Phenolic Foam/Polyurethane Sandwich Panel Production Line

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Phenolic Foam/Polyurethane Sandwich Panel Production Line

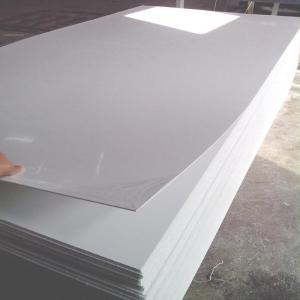

Introduction of the Equipment

Phenolic Foam/Polyurethane Sandwich Panel Production Line is a professional machine for manufacturing Sandwich Panels of which the core material is phenolic foam or polyurethane and of which both layers is embossed aluminium foil or colored steel. The thickness of sandwich panel is 20-200mm, the width 1200mm and the length according to customers’ request. The sandwich panels are used as the air ducts in Central air conditioning. The machine can used to make other insulation panel as long as the surface material is changed. The working principle of the machine is as below: mix the raw materials with a certain ration in a container and then pour the mixture on the interlayer of the sandwich panel. Then the raw materials has the chemistry reaction of foaming and solidifying. In the end the automatic tracking cutting machine cuts the panels into a certain length.

The Components and Its Function

The components include: the aluminium foil embossing machine, the raw material distributor, the aluminium foil/colored steel pre-heating installation, the material-baffling mechanism, the automatic tracking cutting machine, the roller supporters and brackets. All the components can be individually adjusted.

The Aluminium Foil Embossing Machine

The embossing machine include three parts: the charging unit, the embossing unit and the windin unit. It is used to emboss figures and logos under certain surface tension on the aluminium foil (Width: 1200mm, thickness: 0.08-0.12mm).

The Raw Material Distributor / The Raw Material Charging Unit

This device is installed at the forefront of the production line and the laminator. It can adjust the location and control the surface tension of the aluminum foil and the colored steel before entering the laminator.

The Aluminium Foil/Colored Steel Pre-heating Installation

Before entering the injection machine, the temperature of the aluminum foil or the colored steel must meet the requirement of the foaming technology of the PF or PU. And thermodynamic cycle device on the production line can control the temperature of the aluminum foil or colored steel.

The Material-baffling Mechanism

The material-baffling mechanism is used to stick Kraft paper to both sides of the lower aluminum foil before entering the injection machine. So there is a enclosed area between the upper aluminum foil and the lower one. With the Kratf paper, there will be no leakage of the raw materials when the machine is working.

The Reaction Injection Machine

The reaction injection machine is used to calculate the computation and mix of raw materials pro rata. In order to make the temperature of the raw materials meet the requirement of the foaming technology, the machine is equipped with heating, refrigerating and temperature control devices. In addition, People can control the pressure, the computation of the raw matrials by this machine. And the process of injection, cleaning and sweeping are automatically controlled. The equipment is equipped with three tanks, two for resin materials, one for curing agent material.

The Back-and-forth Injection Machine

This machine is used to apply the mixture on the lower aluminum foil or the colored steel. The injection head is drived by fluid drive, and its speed, moving frequency, transverse moving distance is adjustable.

The laminating conveyor is used for the laminating and the shaping of the sandwich panel. This machine adopts the driving structure of drag chain. The chain is made of fine aluminum alloy and is 18m long. The moving speed is 3-8m/min and is controlled by frequency conversion. If the customers want to improve the moving speed, they can customize a longer conveyor. The thickness is controlled by the space between the upper link plate and the lower one. The startup of the link plate is control by fluid drive. The 12 tilt cylinder is adjustable so that the link plates can stops at any position.

The Heated Air Circulation Device

To meet the expected requirement of foaming technology, the production line is equipped with a heated air circulation device. Its used to heat the link plates to 70℃. Its made up of one hot blast stove, one diesel-oil-drived stove and two temperature sensors. The temperatue sensors are placed at the inlet port and inside the conveyor so the operator can monitor the temperature fluctuation.

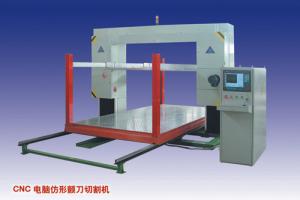

The Automatic Tracking Cutting Machine

The panels are cutted into different lengths by this machine.

MAIN TECHNICAL PARAMETER OF THE PRODUCTION LINE

Specification of Sandwich Panel | Width*Thickness (mm) | 1200×(20~200) |

The Production Speed | m/min | arbitrary |

The Embossing Speed | m/min | ≤20 |

The Mixing Speed | round/min | 4500 |

The Moving of Injection Head | times/min | ≤80 |

The Max temperature of the heated air circulation device | ℃ | 70 |

The Laminating Length of the Conveyor | M | 18.82 |

The Max start-up Speed of the Conveyor | mm | 300 |

Total Power | KVA | 85~125 |

The Specification of the Production Line | mm | 40950×5620×3700 |

The Specification of the Embossing Machine | mm | |

Weight | T | ≈34 |

Note: The above information is for our standard production line and we can make it according to customers request. We will send our techician to our customers to install and debug the machines.

- Q:Conference hall sound insulation design, material purchase? Need to pay attention to what?

- If you only do conference hall and no other use (such as multi-function hall), do not need special attention, as long as the designer according to the overall design style to choose acoustics decorative materials on it

- Q:What is the great contribution of chemistry to mankind in the 21st century? Such as title

- The trend of penetration of chemistry into other disciplines will become even more pronounced in the 21st century

- Q:What is the fruit of the MOSO fruit and vegetable raw material

- MOSO fruit and vegetable is the world's five best fruit ratio of the model

- Q:Some houses in the United States have their own garden, their own fences, and then white paint, I would like to know what is the white paint material. The RT ~~~

- According to reports, benzene compounds have been identified as a strong carcinogen by the World Health Organization People in a short time to absorb high concentrations of toluene, xylene, there will be symptoms of central nervous system anesthesia, light dizziness, headache, nausea, chest tightness, fatigue, confusion, serious coma, so breathing, circulatory failure And death Benzene mainly on the skin, eyes and upper respiratory tract have a stimulating effect, often exposed to benzene, the skin may be due to degreasing and dry, scaling, and some allergic eczema The epidemiological survey conducted by US experts showed that the incidence of Alzheimer's disease was significantly higher among workers exposed to pain And in recent years a lot of labor hygiene data show that: long-term exposure to benzene mixture of workers, a higher incidence of aplastic anemia The The The The White paint is a material, this material can be used in different construction process coated on the surface of the object, the formation of strong adhesion, with a certain strength, continuous solid film The film thus formed is called a coating film, also known as a paint film or a coating "Belongs to the organic chemical polymer materials, the formation of the coating is a type of polymer compounds In accordance with the modern classification of chemical products, paint is a fine chemical products Modern coatings are gradually becoming a class of multi-functional engineering materials, An important industry in the chemical industry

- Q:Seeking energy-saving principle of multi-function air conditioning host energy saving device The

- On the contrary, the difference between the evaporation pressure and the condensing pressure is reduced, the pressure difference of the compressor is reduced, and the power consumed by the motor is reduced, but the cooling capacity is increased

- Q:Recently heard that Sotecomus company launched a multi-functional mortar spraying machine, what kind of, than ordinary spray machine have any advantages?

- The machine can use any material with a particle size of 5mm, a condensation time of 60 minutes and a density suitable for passing through the hose

- Q:What are the room soundproofing materials? Room sound insulation material purchase

- More and more attention to personal privacy now, noise has always been the focus of attention

- Q:Small lead down shape is simple, the best mold material can be cast molding, with strong strength and high temperature performance. Thank you in addition to metal, can not use high temperature gypsum or other materials production.

- no matter how good you can use NAK80 die steel

- Q:Upstairs health asked what kind of material leakage with smashed brick

- It is recommended that you choose the product of Dongfang Yuhong good Shi Tu 100 high elasticity waterproof acrylic waterproof coating good Shi Tu 100 high elasticity acrylic waterproof coating is based on high-quality modified acrylic multi-copolymer polymer emulsion as the base material, add a variety of help Agent, filler material from the scientific processing of a thick one-component water-based polymer waterproof coating material

- Q:Explain in detail, there are told me that this is used to doing, can be used in home improvement?

- But also by a special SANALIM (scattered Nailin) anti-bacterial treatment, making this kind of sports ground system to maintain long-term clean

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Phenolic Foam/Polyurethane Sandwich Panel Production Line

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords