M2 Steel Flat Bar for Tool Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

M2 Steel Flat Bar for Tool Steel

Product description:

Size of M2 high speed steel | |||||||||

Round bar | Diameter(mm) | Length (mm) | |||||||

Max:800 | Max: 9000 | ||||||||

Plate | Thickness(mm) | Width (mm) | Length (mm) | ||||||

Max:800 | Max:1000 | Max:6000 | |||||||

The specification can be customized. | |||||||||

Chemical Compositons | |||||||||

Grade | C | Si | Mn | P | S | Cr | Mo | W | V |

W6o5Cr4V | 0.80-0.90 | 0.20-0.45 | 0.15-0.40 | ≤0.03 | ≤0.03 | 3.80-4.40 | 4.50-5.50 | 5.50-6.75 | 1.75-2.20 |

M2 | 0.78-0.88 | 0.20-0.45 | 0.15-0.45 | ≤0.03 | ≤0.03 | 3.75-4.50 | 4.50-5.50 | 5.50-6.75 | 1.75-2.20 |

1.3343 | 0.80-0.88 | ≤0.45 | ≤0.40 | ≤0.03 | ≤0.03 | 3.80-4.50 | 4.70-5.20 | 5.90-6.70 | 1.70-2.10 |

SKH51 | 0.80-0.88 | ≤0.45 | ≤0.40 | ≤0.03 | ≤0.03 | 3.80-4.50 | 4.70-5.20 | 5.90-6.70 | 1.70-2.10 |

Features of M2 high speed steel

1, General purpose of tungsten molybdenum high speed steel; | |||||||||

2, High toughness combined with good cutting powers; | |||||||||

3, Will withstand increases in temperature. |

Typical Applications:

1, Twist drills, reamers, broaching tools, taps, milling tools; | |||||||||

2, Cold forming tools and cutting tools; | |||||||||

3, Plastic moulds with elevated wear resistance and screws.

Packing: silver bright steel packaging : coated with anti-rust oil -plastic film winding -woven cloth winding- -strip steel strapping-wood shipping:according to contract content

|

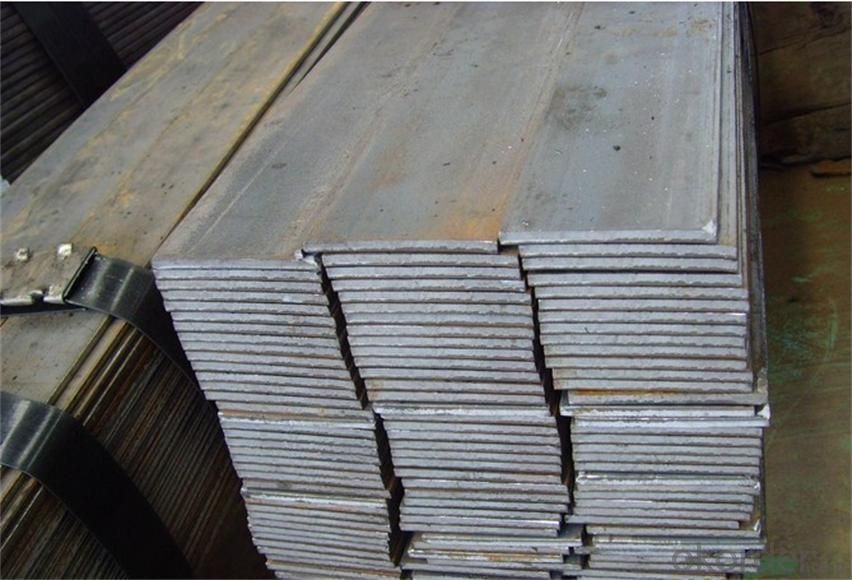

Products show:

- Q:How does special steel contribute to improving product durability?

- Special steel contributes to improving product durability in several ways. Firstly, special steel is known for its high strength and toughness, which makes it more resistant to wear and tear. This means that products made with special steel are less likely to develop cracks, deformations, or other forms of damage during regular use. Additionally, special steel often has enhanced corrosion resistance properties, making it more resistant to rust and other forms of degradation. This helps to prolong the lifespan of products, particularly those exposed to harsh environments or extreme weather conditions. Moreover, special steel can also offer increased heat resistance, enabling products to withstand high temperatures without losing their structural integrity. Overall, the use of special steel in manufacturing processes significantly enhances the durability and longevity of products.

- Q:How does special steel contribute to the telecommunications machinery industry?

- The telecommunications machinery industry heavily relies on special steel for the production of durable and high-quality equipment. This steel is crucial in providing the necessary materials for antennas, satellite dishes, and transmission towers. These machinery are constantly exposed to different environmental conditions and need to endure extreme weather, corrosion, and mechanical stress. Special steel, renowned for its exceptional strength, toughness, and corrosion resistance, ensures the longevity and reliability of telecommunications equipment. For example, antennas and satellite dishes made from special steel can withstand harsh weather conditions and strong winds without compromising signal quality or structural integrity. Moreover, transmission towers, which play a vital role in efficient signal transmission over long distances, are manufactured using special steel. These towers need to support heavy equipment, endure dynamic loads, and resist corrosion to maintain uninterrupted communication. The high tensile strength and corrosion resistance of special steel guarantee the stability and longevity of transmission towers, ultimately contributing to the overall reliability of the telecommunications network. Additionally, special steel is utilized in the production of cables and connectors used in telecommunications systems. These components require high conductivity, low resistance, and resistance to wear and tear. By incorporating special steel, manufacturers of telecommunications machinery can ensure efficient signal transmission and reduce signal loss, leading to improved communication quality. In conclusion, special steel is indispensable in the telecommunications machinery industry as it provides superior strength, durability, and corrosion resistance. By incorporating special steel into the production of antennas, satellite dishes, transmission towers, cables, and connectors, the industry can deliver reliable and high-quality telecommunications equipment to meet the increasing demands of the modern world.

- Q:What are the properties of aluminum alloys?

- Aluminum alloys possess several properties that make them highly desirable in various industries. These properties include lightweight, excellent corrosion resistance, high strength-to-weight ratio, good formability, and electrical conductivity. Additionally, aluminum alloys can be easily cast, machined, and welded, making them highly versatile in different applications.

- Q:How does special steel perform in tooling applications?

- Special steel performs exceptionally well in tooling applications due to its high strength, durability, and resistance to wear and abrasion. It is specifically designed to withstand the demanding conditions of tooling environments, such as cutting, shaping, and forming various materials. The unique properties of special steel, including its excellent hardness and toughness, make it an ideal choice for producing reliable and long-lasting tools that can efficiently handle heavy workloads and maintain their performance over time.

- Q:How does special steel contribute to the electrical resistance of products?

- Special steel can contribute to the electrical resistance of products in several ways. Firstly, the composition of special steel can be tailored to have specific electrical properties, such as resistivity. By selecting the appropriate alloys and adjusting the carbon content, special steel can be made to have higher resistivity than regular steel or other materials. This higher resistivity is beneficial in applications where electrical conductivity needs to be limited. For example, in electrical wiring, the use of special steel with higher resistivity can help to prevent excessive current flow, reducing the risk of overheating and potential electrical hazards. Similarly, in electrical resistors, the use of special steel can provide the desired level of resistance to control the flow of current and dissipate energy in a controlled manner. Special steel can also contribute to electrical resistance through its physical properties. The microstructure of special steel can be engineered to enhance resistance to electrical current flow. For instance, the addition of certain alloying elements or heat treatment processes can create a fine-grained structure or introduce barriers to electron movement, increasing the overall resistance. Furthermore, special steel can be used in the production of electrical contact materials. These materials need to have specific electrical and mechanical properties to ensure reliable and efficient electrical connections. Special steel alloys can provide high electrical conductivity while also being resistant to corrosion, wear, and deformation, thus contributing to the overall electrical resistance of the product. In summary, special steel contributes to the electrical resistance of products through its tailored composition, which can provide higher resistivity than regular steel. Additionally, the microstructure of special steel can be engineered to enhance resistance to electrical current flow. Whether it is used for limiting current flow, controlling resistance, or creating reliable electrical contacts, special steel plays a crucial role in various electrical applications.

- Q:What are the applications of special steel in the oil and gas supply chain?

- Special steel has various applications in the oil and gas supply chain. It is commonly used in the construction of pipelines, drilling equipment, and offshore platforms. Special steel's high strength, corrosion resistance, and ability to withstand extreme temperatures make it ideal for these applications. Additionally, special steel is used in the manufacturing of valves, fittings, and other components that are crucial for the efficient and safe operation of the oil and gas supply chain.

- Q:How does special steel contribute to the electronics industry?

- Special steel contributes to the electronics industry by providing crucial components and materials that enhance the performance, durability, and efficiency of electronic devices. It is commonly used in the production of circuit boards, connectors, and various electronic components due to its excellent conductivity, heat resistance, and corrosion resistance properties. Additionally, special steel is utilized in the manufacturing of precision tools and equipment used in the production and assembly of electronic devices. Overall, special steel plays a vital role in ensuring the reliability and functionality of electronics, enabling advancements in technology and innovation within the industry.

- Q:How does special steel contribute to the performance of industrial machinery?

- Special steel contributes to the performance of industrial machinery by providing enhanced strength, durability, and resistance to corrosion and wear. It enables the manufacturing of components that can withstand high temperatures, heavy loads, and harsh operating conditions, thereby improving the overall efficiency and lifespan of the machinery. Additionally, special steel alloys offer excellent machinability and formability, allowing for precise and complex designs, ultimately enhancing the functionality and reliability of industrial machinery.

- Q:How does special steel contribute to the defense equipment industry?

- The defense equipment industry heavily relies on special steel, which offers superior strength, durability, and performance characteristics essential for manufacturing high-quality military equipment. This type of steel is specifically engineered to meet the demanding requirements of defense applications, ensuring the safety and effectiveness of military personnel and operations. A significant contribution of special steel to the defense equipment industry lies in its ability to withstand extreme conditions and environments. Military equipment often operates in harsh conditions, including extreme temperatures, high pressures, corrosive environments, and impact forces. Special steel is designed to maintain its structural integrity and performance under these challenging conditions, providing a reliable and long-lasting solution for defense equipment. Furthermore, special steel possesses exceptional strength and toughness, making it optimal for producing armored vehicles, tanks, and military aircraft. It provides a high level of protection against ballistic threats and can endure projectile impacts and explosions. The utilization of special steel in defense equipment guarantees the safety of military personnel and enhances their survivability in combat situations. Additionally, special steel is indispensable for the production of cutting-edge weaponry and munitions. It is employed in the manufacturing of firearms, missiles, and artillery systems due to its excellent mechanical properties and ability to withstand high pressures. Special steel also enables precision engineering, ensuring the accuracy and reliability of military firearms and projectiles. Moreover, special steel contributes to the defense equipment industry by supporting technological advancements. As technology continues to evolve, the defense sector requires materials that can meet the demands of modern warfare. Special steel can be tailored and optimized to meet specific performance requirements, allowing for the development of advanced defense systems such as stealth technology, electronic warfare, and precision-guided munitions. In conclusion, special steel plays a crucial role in the defense equipment industry by providing the necessary strength, durability, and performance characteristics required for military applications. It guarantees the safety and effectiveness of defense personnel and equipment, withstands extreme conditions, facilitates the production of advanced weaponry, and supports technological advancements in the defense sector.

- Q:How long does special steel last compared to regular steel?

- Special steel generally lasts longer than regular steel due to its unique composition and properties. Regular steel is made mostly of iron and carbon, whereas special steel is alloyed with other elements such as chromium, nickel, and molybdenum to enhance its strength, hardness, and corrosion resistance. The lifespan of special steel depends on various factors such as the specific type of steel, its usage conditions, and maintenance. However, in general, special steel can have a significantly longer lifespan compared to regular steel. It is more resistant to wear and tear, corrosion, and high temperatures, making it suitable for demanding applications and environments. For instance, in industries such as aerospace, automotive, and construction, special steel is widely used for critical components like engine parts, structural elements, and cutting tools. These components often experience high stress, friction, and exposure to harsh conditions. Special steel's superior properties enable it to withstand these challenges and maintain its performance over a longer period of time. Moreover, special steel is often subjected to rigorous testing and quality control measures during its manufacturing process. This ensures that it meets specific industry standards and can endure extreme conditions without significant degradation. Regular steel, on the other hand, may not possess the same level of durability or longevity. In summary, while the exact lifespan of special steel compared to regular steel can vary depending on various factors, special steel generally lasts longer due to its enhanced properties and resistance to wear, corrosion, and high temperatures.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

M2 Steel Flat Bar for Tool Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords