Masking Tape Green Color 160 Micron SGS&ISO9001 Certificate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description

The Masking Tape is of crepe paper as the carrier, coating with rubber adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

General purpose of Masking Tape: widely used for paint masking, furniture, shoe material production, automobile painting, light duty packaging etc.

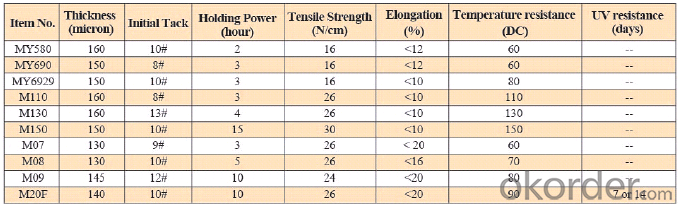

Typical Physical Reports of PVC Electrical Tape

Packaging

The thickness of the tape can be customized.

Cut Roll: As per customer’s requirements

Log Roll: Length 1800mm; width according to customers’ requirements

FAQ of Double Sided Tissue Tape

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Masking Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q:Can packaging tape be used for sealing plastic lunch boxes?

- Indeed, plastic lunch boxes can be sealed using packaging tape. This type of tape is crafted to possess formidable strength and adhesive capabilities, rendering it appropriate for sealing a wide array of materials, plastic included. Its capacity to provide a secure seal ensures that the contents of the lunch box remain fresh and safeguarded. Nevertheless, it is crucial to acknowledge that using packaging tape on plastic lunch boxes may result in residue or surface damage upon removal. To avoid such complications, it is advisable to employ tape specifically engineered for sealing food containers or explore alternative methods such as rubber bands or clips, which are designed to secure plastic lunch boxes without causing any harm.

- Q:What are the considerations for using packaging tape on temperature-sensitive items?

- There are several factors to consider when using packaging tape on temperature-sensitive items. To begin with, selecting the right type of packaging tape is crucial. Temperature-resistant tapes are specifically designed to withstand extreme temperatures. These tapes are made with materials that can endure high or low temperatures without losing their adhesive properties or distorting. It is important to choose a tape that is suitable for the temperature range the item will be exposed to during storage, transportation, or any other handling processes. Properly storing the packaging tape is also essential. Extreme temperatures can affect the tape's adhesive properties, making it less effective. It is advisable to store the tape in a climate-controlled environment, away from direct sunlight or areas with excessive heat or cold. This will help maintain the adhesive strength and overall quality of the tape. Additionally, ensuring that the surface is clean and dry when applying packaging tape to temperature-sensitive items is important. Moisture or dust particles on the surface can compromise the tape's adhesion and result in inadequate sealing. Preparing the surface properly will guarantee a secure and reliable bond between the tape and the item. Furthermore, it is crucial to consider the duration of exposure to extreme temperatures. If the item will be subjected to high or low temperatures for a long period, additional protective measures such as insulation or specialized packaging materials may be necessary to provide extra insulation. Lastly, testing the tape's performance before using it on temperature-sensitive items is essential. Conducting a small-scale trial or using a sample item can help determine if the tape is suitable for the specific temperature conditions. This will help identify any potential issues or limitations before using the tape on valuable or delicate items. In conclusion, by taking into account factors such as tape selection, proper storage, surface preparation, duration of temperature exposure, and performance testing, one can ensure the safe and secure packaging of temperature-sensitive items.

- Q:Can packaging tape be used for securing cables or cords?

- Indeed, cables or cords can be secured using packaging tape. Although it may not be the optimal option, particularly for prolonged or demanding uses, packaging tape can temporarily fasten cables or cords. This can aid in preventing entanglement or obstruction, particularly during transportation or storage. Nevertheless, it is crucial to acknowledge that packaging tape is not specifically designed for cable management. Consequently, it may not offer the same level of resilience or versatility as specialized cable ties or straps. For enduring or heavy-duty cable management, it is advisable to utilize products explicitly created for that intent.

- Q:What is the purpose of packaging tape?

- Packaging tape serves the purpose of securely sealing and reinforcing packages, boxes, or containers during storage, transportation, or shipping. Its design ensures a strong and long-lasting bond that keeps the package contents intact and protected. Furthermore, it acts as a clear indicator of tampering, allowing for easy identification of any unauthorized opening or interference. Additionally, it safeguards the package from dust, moisture, and other external elements, thereby maintaining the integrity and quality of the enclosed items. In summary, packaging tape plays a crucial role in providing a dependable and efficient solution for sealing and safeguarding packages, making it an indispensable tool for businesses, individuals, and organizations engaged in shipping and logistics.

- Q:What are the common color options for packaging tape?

- Packaging tape manufacturers and the intended use influence the range of color options available. Nevertheless, clear, brown, white, and tan are among the most frequently found colors. Clear tape is transparent, allowing visibility of package contents. Brown or tan tape, often referred to as brown tape, is widely chosen for its strong and secure sealing capabilities. White tape is commonly used for labeling, as it enables easy writing or printing of information. Additionally, packaging tape comes in various other colors, such as red, blue, green, and yellow, which can serve purposes like color-coding or enhancing visual appeal. Ultimately, the choice of packaging tape color is determined by personal preference, branding requirements, or specific organizational needs.

- Q:Can packaging tape be used for sealing plastic wrap?

- No, packaging tape is not typically used for sealing plastic wrap. Packaging tape is designed to adhere to cardboard and other surfaces, providing a secure seal for packages. On the other hand, plastic wrap is a thin, transparent film used to cover and protect food or other items. It is typically sealed by pressing the edges together or using a specialized plastic wrap cutter. While packaging tape may provide a temporary seal, it is not designed for use with plastic wrap and may not provide a secure or long-lasting seal. It is recommended to use the appropriate method for sealing plastic wrap, as specified by the manufacturer.

- Q:Is packaging tape resistant to chemicals?

- Yes, packaging tape is typically resistant to chemicals. It is designed to withstand various substances and maintain its adhesive properties, making it an effective choice for securing packages and protecting their contents.

- Q:Can packaging tape be used for sealing packages with breakable items like ceramics?

- Yes, packaging tape can be used for sealing packages with breakable items like ceramics. However, it is important to ensure that the tape is applied properly to provide adequate support and protection for the fragile items. In addition to using packaging tape, it is recommended to use additional protective materials such as bubble wrap or foam padding to cushion the ceramics and minimize the risk of damage during transit.

- Q:Can packaging tape be used for sealing packages for shipping?

- Indeed, packaging tape serves the purpose of sealing packages intended for shipping. With its specialized design, packaging tape effectively secures packages, guaranteeing their integrity throughout the transit process. It establishes a robust and long-lasting connection that can withstand the challenges posed by shipping and handling. Whether you're dispatching small or large packages, packaging tape becomes a vital instrument to guarantee the proper sealing and safeguarding of your items as they embark on their journey.

- Q:Is packaging tape safe to use on ceramic tiles?

- Yes, packaging tape is generally safe to use on ceramic tiles. Packaging tape is designed to adhere to a variety of surfaces, including ceramic tiles. However, it is important to ensure that the tape is removed carefully to avoid damaging the tile or leaving any residue behind. It is recommended to test a small inconspicuous area first to ensure that the tape does not cause any damage or discoloration. Additionally, it is always a good idea to follow the manufacturer's instructions and guidelines for using packaging tape on specific surfaces.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Masking Tape Green Color 160 Micron SGS&ISO9001 Certificate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords