Manhole Cover Heavy Duty Base with Round Cover

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Ductile Iron Manhole Cover Description :

A manhole cover sits on metal base, with a smaller inset rim which fits the cover. The base and cover are sometimes called "castings", because they are usually made by a casting process, typically sand-casting techniques.

Advantages: Good compressive, bending and impact strenth,anti-corrosion, not rust, long service life(at least 30 years). The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than. Contain no metal and no recovery value, anti-theft.

2.Main Features of the Ductile Iron Manhole Cover:

•High endurance

•High Strength

•Pressure Resistence

•Anti-corrosion

•Anti-theft

•Good visual effect

Safety options

There is no metal contain, directly reducing potential accident or further maintenance costs caused by thieves. Anti-slip surface offer a safe road condition even in extreme weather.

Light weight

Compared with cast iron manhole cover, FRP manhole cover is 30% lighter.

Light weight allows more loading per vehicle, more convenient transportation and economical savings.

Allows a safer working condition, which single workers is enough for installation without risk of injury.

Long service life

Strong resistance of acid, alkali, weathering, anti corrosion of water, dust, manhole covers used for gas are well sealed which prevent poisonous gas leaking.

Temperature tolerance is at the range of -40°C-200°C.

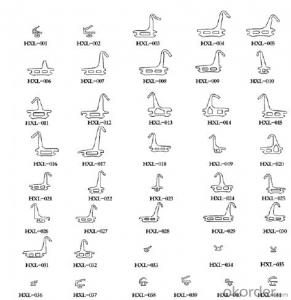

3.Manhole Cover Images:

4.Manhole Cover Specifications:

1) Production information

Manhole cover are manufactured for construction and public use. Manhole cover shall be smooth and free sand holes, blow holes, distortion or any other defects

2) Material

A) Ductile iron GGG50

B) Grey iron GG20

3) Designs

A) EN124 Class B125 C250 D400 F 900, with different size and grammage, or as customers' requirement.

B) as per customers' drawing or samples

5.FAQ:

Q. I have a heavy traffic manhole cover but it has been broken by a forklift, why?

A. Forklifts have solid wheels which apply pressure differently to standard pneumatics and therefore covers must be specially adapted to suit this.

Q. I’ve measured my clear opening size but none of your covers match it, can you offer anything?

A. It’s likely that your cover is quite old and in imperial measurements which are no longer manufactured. However, we can offer bespoke solutions with manhole covers made to the specification you require.

Q. The project I’m working on requires a manhole cover with a quality finish, what’s available?

A. Naturally, galvanised steel of black polypropylene aren’t always ideal, and so we offer brass or stainless steel edging, as well as complete stainless steel covers.

- Q:Why do some nuts and washers, and some nuts without washers

- General screw diameter and the diameter of the fastening parts of the hole is not large, the nut and parts of the contact area is relatively large, you can not add a gasket

- Q:Nominal diameter 12 washers, outside diameter?

- According to?GB/T?95-2002 - C level standard flat washer, nominal diameter (large thread diameter) 12 flat washer, its outer diameter (Max) = 24 mm;(min) = 22.7 mm.

- Q:What is the role of flat washers? There is a friend who can introduce

- Flat washer1 generally used for multiple parts, to increase the bearing surface, covering the larger hole, to prevent damage to the surface of the parts, large washers for wood parts.

- Q:How to remove mildew on the rubber washer

- Solution:1, activated carbon with gauze wrapped and then put;2, orange or orange peel or lemon cut into small pieces, put into steam for a while;3, is not in line with the onion steamed but the effect is poor.

- Q:How do you choose the appropriate gasket for bolt or screw connection?

- When the bolt is connected, the target of the washer is to disperse the material which is connected with the material, reduce the damage to the surface of the material to be connected when the bolt or the nut is reduced, or prevent the loosening of the bolt. When you choose the gasket can be the actual need to relax the use of spring washers, to protect the surface of the material to be connected, optional plain washers. The principle of choice is that the inner diameter of the washer is slightly larger than the outer diameter of the bolt. Screw connection, the use of slightly larger than the location of the largest screw flat washers can be.

- Q:How to use washer, gasket, o-ring "

- Different purposes, the installation position and the corresponding flange are different, if this is how to choose, advantages and disadvantages, too much information

- Q:I would like to ask the car transmission inside the thrust washer (thrust washer) is used to do ah?

- Differential gear thrust washer is composed of silver alloy pressing, as well as plastics. Planetary gear thrust washer and half axle gear thrust washer shape are concave spherical and planar surface, there are many patterns like grooves or concave point in oil storage. The washer is the role of the friction reducing gear and axial differential housing, improve the transmission efficiency of the differential protection shell, thrust face not excessive wear, to prolong the service life of the differential housing, and maintain the normal meshing and transmission differential gear. The reason for the failure of the thrust washer is a serious lack of lubricating oil, or because of the small size of the stay and the erosion. Planetary gear broken, cross shaft fracture caused by the thrust washer damage, is generally rare. When the vehicle is traveling on a special road, or when the vehicle is in the mud, the differential frequency is used, resulting in excessive wear and thinning of the thrust washer. Thrust washer wear will make gear thrust surface shell, thrust surface acceleration loss, the differential gear axial shift, gear meshing clearance increases, the transmission space increases, causing the gear, cross shaft, differential housing bearing seat hole damage. Thus, the thrust washer is a reliable guarantee of differential action, but also to extend the life of differential parts. To this end, the vehicle should be updated on a regular basis when the thrust washer, to restore its proper clearance, to ensure the normal operation of the differential.

- Q:how much Specification for washers

- From 2.5~48, the form of GB/T854-1998, GB/T855-1998, GB/T856-1998

- Q:how to use Motor washer

- Halo, brother, your question also detailed ah, there are a lot of places on a motor washer ah, do you mean where ah, you have to iron or plastic washers, spring washers, I think it is the plastic washer, mainly plastic washer 1 are leak proof, waterproof, anti oil,... 2 insulation, high pressure resistance, 3, vibration reduction, 4, reduce wear, basically on these several functions

- Q:What's the meaning of the "200HV" of the gasket material? Is that the hardness level? What materials are usually chosen? Know predecessors please advice, younger brother is not very grateful!!!

- Washer / gasket material bar indicates that 200HV is the material mechanical performance grade for steel 200HV.Example: standard series, nominal size d=8mm, performance grade 200HV, without surface treatment of flat washers: washers GB97.1 - 858 200HVA part between a connector and a nut. A flat metal ring is generally used to protect the surface of the connecting piece from the nut.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Manhole Cover Heavy Duty Base with Round Cover

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products