large roof wall color steel composite and modified phenolic fireproofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

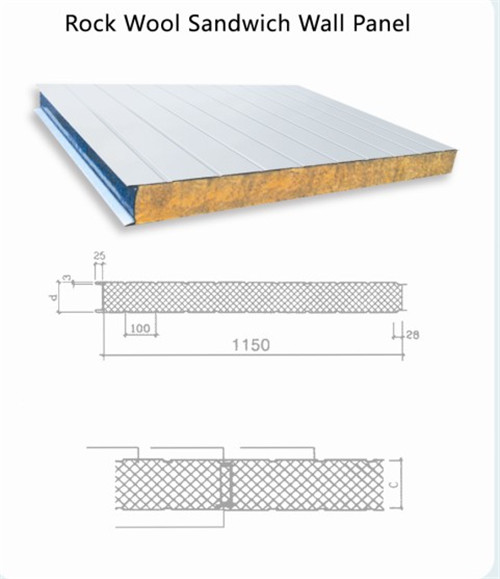

| Place of Origin: | Hebei China (Mainland) | Brand Name: | wzh | Model Number: | 950/1150mm for wall or ceiling or 950mm as roof |

| Panel Material: | Metal | Type: | Rock Wool Sandwich Panels | Thickness: | 50/75/100/125/150/200 mm |

| Color: | Many color are available, but white grey, sea blue and bright red | Materials: | Rockwool, EPS, PU sandwich and two sides are oosteel sheet | Certification: | ISO9001&ISO14001 |

| Name: | sandwich panel; coposite panel;steel plastic composite pannel | Length: | as your require | Effective width: | 950/1150mm for wall or ceiling or 950mm as roof |

| Utilisation: | prefabricated house, container house,cold room | Kinds: | roof panels; wall panels | Charastic: | heat perservation; waterproof |

Packaging & Delivery

| Packaging Detail: | standard export pallet,with protective corner guard and film on the four sides |

| Delivery Detail: | 15 days after recieved despoit |

Specifications

EPS composite board rockwood composite board glassfiber composite board

Light weight

High intensity Sound proof Easy installat

EPS composite board rockwood composite board glassfiber composite board

The usual sandwich panels include rock wool Sandwich panel, EPS sandwich panels, PU Sandwich Panel, glass fiber sandwich pannels. The up & down surface of this panel is Galvanized & Prepainted steel sheets, core material is rock rood, EPS, PU, and glass fiber. It is formed by heating, foaming & laminating. It is the best material for temperature keeping and sound insulation. It is widely used as the wall or roof for cold storage, industrial workshop, public building etc.

Specifications

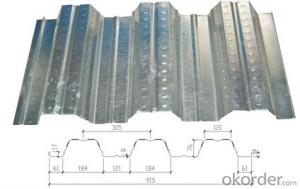

(1)Core Material: Rock Wool, EPS, PU; Surface Materials: Galvanized Steel sheets or Prepainted Steel sheets.

(2)Wall Thickness: 40, 50, 60, 80,100,120,150,180,200,250mm

(3)Max. Width: 1200mm

(4)Length: according to client's demands, engineering requirements and shipment conditions

(5) Application: for ceiling & wall, partition wall

(6) Widely used in common steel structure and storey adding projects,e.g. adding storey to small steel structure industrid factory building worehouse,suburbon temporary office,residentid quarters,school,hospital,etc.

Characteristics

1) With a light weight, a giraffe fitting and random incise characteristic, the fitting is much simpler, and it can advance the benefit and save the time limit for a project

2) Color coated sandwich panel's surface material and heat preservation material are non-burn or hard-burn materials, entirely satisfy the fireproofing criterion request

3) Manifold disquisition and oversea used approving more than 40 years. By especial coated dispose, the color coated steel panel's guaranty is 10-15 years, and the panel's life express 35 years by painting the antisepsis material after each 10 years

4) Pressing steel panel with the clear line, and many colors for choice, and suit with any different building style materials, achieving the satisfying effects.

5) In common use heat preservation materials are rock-wool, polystyrene,

polyurethane, all with lower thermal conductivity and favorable heat preservation and heat insulation effects

6) Sound insulation intension can be 40-50dB, it is the most effective sound insulation material

7) Pressing steel panel can be arbitrariness incise, it can satisty the especially design demands

8) Use the high strength steel panel for the base metal (contradict open and pull intension 5,600kg/cm2), adding the most advanced design and roll pressing moulding, it gets the best structure character

9) Improves speediness and springiness designs according to clients' requirements.

- Q:Is the picture below the S modeling faculty do very stiff want to achieve this and exactly the same effect Thank you!

- Hello, you should explain what it is to use, where to use. We do the shape of the ceiling, then, are generally made with multi-layer board, in accordance with the requirements in the multi-layer board first arc, and then use the curve machine or trimming machine and other equipment cut.

- Q:Is Qu Mei 's sheet green?

- Hello, I am pleased to answer for you, the plate can be used directly to fish, seen in the store, a friend home decoration is the song home custom home, very good, hope to help you

- Q:PCB plate manufacturers are famous what

- Sunrise, Matsushita, Arlon, Nelco, Rogers, Tanconic, polyflon, etc.

- Q:What are the classification of timber for construction?

- Fir: Metasequoia glyptostroboides, fir, spruce, hemlock Pine: northeast pine, yellow flowers pine, larch, Pinus massoniana, China pine, pine, red pine Willow: Ash, Willow Elm: elm Birch: birch, redwood Yang: Maple Leaves, Poplar Oak: oak, green grass and many more.

- Q:Board grade divided into

- Environmental protection level E0, E1, E2, etc., E0 most environmentally friendly, home decoration is best not to use E2 level

- Q:Q235 material, 2.5mm thickness of the plate, flanging R corner of the smallest can not be less than how much? Is a material thickness? This problem is applied to similar flanging situation? Do sheet metal peers please help

- The minimum radius of the bend is 0.3t in the direction perpendicular to the rolling pattern, 0.8t parallel to the rolling pattern, and the minimum radius is 0.5t when it is at an angle of 45 ° to the rolling direction.

- Q:The production of melamine sheet

- Melamine board Melamine board, full name is melamine impregnated film paper facing wood-based panel. Is to put the paper with different colors or textures into the melamine resin adhesive soak, and then dry to a certain degree of curing, will be paved in the particleboard, medium density fiberboard or hard fiber board surface, made by hot pressing plate. In the production process, usually by the combination of several layers of paper, the number of depending on the number of purposes. General sub-surface paper, decorative paper, covered paper and the underlying paper and other components. Surface paper, is placed on the top of the decorative plate, from the role of decorative paper, so that after heating and pressing the surface of the plate highly transparent, hard surface hard wear, this paper requires good water absorption, white and clean, transparent after dipping. Decorative paper, that is, wood grain paper, is an important part of decorative panels, with a background or no background, printed on a variety of patterns of decorative paper, placed under the surface paper, mainly from the decorative effect, this layer requires paper Has good hiding power, impregnation and printing performance. Cover paper, also known as titanium white paper, generally in the manufacture of light decorative panels, placed under the decorative paper to prevent the underlying phenolic resin through to the surface, its main role is to cover the surface of the substrate color spots. Therefore, require a good coverage. The above three kinds of paper were soaked with melamine resin. The bottom of the paper, is the decorative board of the base material, the board from the mechanical properties of the role is impregnated with phenolic resin by drying, the production can be used according to the thickness of the plate or to determine a number of layers.

- Q:Fuqing plate quality how

- Fuqing plate quality is still very good, listen to the sale of Fuqing plate market, said: "Fuqing" brand is China's first registered trademark in Japan plate enterprises, Fuqing exports of Japanese sheet metal and similar products accounted for the country First, "Fuqing sheet" comprehensive through the ISO9001 international quality management system certification, the Chinese environmental labeling product certification, FSC forest certification, Japan's highest level of quality management system JAS certification, the product has reached Japan F ★ ★ ★ ★ level, the European E0 Environmental standards.

- Q:Plate fire rating, such as glass magnesium board incombustibility to A1 level, how to distinguish these, how many fire rating?

- If it is a real glass magnesium board can reach a level, because he can use the material to make him a level

- Q:What is the HS code of the PVC sheet?

- 39202017.00 PVC board 39204300.90 recycled PVC board 39204300.90 PVC board 39204300.90 color PVC board 39204300.90 color printing PVC board 39204300.90 PVC PVC board 39204900.90 anti-static PVC board 39219090.00 color PVC board 39261000.00 PVC board clip 39269090.00 PVC board display stand

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

large roof wall color steel composite and modified phenolic fireproofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords