Anthracite Steel Making Coal Anthracite 6450 Kcal/Kg

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Anthracite Description

Anthracite is made from Shanxi,the coal capital of the word .The quality is very high due to its unique resource .It has been exported to most of the world ,especially to Japan and Korea,as well as mid east.

It is commonly used in drinking water ,food industry ,chemical /dyeing industry ,sea/salt water filtration ,petro-chemical industry ,pulp/paper industry ,sauna,spa,pool,boiler ,etc.

Advantages:

1. Longer Filter Runs2. Faster Filtration3. Long Lifetime4. Good Separation Characteristics5. Savings water and power in washing6.Removes more iron and manganese salts tration ,petrochemical industry ,pulp /paper industry ,sauna,spa,pool,boiler,etc.

2. Main Features of Anthracite

Fixed Carbon: 78 %

Ash: 18 %

Volatile Matter: 4 %

Sulphur: 1.0 %

Moisture: 11 %

Gross Calorific Value: 6450 Kcal

Size: 0 mm - 19 mm: 90%

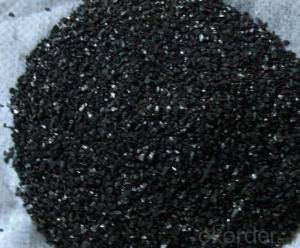

3. The Images of Anthracite

4. The Specification of Anthracite

1. Fixed carbon: 90%min

2.Uniform particles

3.Good separation characteristics

4. Long life

5. Widely used

6.activated anthracite:

7.Certificate: ISO9001, ISO9002, NSF

8.Usage: for water and air purification, etc.

5.FAQ of Anthracite

1). Q: Are you a factory or trading company?

A: We are a factory.

2). Q: Where is your factory located? How can I visit there?

A: Our factory is located in ShanXi, HeNan, China. You are warmly welcomed to visit us!

3). Q: How can I get some samples?

A: Please connect me for samples

4). Q: Can the price be cheaper?

A: Of course, you will be offered a good discount for big amount.

- Q:Charcoal ash can do what you can do with it? emergency

- Charcoal ash fertilizer application:1 separate application. Not with organic manure (human waste, manure, compost fertilizer, etc.) and ammonium nitrogen fertilizer combined application, so as to avoid the losses of nitrogen and phosphorus; nor mixed application, so as to avoid phosphorus fixation, reducing phosphate fertilizer.2 Soil application. Because it is alkaline, it is advisable to use clay, acid or neutral soil. Soil can be used as base fertilizer, fertilizer and fertilizer, but also covering for seedling, seedling (cover for fertilizer). As base fertilizer, fertilizer, fertilizer and seeds can not be too large and should be isolated to prevent a fire. The amount of acre is generally 50 - 100 kg. Soil is suitable to application, and can be used in banding 8, depth of 10 cm, after application of soil. Mix 2 to 3 times before applying wet soil or spray with a little water.3 top dressing. Ash contained in the ash, more than 90% of soluble in water, for quick acting potassium fertilizer. According to this characteristic, it can be used as fertilizer for root, that is, using the concentration of 1% of the charcoal ash leaching solution.

- Q:And I know I need to clean it. It is best to filter out the stones out. But it is sealed. How to deal with?

- How to clean the activated carbon filter rodAnd I know I need to clean it. It is best to filter out the stones out. But it is sealed. How to deal with?The name was upset | browse 2591Recommended 2016-12-03 13:35:21 best answerCleaning method of activated carbon filtration equipment for drinking machine:1, the outer ring winding line, pipe and net should be washed with high pressure water, light brush, and soaked in bleach solution for one hour, then rinse off with clean water.2, a simple cleaning method for granular activated carbon from activated carbon particles, with water several times and then put it back.3, granular activated carbon the correct cleaning method, dilute hydrochloric acid for four hours, rinse clean water, and then oven drying at room temperature for three hours, remove and then rinse with water, can restore its activity.The filter layer of the water dispenser is essentially a filter paper layer, an activated carbon layer, a stone layer and an ion resin layer. According to different water quality, the filter layer filtering ability, service life is different, in general, the 2-3 filter should be cleaned once a month, a year or so replace the filter, if the water quality is good, the use of time will be appropriate to long, with no smell for water.

- Q:Why is heating charcoal poisoning??

- 1 the use of charcoal stove in the house must open the window ventilation, to ensure the flow of air.2 in case of carbon monoxide poisoning, should temporarily leave the poisoning site, breathe fresh air, call someone to help.3 officers found poisoning, should immediately open the window, the patient carried away from the scene, loosen buttoned, maintain airway patency and warm.4 if vomiting should make the patient head to one side, and timely cleaning the nasal cavity secretions.5 people with hand pinch poisoning, Zusanli, Neiguan and other points in a timely manner oxygen, such as suffocation, immediately artificial respiration and chest compressions.6 rushed to hospital for treatment.

- Q:What is the specific coal chemical

- The process of converting coal into gas, liquid and solid fuels and chemicals from coal. Mainly including coal gasification, liquefaction, distillation, as well as tar processing and calcium carbide acetylene chemical

- Q:Bamboo charcoal bag placed in the room

- If you want to live in as soon as possible, there are several methods to help: 1 to half a catty Black Tea soaked with boiling water, the water drained, Black Tea will put a pot (that is, table container area comparison), placed in the room, or directly on the furniture inside, the surface of tea has strong adsorption capacity, can absorb indoor harmful gas as the size of the room, can get many pots. Place more than 24 hours, there will be significant improvement. More than and 2 some green plants, such as Chlorophytum, Sansevieria, ivy, also have the effect

- Q:Steam conversion standard coal1 tons of steam (per kg enthalpy: 220 -260 C of steam calculated according to the 680 thousand card) = how many tons of standard coal?In this case, what is the conversion coefficient of steam?Where can I find the conversion coefficient of steam?

- International legal provisions low calorific value of 29308 kJ/kg (7 million card / kg)

- Q:How to convert tons of coal into electricity?

- 1000KG*0.7143/0.404=1768 power.1 tons of coal can be issued to 1768 degrees.

- Q:Please introduce in detail, thank you, and there is no machine production of charcoal

- There are two kinds of preparation methods:(1) the kiln, with mud kiln, filled with wood burning from the kiln door or door, the carbonization of wood in the kiln, volatiles escape and residual charcoal;

- Q:Usually we use coal as fuel to get heat in the process of combustion, but many harmful substances are discharged into the environment at the same time as waste. By referring to the information and refer to the schematic, please write in order to save resources, reduce waste, how should we make full use of coal?Urgently ahThe sketch map of which include: rubber, explosives, essence, nylon, coke, liquefied gas, gas......Thank you pull

- Usually we use coal as fuel to get heat in the process of combustion, but many harmful substances are discharged into the environment at the same time as waste. By referring to the information and refer to the schematic, please write in order to save resources, reduce waste, how should we make full use of coal?Urgently ahThe sketch map of which include: rubber, explosives, essence, nylon, coke, liquefied gas, gas......Thank you pull

- Q:Coal formation process and time

- The thickness of coal seam in a coal mine and the crust drop speed and accumulation amount of plant remains. The crust decreased rapidly, the plant remains piled thick, the coal seam is thick, on the other hand, the crust decline slowly, the accumulation of plant remains thin, the mine coal seam is thin. The tectonic movement of the crust to the original level of coal seam folds and faults occur, some underground coal seam buried deeper, and squeezed to the surface, even above the ground, more likely to be found. There are some relatively thin coal seam, and the area is not large, so there is no value related to the formation of coal mining, so far not find the update statement.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Anthracite Steel Making Coal Anthracite 6450 Kcal/Kg

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches