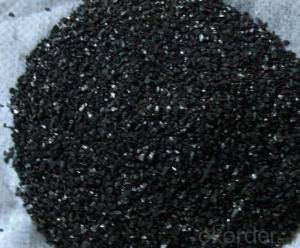

Low moisture Silicon Carbide in good quality made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Introduction

1. Silicon carbon can be used as metallurgical deoxidizer and high temperature resistant materials in smelting.

2. It can also be used as abrasive materials,which can be used to make abrasive tools,such as grinding wheels, oilstones, grinding head and so on.

2. Features

Silicon carbon is a new kind of reinforced steel-making deoxidizing agent and ideal thermal insulating agent.it is used for deoxidizing. The usage dose is 1-4kg/t can make electricity consumption to reduce 15-20kw/h and time to reduce 15-20min per furnace to raise productivity rate to 8-10%.

With high quality, reasonable price and timely delivery, our products have been export to many foreign countries and areas, such as South Korea, Japan, Turkey etc. our company has got praise in both domestic and foreign markets.we have been the trusted and preferred supplier to the mineral&chemical products and the market share is growing rapidly and firmly. Warmly welcome all friends from domestic and abroad to cooperate with us

3. Specifications:

Grade | Sic% | FreeC% | Si+SiO2% | Fe2O3 | MgO% | H2O% |

Sic75 | 75±4 | 2.5±1 | 17±2 | 3 | 0.16 | <5< span=""> |

Sic65 | 65±4 | 4.5±1 | 23±2 | 4 | 0.12 | <5< span=""> |

Sic55 | 55±4 | 4.8±1.5 | 28±3 | 5±2 | 0.1 | <5< span=""> |

Sic45 | 45±4 | 5±2 | 31±3 | 7±2 | 0.1 | <5< span=""> |

4. FAQ:

(1) Large melting furnace, longer melting time, lead to more crystallization, bigger crystals, higher purity and less impurities.

(2) Good hardness, longer life. it is better and better this time

(3) Chemical washed and water washed good cleanness.

(4) Special treated products get higher purity, better toughness, and better grinding effect.

1.Sample for free for your test.

2.Provide professional product consultation.

3.Offer competitive price.

4.Have precise quality control department.

5.Taking photos during the production and shipment, send the photos to customers;

6. Documents Department, to serve customer professionally.

7.Always think of the customers and make the add-value.

5. Pictures

- Q:Advantages and disadvantages of coalSuch as the titleThe advantages and disadvantages of LPG also help to say it

- There is a growing shortage of resources and a lack of adequate combustion

- Q:Is it useful to use bamboo charcoal bags? Bamboo charcoal package is activated carbon? Want to buy one, do not know how to choose?

- To buy real activated carbon, activated carbon, then the price is higher than the price of bamboo charcoal, a penny of goods, is not a joke.

- Q:What is the proportion of dry activated carbon

- The other kind of admixture is ash, which is the inorganic part of activated carbon, and ash can easily cause two pollution in activated carbon.

- Q:How many years can the world's oil and coal be mined?

- Although the reserves in the formation of oil and gas cannot be accurately estimated, but the oil experts on oil reserves for a rough estimate: the human to obtain the earth since 1973 a total of 500 billion barrels (about 800 tons) of oil, accounting for the time proven reserves of 85%;

- Q:How long the activated carbon tank. It will fail, there will be any fault

- Carbon canister (Valve EGR) is used to recover fuel vapor.Working principle of carbon canisterIn order to reduce the environmental pollution caused by the gasoline vapor in the fuel tank and improve the fuel economy, the modern car controls the fuel evaporation. The fuel vapor in the tank is adsorbed by activated carbon in the canister.

- Q:What kind of pesticide chili pepper

- Anthracnose is one of the most frequently occurring diseases on hot (sweet) pepper. Can cause pepper leaves, rotten fruit, seedling death. General harm is not serious, but in rainy years, the incidence of severe. According to its symptoms can be divided into 3 kinds of black anthracnose, black spot anthrax and red anthrax

- Q:What is the difference between wood activated carbon and coal activated carbon

- In the field of gas phase adsorption: coal activated carbon products high strength and easy recycling, so often used in gas phase adsorption; activated carbon intensity is low, not traditionally used for gas phase adsorption, however, with the advancement and improvement of production technology, application of wooden activated carbon has been expanded to some the new gas adsorption fields such as oil and gas recovery, household air purification, and with the people for health and environmental protection to improve the level of attention, in the gas phase adsorption and its application in the field of space will be further increased.

- Q:The standard Meizhi is what mean?

- There are many kinds of energy, the heat is also different, in order to facilitate mutual comparison and in the total amount of research, China's 7000 kg per kilogram of hot water (29 million 306 thousand coke) as standard coal, also known as standard coal. In addition, China has often energy converted into standard coal tonnage to 1 tons of straw, such as the energy equivalent to 0.5 tons of standard coal, 1 cubic meters of methane energy equivalent to 0.7 kilograms of standard coal.

- Q:What can coal do? Where do you come from?

- (2) coking coalAlthough our country is rich in coal resources, coking coal resources are relatively small, coking coal reserves account for only 27.65%.Coking coal includes coal (13.75%), (3.53%) coal, coking coal, lean coal (5.81%) (4.01%), the other is divided into grades of coal (0.55%); non coking coal includes anthracite (10.93%), coal (5.55%), alkaline coal (1.74%) do not pay, coal (13.8%), coal (12.52%), brown (12.76%), natural coke (0.19%), not the grades of coal (13.80%) and grade of coal is not clear (1.06%).The main purpose of the coking coal is coke, coke or mixed coal coking coal by high temperature smelting, 1.3 tons of coking coal order a ton of coke. Coke used for steelmaking, is currently the main raw material for the production of iron and steel industry, iron and steel industry has been hailed as the "basic food", is one of the important raw materials in the world raw materials in the world market.

- Q:What industry is washed coal

- (1) anthracite (WY). Anthracite has high carbon content, low volatile yield, high density, high hardness and high ignition point. 01 anthracite for the old Anthracite; anthracite coal for the typical anthracite, anthracite coal No. 03 for the young anthracite, No. 02. Such as Beijing, Jincheng, Yangquan were 01, 02, 03 anthracite.(2) lean (PM). Coal is a high degree of coalification coal, non caking or slight caking. Non coking in layered coking furnace. Short flame, burning resistant.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Low moisture Silicon Carbide in good quality made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products