, we will recommend relevant products with details for your reference.

4) How many days will sample be finished and how we control the sample charge?

Samples will be sent within 5 working days after we are in receipt of the payment. The sample charge is free, but the charges of shipping will be paid by the customer. You can pay the shipping charges by telex transfer(T/T),Payeasy.

- Q:Characteristics of white hemp granite

- White linen is a kind of granite, is an acidic igneous rock, the main component of silica, more than 70%. Texture is relatively hard, Shore hardness of 100 or more.

- Q:What are the types of granite

- Electrical granite colors are varied, except for colorless and white, which is extremely rare. This granite type is ideal where there is not much traffic because it is all types of soft. Note: When selecting granite, it is best to distinguish between materials by some companies according to the color of the granite classification. The type of granite divided in this way may have more than 100 kinds of granite.

- Q:Granite Marble with what medicine is polished

- 1, the construction process: stone surface finish surface cleaning → stone gap marble glue repair → overall ground grinding 6-7 times → ground drying → ground crystal treatment (K2, K3 syrup) → overall ground conservation (K1 syrup) → ground Clean up. 2, the stone surface to complete the surface clean up: the stone before the crystallization of the ground processing, paving finish the overall surface formation, no color, each stone between the diagonal flush, the ground to clean up the whole, with dry and clean to drag clean, No sand on the ground, impurities. 3, stone gap marble glue repair: stone surface after the completion of the overall clean-up, with marble glue on each piece of stone above the small spots to repair, first of all the original damaged surface with the stone color of the marble glue to repair. And then use a special stone sewing machine on the original stone installation of the seam in the re-neat cutting slit, so that the width of the gap changed almost, and then close to the stone color of the marble glue to fill it (Note: If the past has been done in the seam Processing without the need for new openings). Venom glue must be repaired after the glue can be done under the next process.

- Q:What does the granite mean?

- Granite structure is uniform, hard texture, beautiful color, is the quality of building stone. Compressive strength varies according to the variety and origin of stone, about 1000-3000 kg / cm. Granite is not easy to weathering, beautiful color, the appearance of color can be maintained for more than a century, because of its high hardness, wear resistance, in addition to the use of high-level architectural decoration works, hall floor, or open-air carving of the preferred material.

- Q:How to get rid of the cement traces of granite stone

- Can be dipped in some white vinegar to scrub, and then scrubbed with water, and then wax protection can make the stone to keep clean, bright. Tell you this situation, I generally use oxalic acid to deal with, the effect is very good. Such as outdoor ground pavement granite, litchi noodles and fire surface of the stone in the construction, the purchase of vats of oxalic acid (liquid) fell on top of the stone, the operator to bring a good rubber gloves, with high density sponge sticks repeatedly scrub, cement The mortar will soon be cleared. And then rinse the ground with water on the OK. I am building a large area of the square are using this method of cleaning.

- Q:The difference between granite and fire board

- Fire board - a method of processing granite, the first natural granite saw the plate, the surface of the plate after the initial grinding, after the first mill on the fixed frame, and then the surface of the first grinding flame burning Which is characterized in that the flame is sprayed with acetylene, oxygen and spray gun, and the flame moves evenly on the board surface at a speed of 120 to 250 mm per second and the distance between the nozzle and the board is 20 to 40 mm and Inclination, the flame temperature of 800 ~ 1000 ℃, the flame before the first spray on the plate before the water (to prevent the flame burning burned plate, the water heat absorption heat absorption)

- Q:What are the rocks?

- Granite is mainly composed of quartz, feldspar, hornblende, pyroxene, olivine, mica and other mineral components. Mohs hardness of 6 degrees or more, Shore hardness between 60-90, gloss and color and mineral composition There is a great relationship, can be described as ever-changing.

- Q:Why granite is not fireproof

- Granite is not refractory for the following reasons: 1, the content of natural granite magnesia is higher, easy to oxidize the oxygen and chemical reaction of oxygen, 2, granite fire will burst open, and soon lost normal physical and mechanical functions.

- Q:What type of rock is the granite?

- Magmatic rocks are also called igneous rocks, magma formed in the depths of the crust or in the upper mantle, formed in the upper part of the crust or ejected to the surface to cool and consolidate and crystallize. Because the conditions it generates are very different from sedimentary rocks, its characteristics are also significantly different from sedimentary rocks.

- Q:What is the density of granite?

- Granite (Granite), the main component of the continental crust, is a kind of magma in the surface below the formation of the formation of igneous rocks, the main component is feldspar and quartz.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polished G664 Granite Stone with 1-5cm Thickness for Slab, Tile

- Loading Port:

- Xiamen

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m³

- Supply Capability:

- 30000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products